Hydraulic inserted pin lifting device

A lifting device and hydraulic technology, applied in the field of marine engineering equipment, can solve the problem that the self-elevating offshore platform cannot be continuously raised and lowered

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

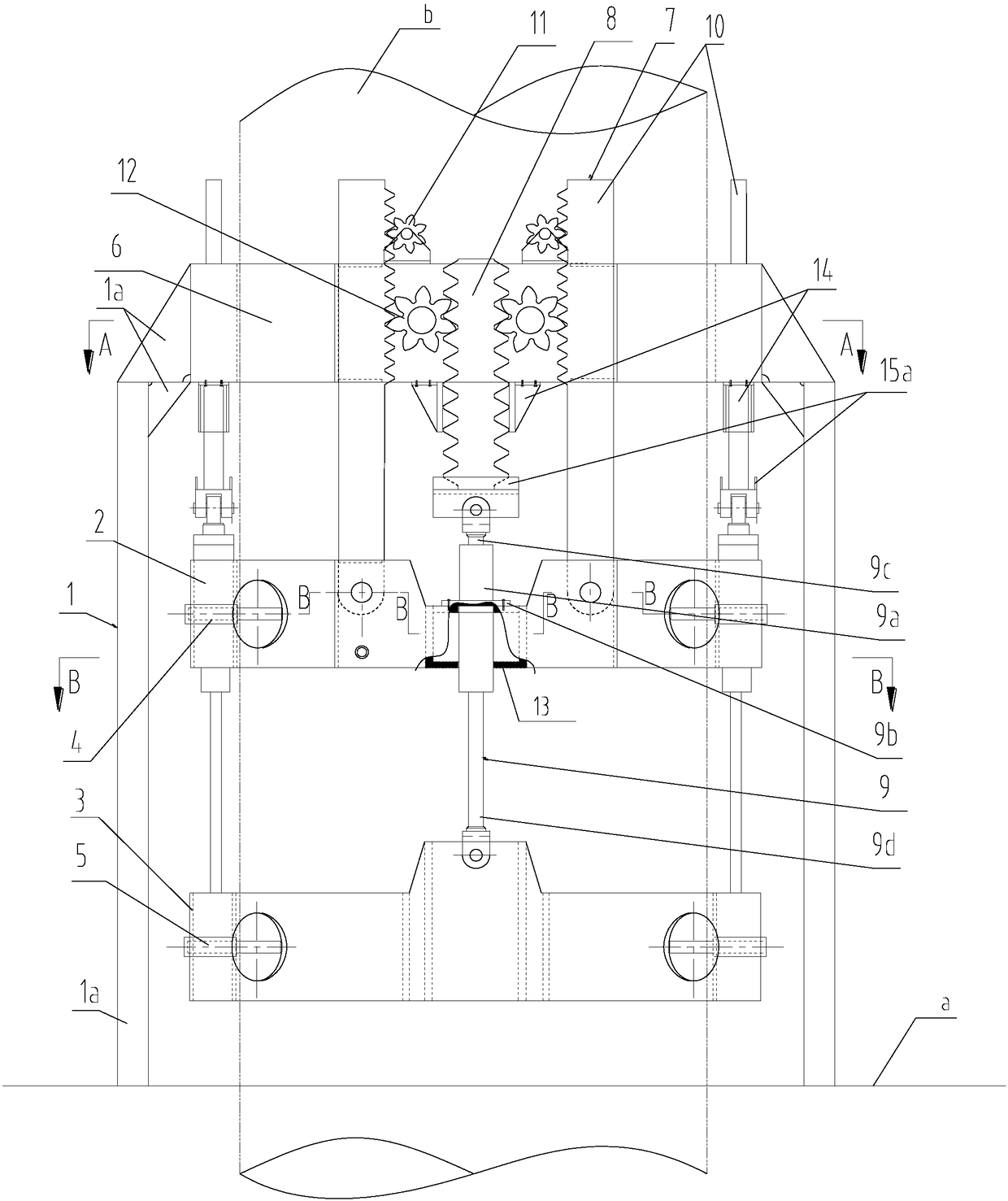

[0023] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

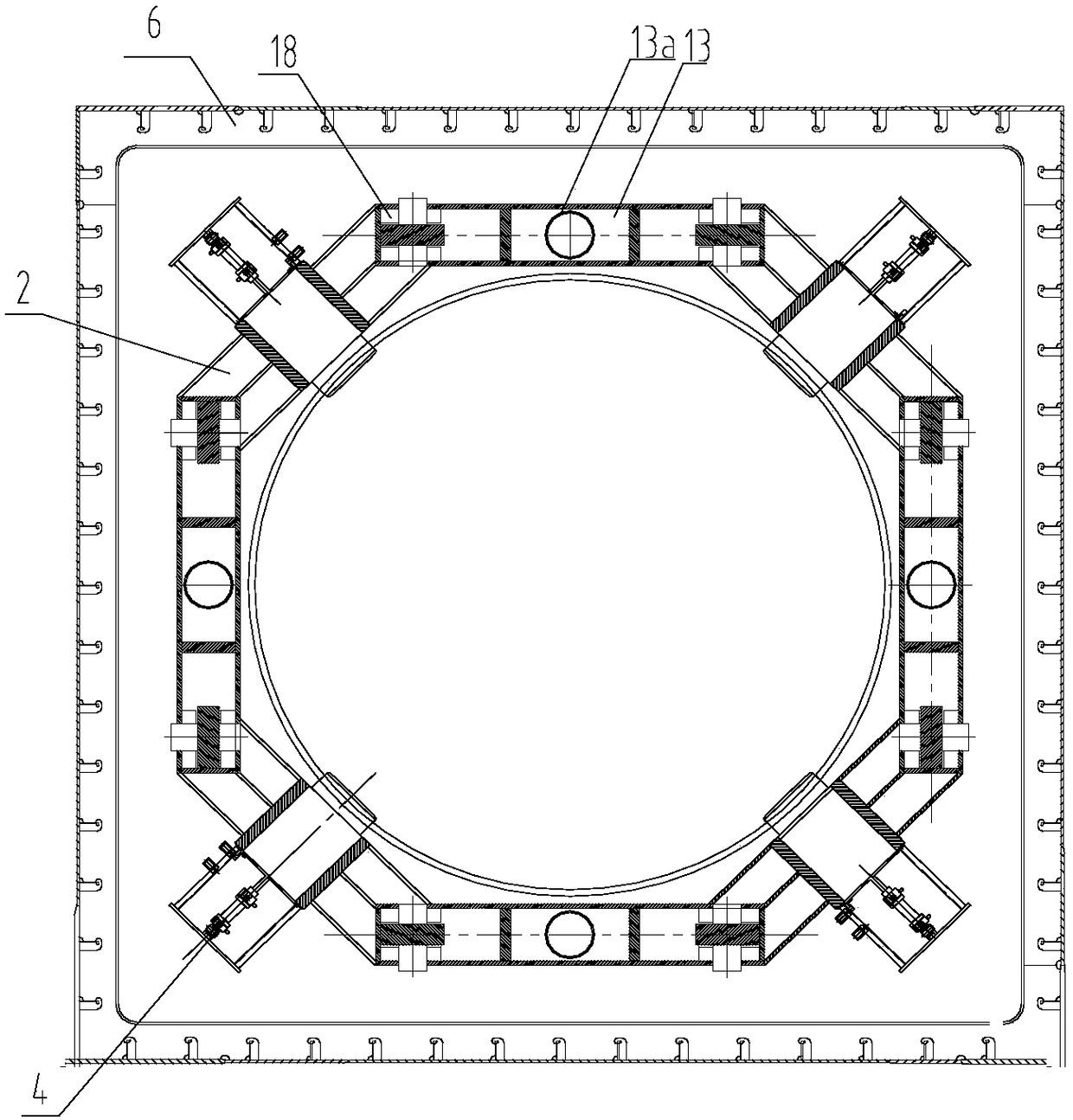

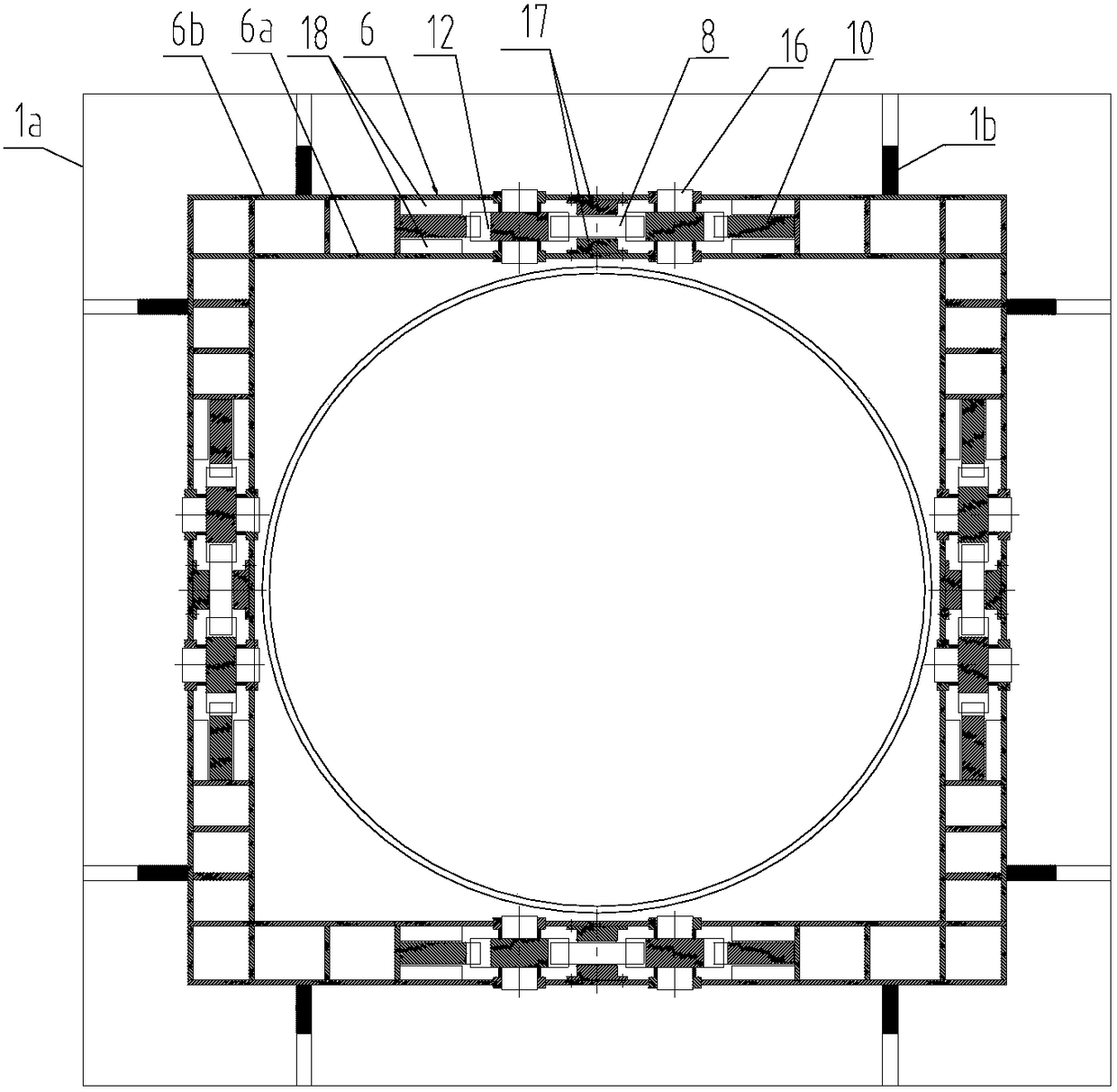

[0024] The embodiment of the present invention provides a hydraulic bolt lifting device, the hydraulic bolt lifting device includes: a pile frame 1, a first ring beam 2, a second ring beam 3, a first ring beam bolt assembly 4 and a second ring beam bolt Component 5,. The first ring beam latch assembly 4 is installed on the first ring beam 2 , and the second ring beam latch assembly 5 is installed on the second ring beam 3 .

[0025] The pile-fixing frame 1 includes a pile-fixing frame ring beam 6, the pile-fixing frame ring beam 6, the first ring beam 2 and the second ring beam 3 are coaxially and sequentially arranged at intervals, and the hydraulic bolt lifting device also includes at least two lifting devices 7, At least two liftin...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap