A small catheter tip machine

A small catheter and pointed technology, applied in the field of small catheter pointed machine, can solve problems such as a large number of debris and inconvenience, and achieve the effect of simplified steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

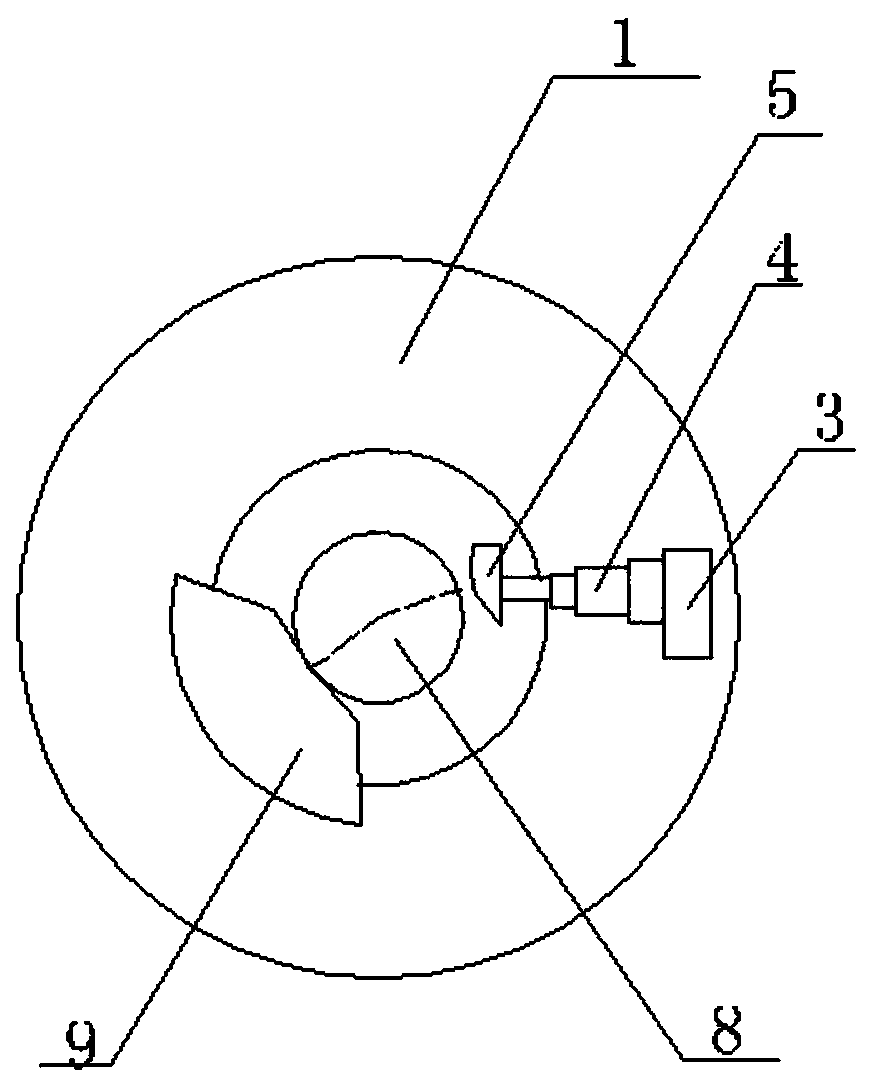

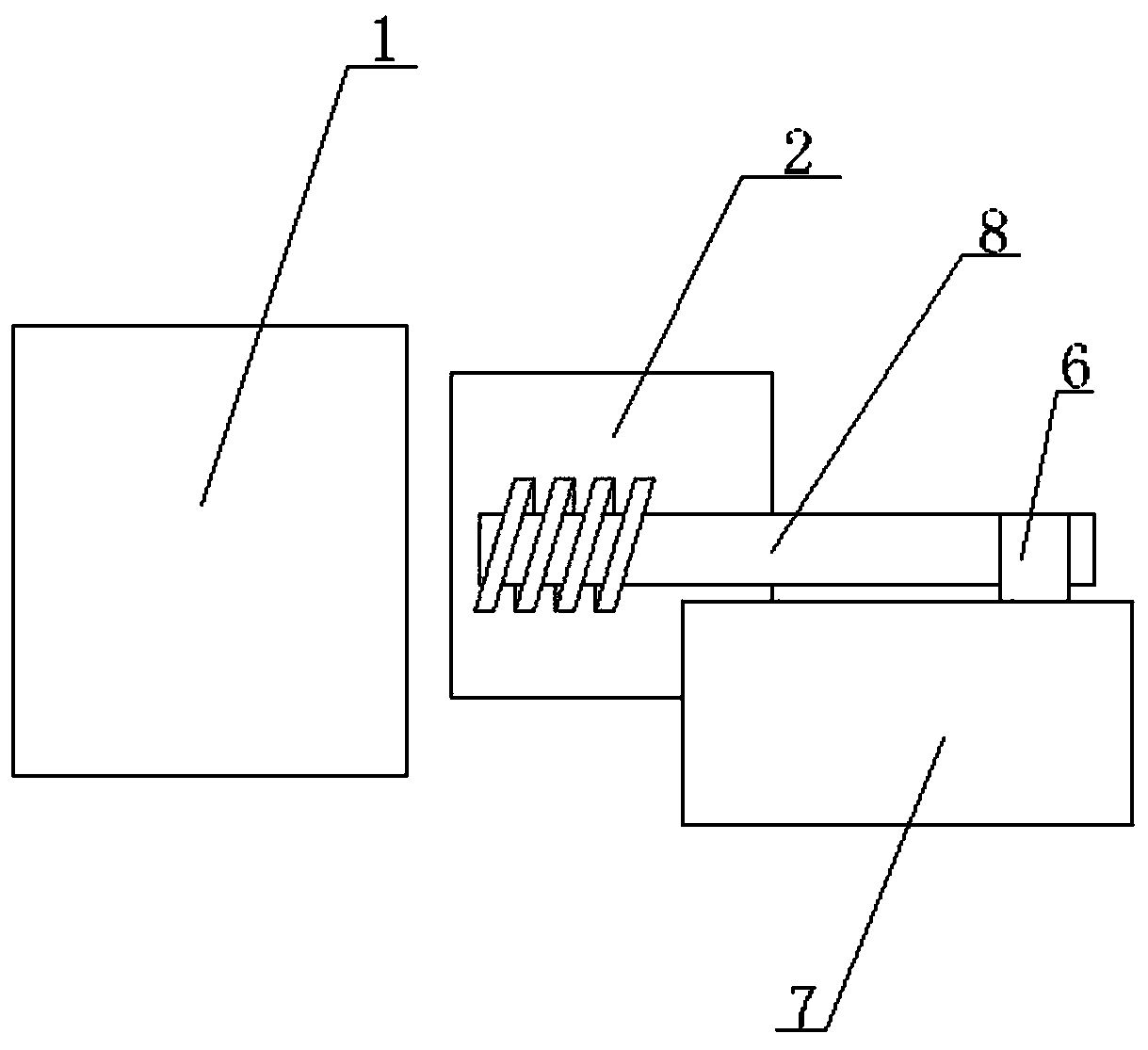

[0012] A small catheter pointing machine, including a fixed plate 1, a lateral adjustment platform for controlling the lateral movement of the catheter 8, a heater 2 located between the lateral adjustment platform and the fixed plate 1, and the heater 2 is used for heating and melting the catheter 8, the middle of the fixed disk 1 is provided with a perforation corresponding to the conduit 8, and the fixed ring is provided with an eccentrically arranged knocking assembly, which includes sequentially connecting the drive pump 3 and the telescopic rod 4 and arc-shaped hammer head 5, the drive pump 3 controls the arc-shaped hammer head 5 to strike the side of the conduit 8 through the telescopic rod 4, and after the knock, the conduit 8 moves to the direction of the eccentric force under the action of the eccentric force One side rotates, thereby makes the...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap