Double-press roller automatic laying-and-winding shaping device used for ridged revolving body

A technology of forming device and revolving body is applied in the field of double-roller automatic laying and wrapping forming device. The effect of high laying efficiency and improving the efficiency of automatic laying and forming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with specific embodiments.

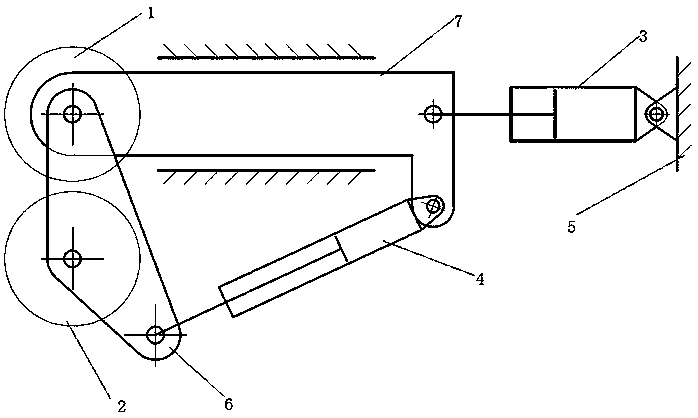

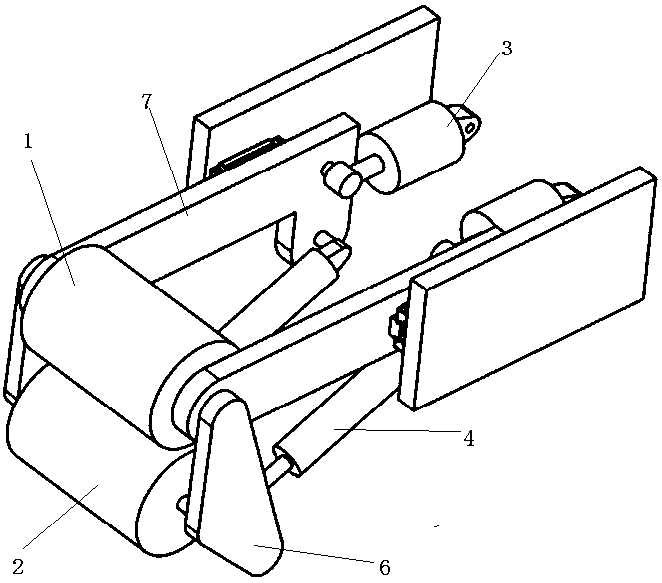

[0022] The embodiment of the present invention provides a double-pressure roller automatic wrapping and forming device for a rotary body with ribs, such as figure 1 and figure 2 As shown, it includes: main pressure roller 1, auxiliary pressure roller 2, main pressure roller cylinder 3, auxiliary pressure roller cylinder 4, fixed surface 5, auxiliary pressure roller linkage plate 6, and main pressure roller linkage plate 7.

[0023] Both ends of the central axis of the main pressure roller 1 are connected to a set of main pressure roller linkage plates 7 , and both ends of the central axis of the auxiliary pressure roller 2 are connected to a set of auxiliary pressure roller linkage plates 6 . The main pressure roller linkage plate 7 is also connecte...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap