Tyre

A tire and carcass technology, applied in heavy tires, tire parts, tire edges, etc., can solve the problems of fragile durability performance and quality, complex manufacturing process of semi-finished plies, and achieve the effect of reducing weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

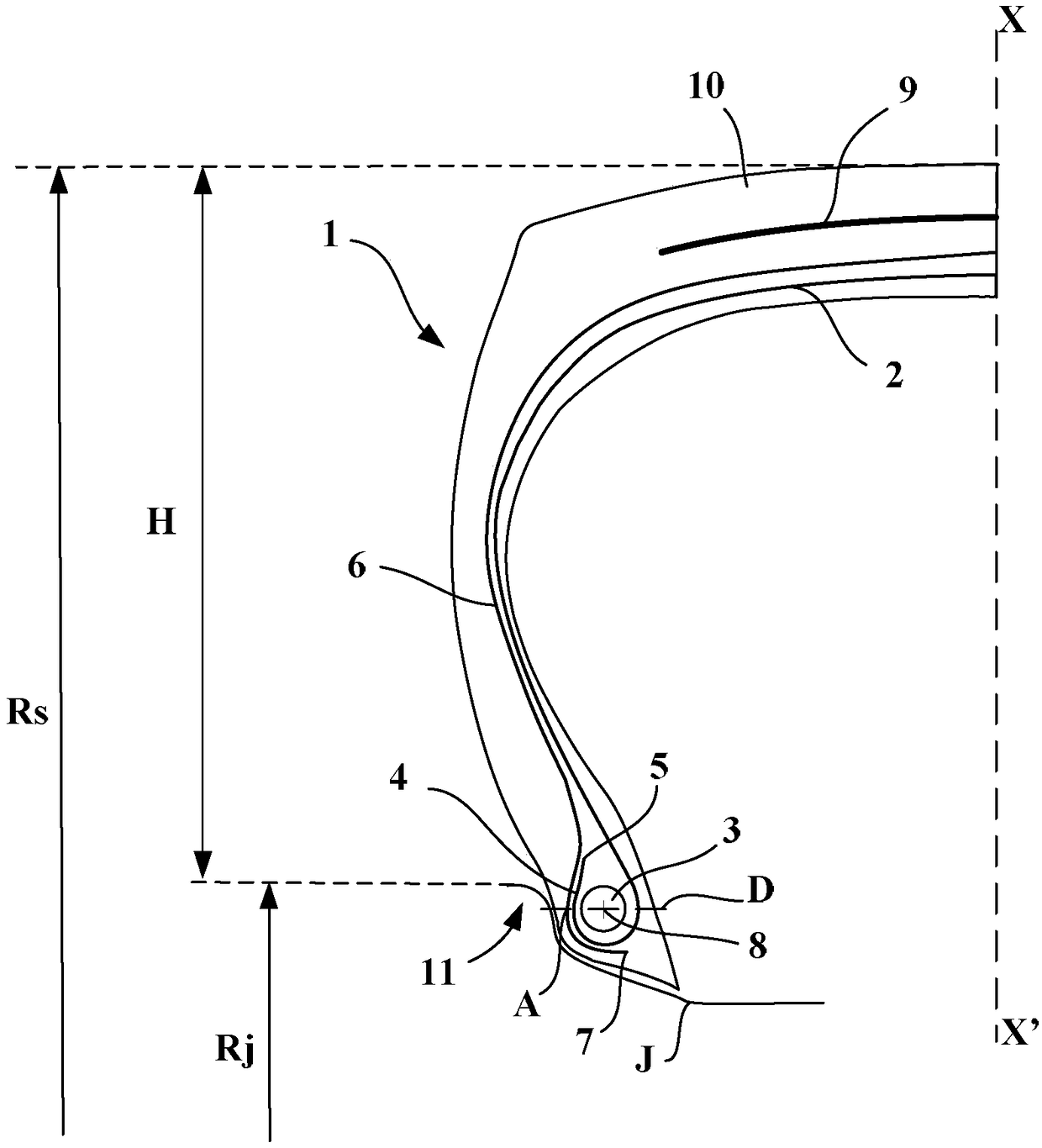

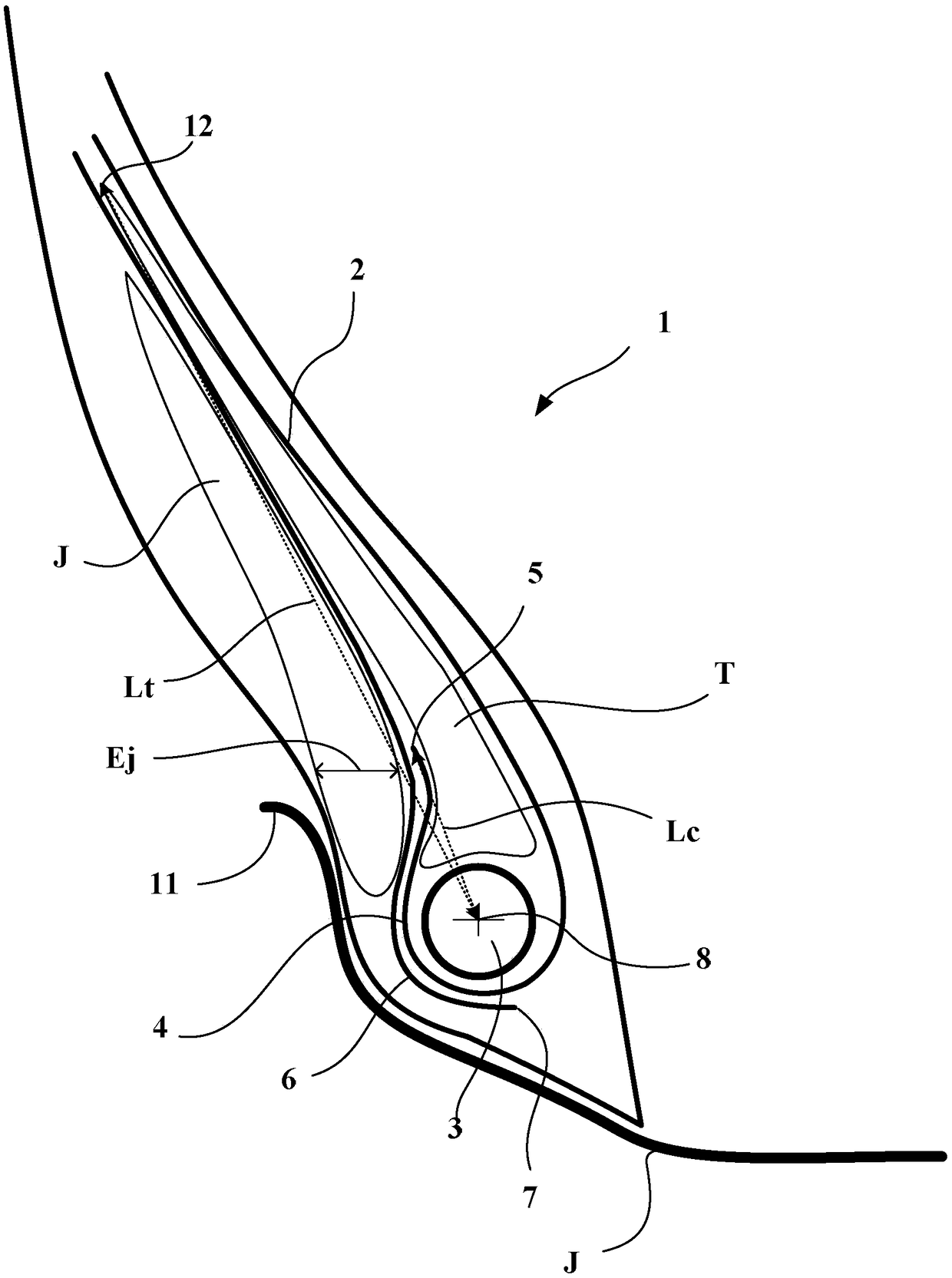

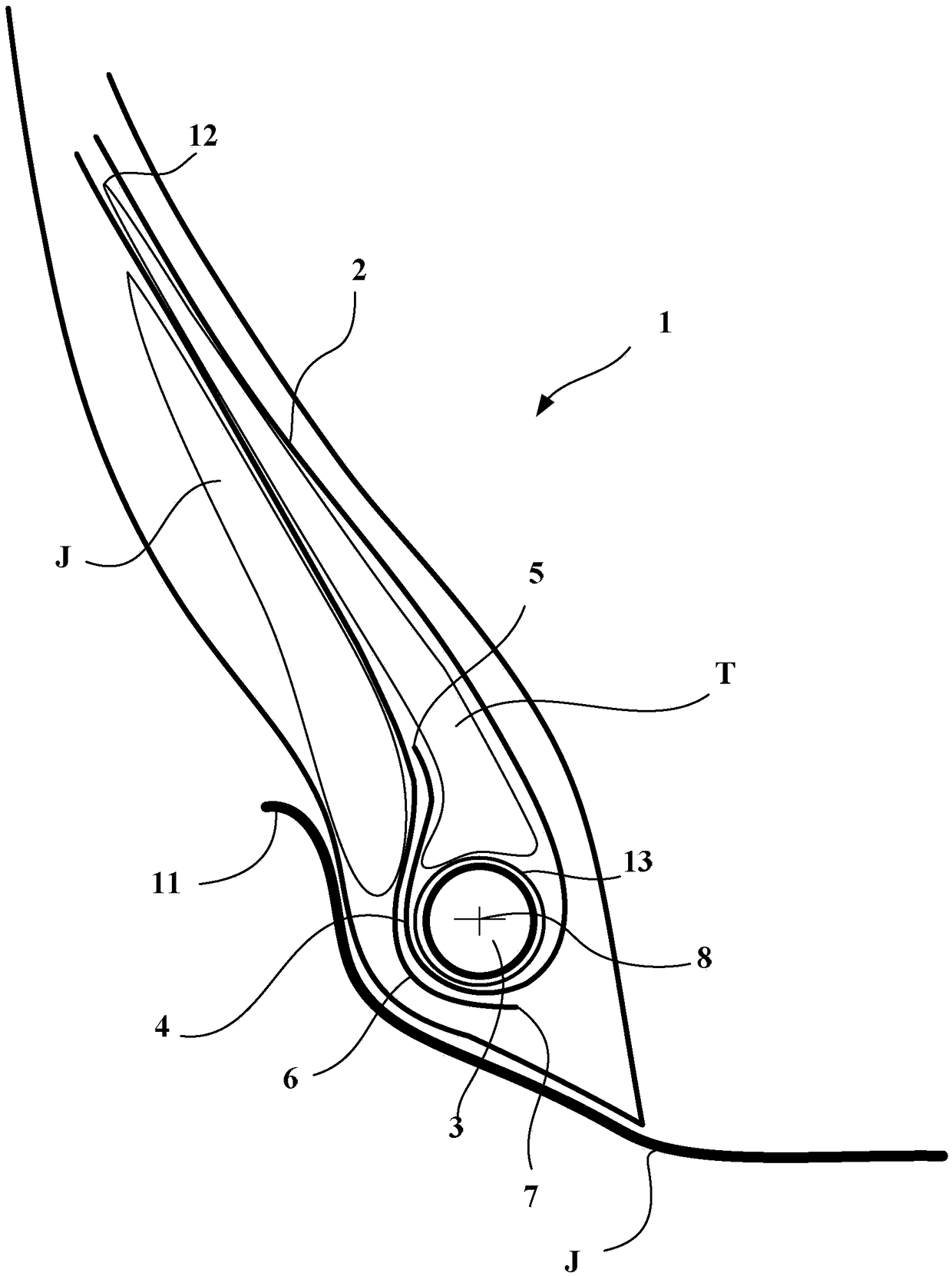

[0082] figure 1 Only a half-view of a tire is shown, which extends in a symmetrical manner with respect to an axis XX', which represents the circumferential mid-plane or equatorial plane of the tire.

[0083] figure 1 A schematic cross-sectional depiction of a small truck type tire 1 of size 215 / 75R17.5 is shown. Should figure 1 A carcass reinforcement comprising a first carcass reinforcement ply 2 wound around a bead core 3 forming a turn-up 4 with an end 5 is shown. Also shown is a second carcass reinforcement ply 6 , the ends 7 of which are radially inside and axially inside the geometric center 8 of the bead core 3 .

[0084] The beads were braided beads with a diameter equal to 9.2 mm.

[0085] Present radially on the outside of the carcass reinforcement is a crown reinforcement 9 , which is in turn radially covered with a tread 10 .

[0086] The carcass reinforcement plies 2 and 6 consist of reinforcing elements between two calendered plies made of a rubber-like ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap