Plate member for battery stack

A technology for plate members and fuel cell stacks, applied in fuel cells, electrical components, circuits, etc., to solve problems such as increasing the complexity of the manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The exemplary embodiments described herein are applicable to fuel cell technology, and may provide a plate member for a cell stack. For example, bipolar plates can be provided that can simplify the assembly process of proton exchange membrane fuel cell (PEMFC) stacks, improve stack performance, and reduce manufacturing costs.

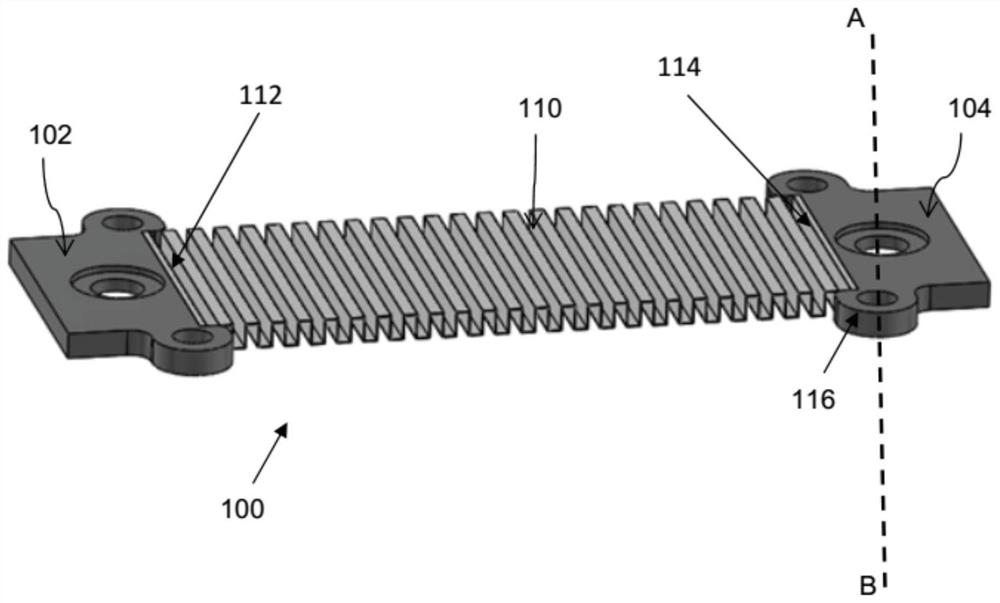

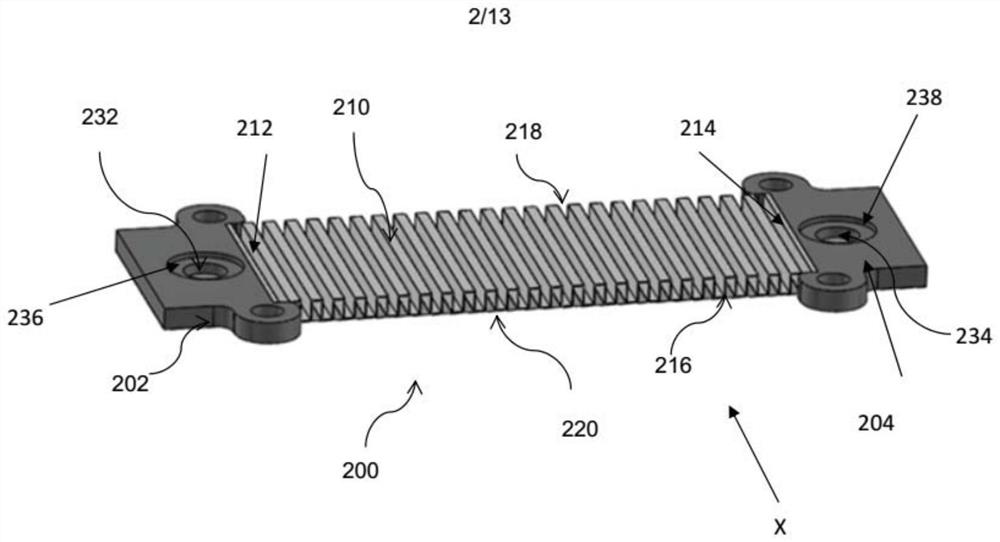

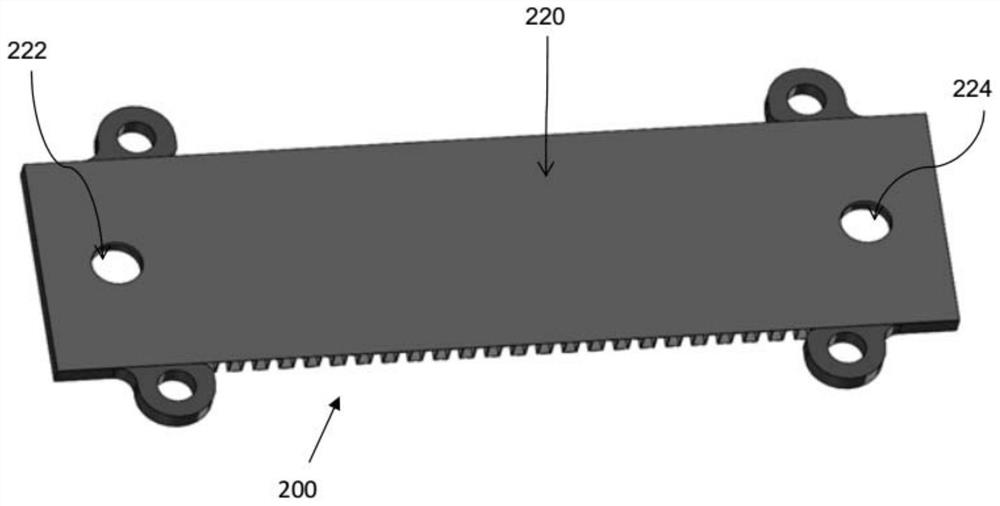

[0050] figure 1 is a front view of a plate member for a battery stack in an exemplary embodiment. In the exemplary embodiment, plate member 100 includes two alignment features 102 and 104 and channel sheet 110 . In an exemplary embodiment, the channel sheet 110 includes at least one peak and one valley in the body of the sheet and is in the form of a corrugated sheet 110 . The corrugated sheet 110 is coupled to a first alignment feature 102 at a first end or edge 112 of the corrugated sheet 110 and to a second alignment feature 104 at a second end or edge 114 of the corrugated sheet 110 . Accordingly, the corrugated sheet 110 is disposed betwe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com