Research Method of Solidification Process Information on Free Surface of Metal Melt

A technology of metal melt and process information, applied in the direction of applying stable tension/pressure to test material strength, instruments, and using wave/particle radiation for material analysis, etc., can solve the problem of lack, surface solidification structure varies greatly, and laws are difficult to find, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Embodiment 1 The research method of free surface solidification structure of titanium alloy melt

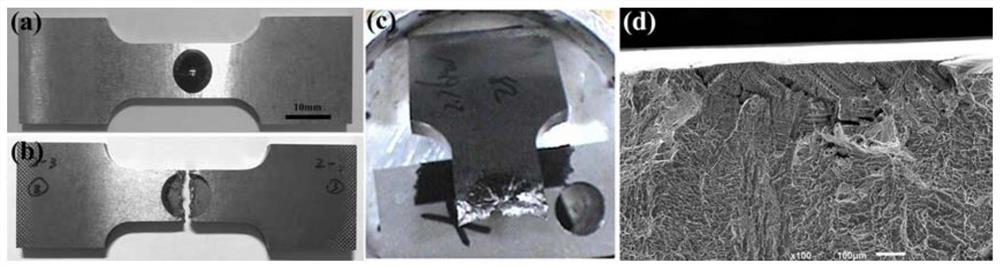

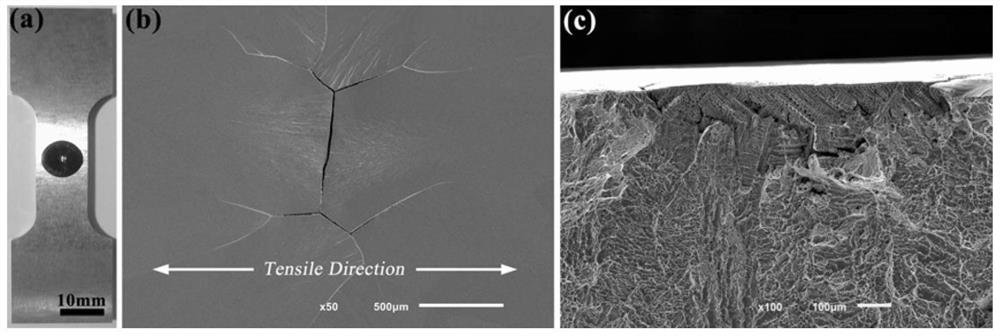

[0031] Such as figure 1 As shown, the method mainly includes the following steps, designing a tensile sample (a); point-shaped laser surface remelting (b); fast breaking of the sample (c); fracture thermal crack structure observation (d) four parts, specifically The research steps are as follows:

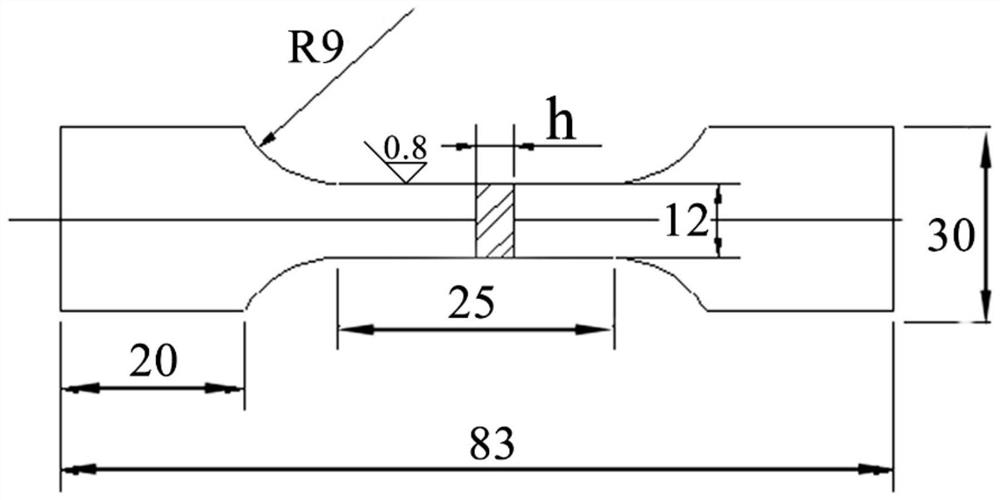

[0032] Design the tensile test specimen. According to the conventional built-in parameters of the high-power laser, universal mechanical testing machine and scanning electron microscope used in the research, the dimensions of the plate-shaped tensile specimen specially used for the observation of the surface solidification structure are designed as follows: figure 2 shown. The surface of the sample is polished, and the thickness h of the sample is determined according to the following formula: h=F / s·k·σ.

[0033] Among them, F is the tensile force of the universal testing m...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap