Radioactive waste liquid treating method, radioactive waste liquid treating device and facility

A technology of radioactive waste liquid and treatment device, which is applied in the fields of radioactive waste liquid treatment, radioactive waste liquid treatment device and equipment, can solve the problems of high disposal cost, large amount of radioactive solid waste, shortened cycle of ion exchange resin, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0095] The adsorbent used in this example is a self-developed micron-sized magnetic core-coated ferrocyanide cesium-removing adsorbent (Chinese invention patent ZL201210347269.8). The experimental adsorbent to the target nuclide Cs + removal performance. The adsorbents of 20g / L, 40g / L and 60g / L were flowed into the reactor for batch experiments to study the effect of adsorbents on the Cs in the solution. + the adsorption situation. Radioactive waste liquid using CsNO 3 Prepared by dissolving in tap water (conductivity about 980μs / cm, corresponding to salt concentration 550-750mg / L), Cs + The concentration is 1.5mg / L. Within 13min of stirring the reaction under the condition of 300rpm, select a specific time point to sample (the ratio of the sampling volume to the total volume of the solution is small to negligible), and analyze the Cs + Concentration, calculate the removal rate of Cs (I) by above formula (1). The removal rate under different adsorbent dosage conditions i...

Embodiment 2

[0101] The adsorbent used in this example is a self-developed micron-sized magnetic core-coated ferrocyanide cesium-removing adsorbent (Chinese invention patent ZL201210347269.8). Experimentally determine and verify the gravitational settling time of the adsorbent.

[0102] For the magnetic cesium-removing adsorbent selected in this embodiment, we also tested the experiment of magnetic separation and sedimentation by using an external magnetic field. In the test, an electric coil is wound on the outer wall of the reactor, and an external magnetic field can be generated after electrification, and the adsorbent can be completely absorbed on the inner wall of the reactor within a few seconds, and the rapid separation of solid and liquid phases is completed. Considering that the structural design and operation of the reactor should be simplified as much as possible in the actual operation of nuclear power plants, the magnetic adsorbent was taken as an example to focus on the gravi...

Embodiment 3

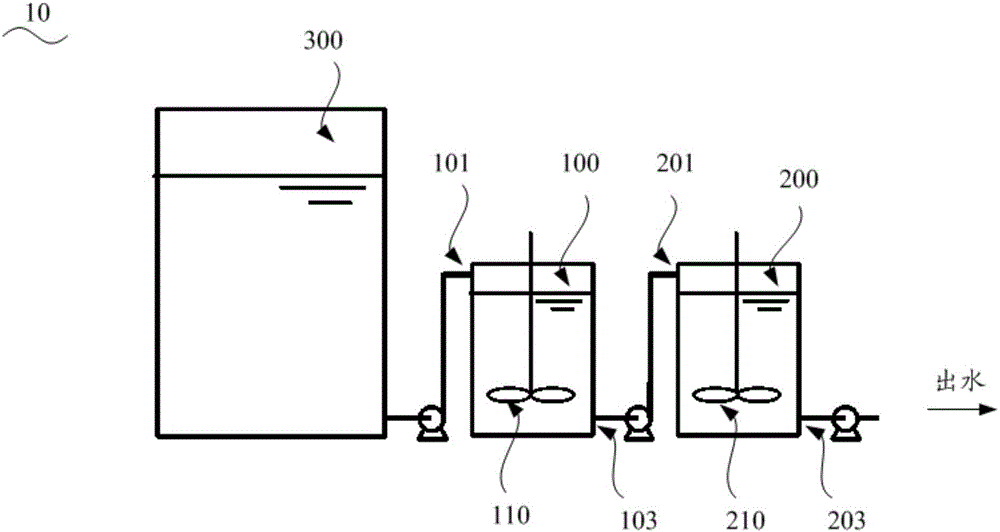

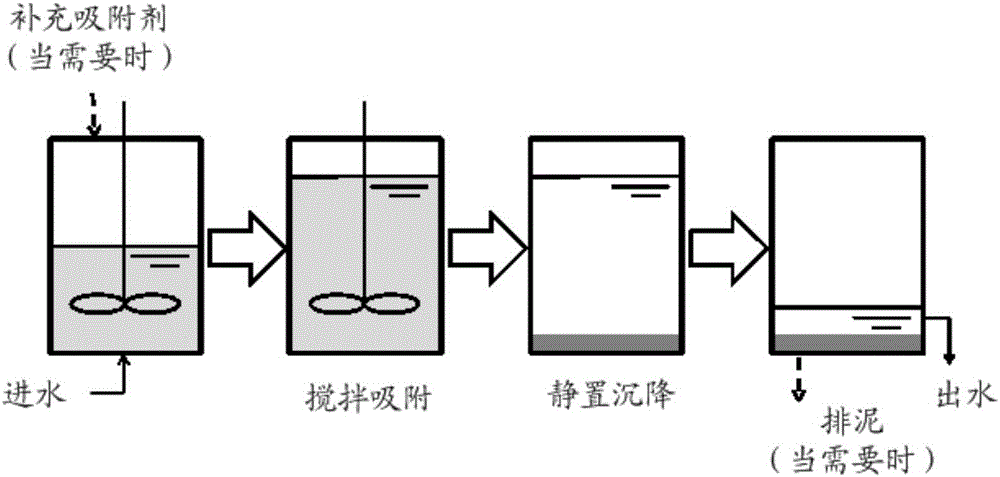

[0110] The first adsorbent used in this example and the second adsorbent are self-developed micron-sized magnetic core-coated ferrocyanide cesium-removing adsorbents (Chinese invention patent ZL201210347269.8). A two-stage sequencing batch reactor was used to test its effect on Cs + removal performance. Under laboratory conditions, using the figure 1 The shown radioactive waste liquid treatment device (two-stage sequencing batch reactor) is used for batch experiments. Among them, the radioactive waste liquid uses CsNO 3 Prepared by dissolving in tap water (conductivity about 980μs / cm, corresponding to salt concentration 550-750mg / L), Cs + The concentration was 1.5 mg / L, and the effective volumes of the first reactor and the second reactor were both 1 L. The feeding mass of the first adsorbent and the second adsorbent flowing into the first reactor and the second reactor is both 40 g, and the amount of each batch of treated water is 1 L. In the experiment, the radioactive ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Median particle size | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap