Tea tray assembly

A combination and tea tray technology, applied to trays, mats, drinking vessels, etc., can solve the problems of large volume of the lower tray, labor-intensive cleaning and dredging, and user troubles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

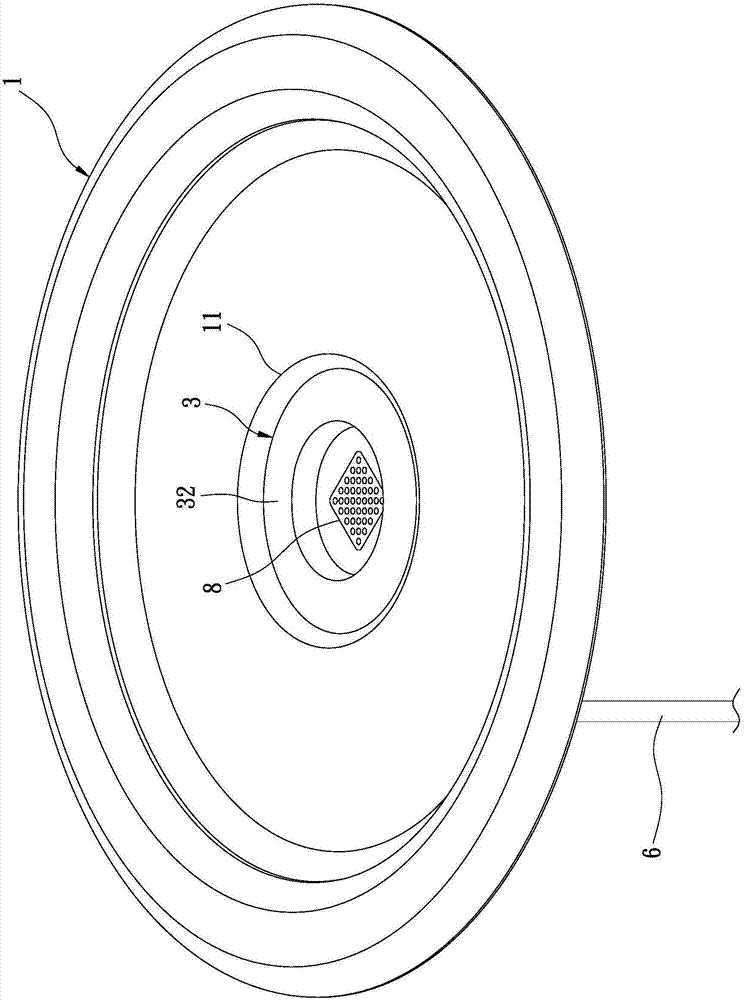

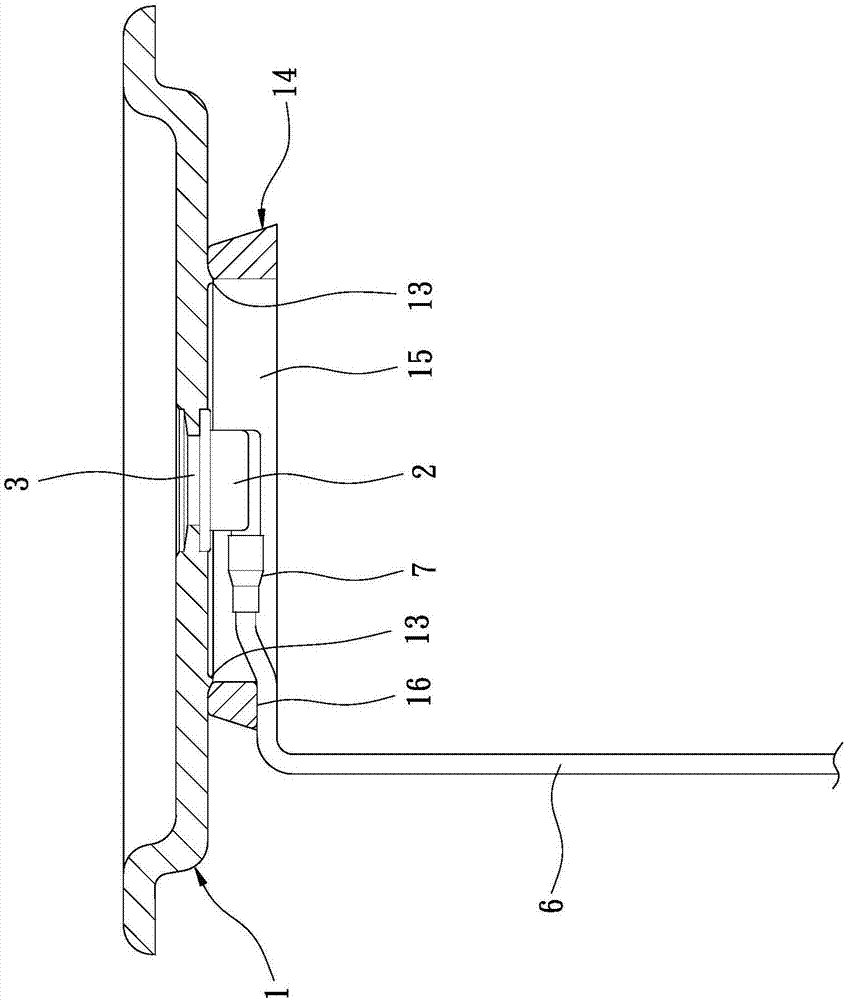

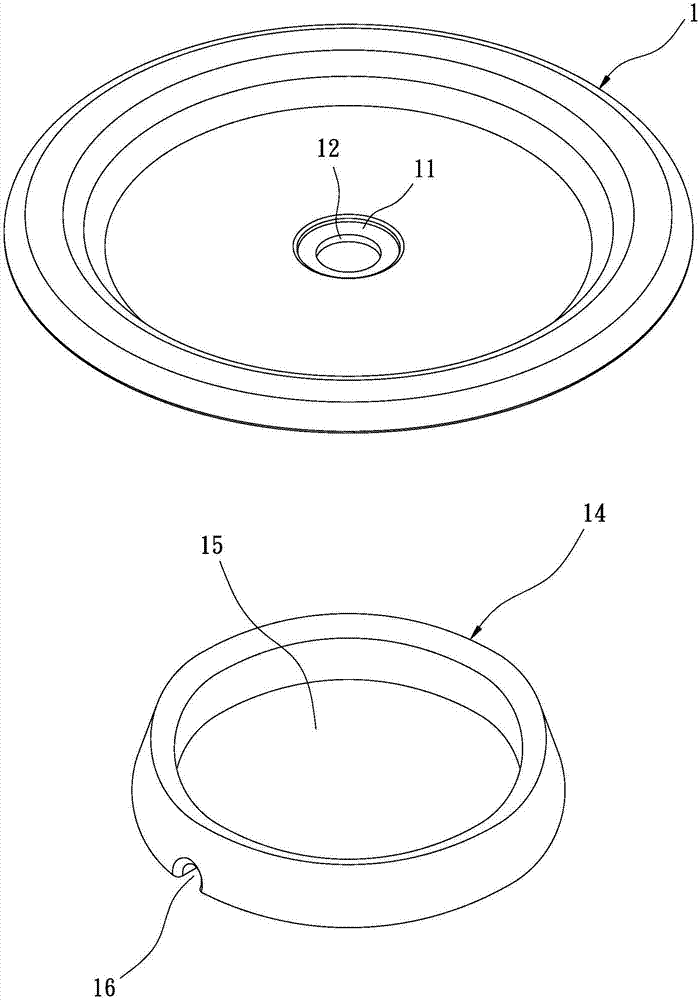

[0046] see Figure 1 to Figure 7 As shown, it can be clearly seen from the figure that the present invention is provided with a disc body 1, a seat body 14, a drainage box 2, a locking member 3, a gasket 4, a connecting pipe 5, a drain pipe 6, a tightening sleeve 7 and a filter plate 8 ,in:

[0047] The surface of the disk body 1 is concavely provided with a positioning groove 11 , the bottom surface of the positioning groove 11 is provided with a positioning hole 12 penetrating through the bottom surface of the disk body 1 , and the bottom surface of the disk body 1 is annularly provided with a positioning rib 13 . An accommodating space 15 is formed in the seat body 14 , and a through hole 16 is provided on one side of the seat body 14 , and the through hole 16 communicates with the accommodating space 15 .

[0048] The drainage box 2 is arranged on the bottom surface of the tray body 1. The drainage box 2 has a main body 21. The interior of the main body 21 is provided wit...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap