A zero-degree double crystal pressure-bonding structure and adjustment method

A dual crystal, crystal technology, applied in the direction of connecting components, material gluing, mechanical equipment, etc., can solve the problems of low efficiency and poor alignment accuracy in the uneven operation process of the adhesive layer, and achieve efficient and uniform pressure-bonding curing physical fusion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical solutions of the present invention will be further described in detail below through the accompanying drawings and embodiments.

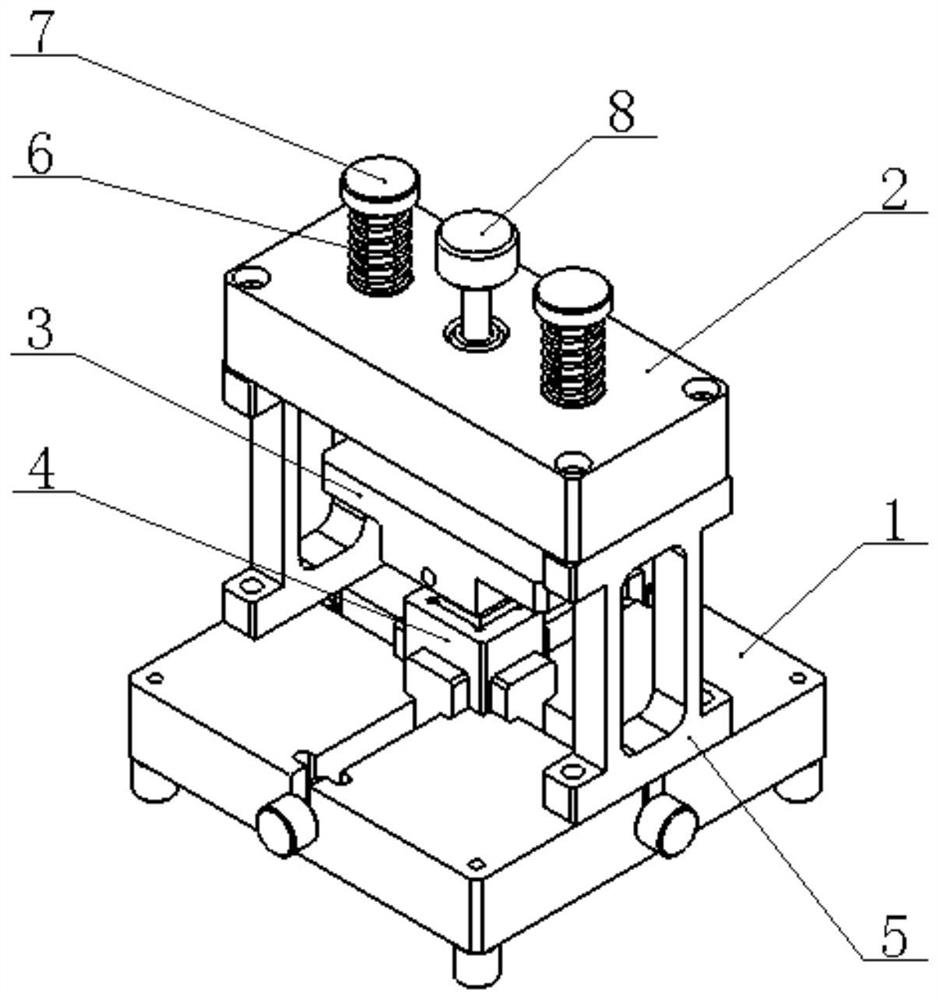

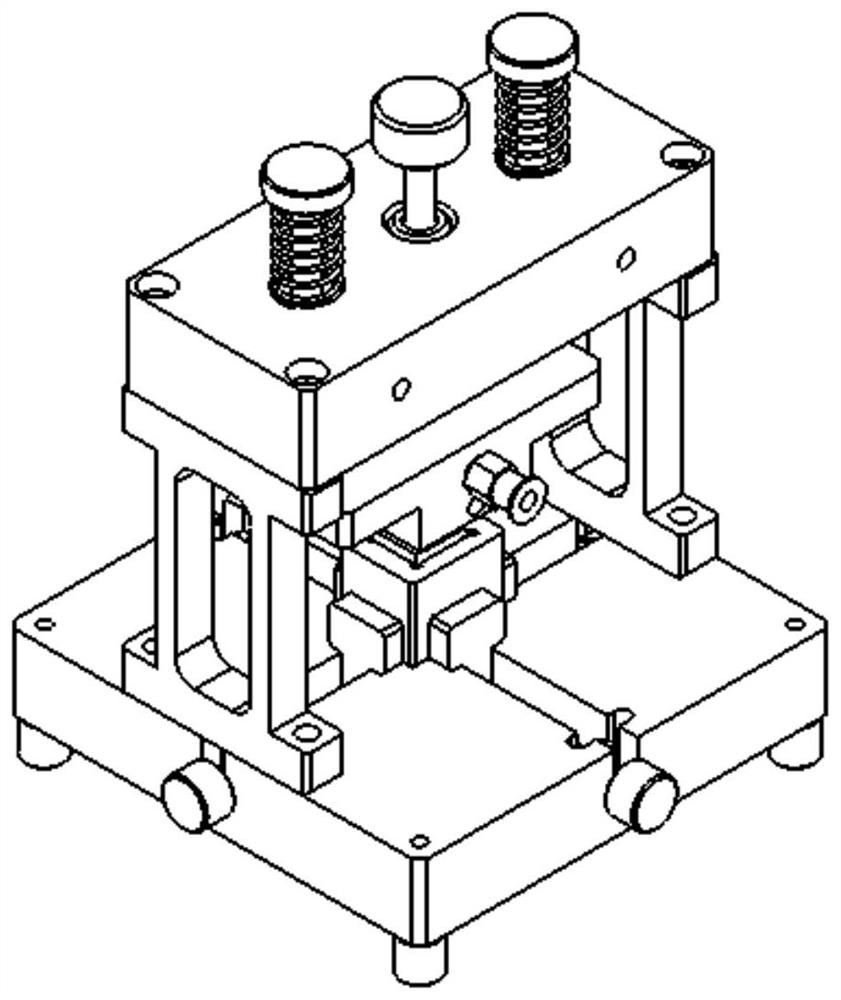

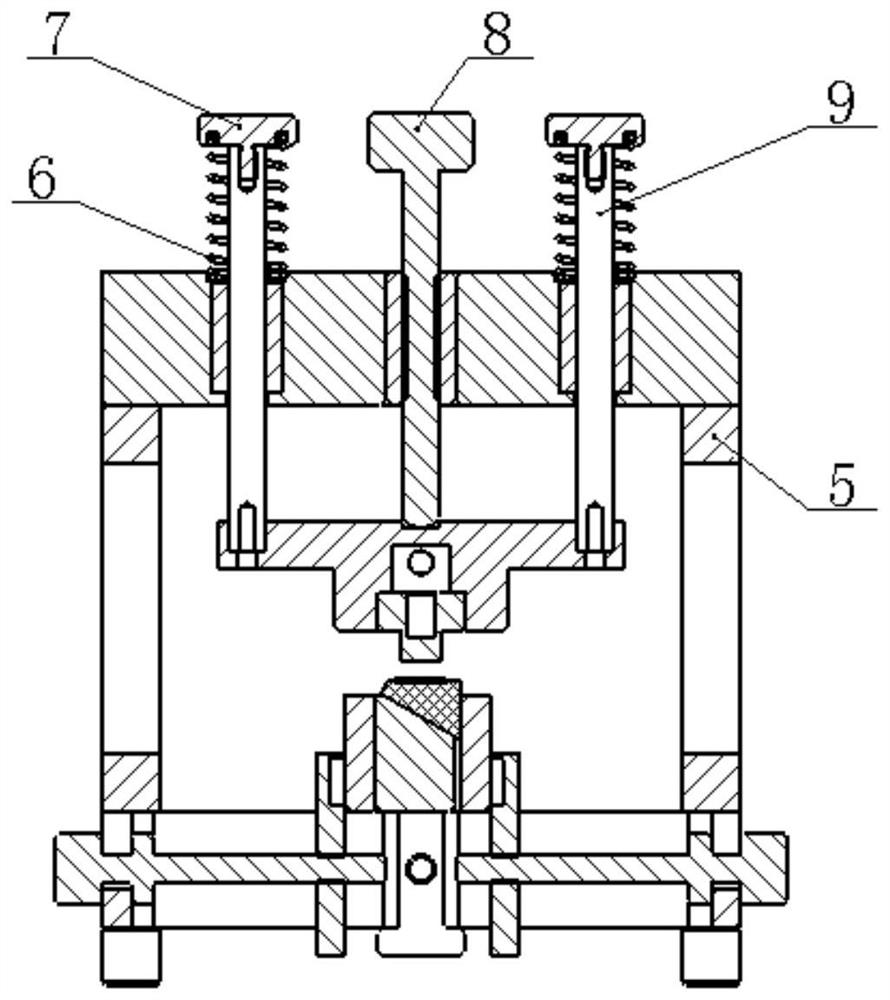

[0026] like Figure 1-Figure 3 As shown in the figure, the zero-degree dual crystal pressure-bonding structure includes: a base unit 1, an upper base unit 2, a suction head unit 3, a mold unit 4 and a force base 5; connected. The upper base unit 2 is provided with a plurality of through holes, and the guide rod 9, which is matched with the suction head unit 3 in the form of a hole axis, is introduced into the through hole corresponding to the upper base unit 2, and then is inserted into the compression spring 6 and then screwed into the compression cover 7, relying on the compression spring. 6. Make the suction head unit 3 in a high position; screw the force-applying screw 8 in a threaded connection with the upper base unit 2 to be combined with the suction head unit 3 . Mold unit 4 (refer to the attached Figure 11-14 ) incl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com