Screw chiller and its control method and system

A technology of water chillers and control methods, applied in the direction of refrigerators, refrigeration components, compressors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

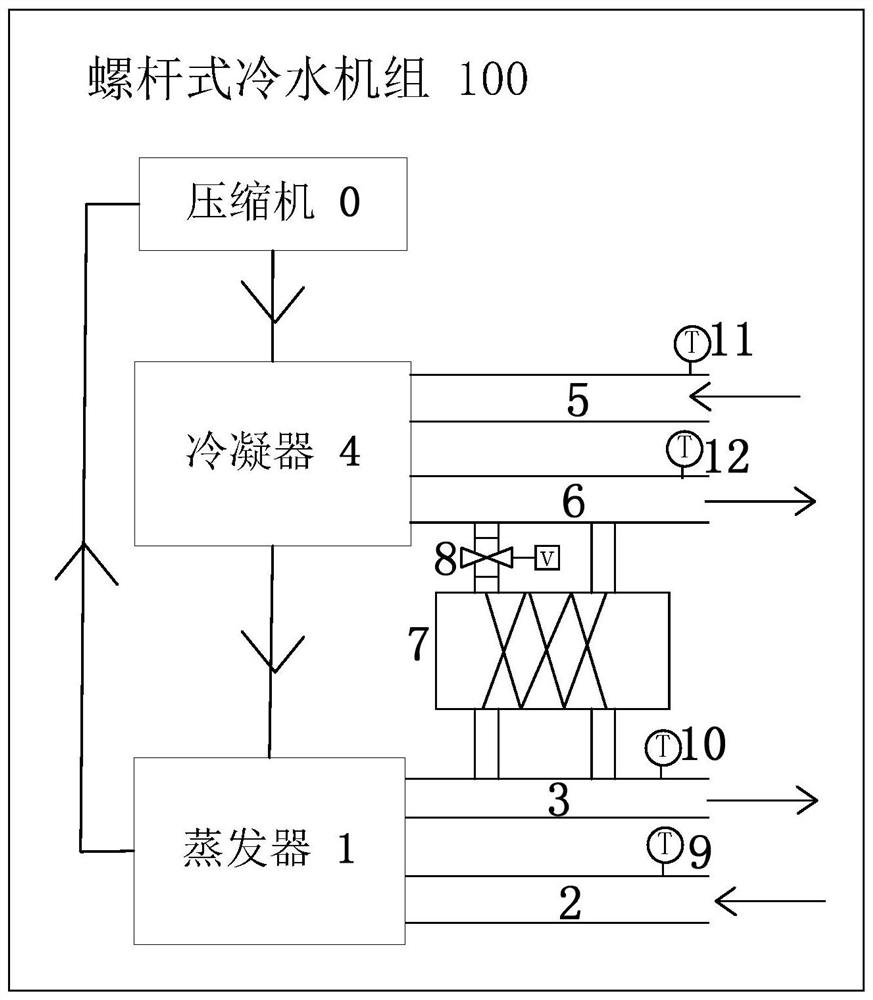

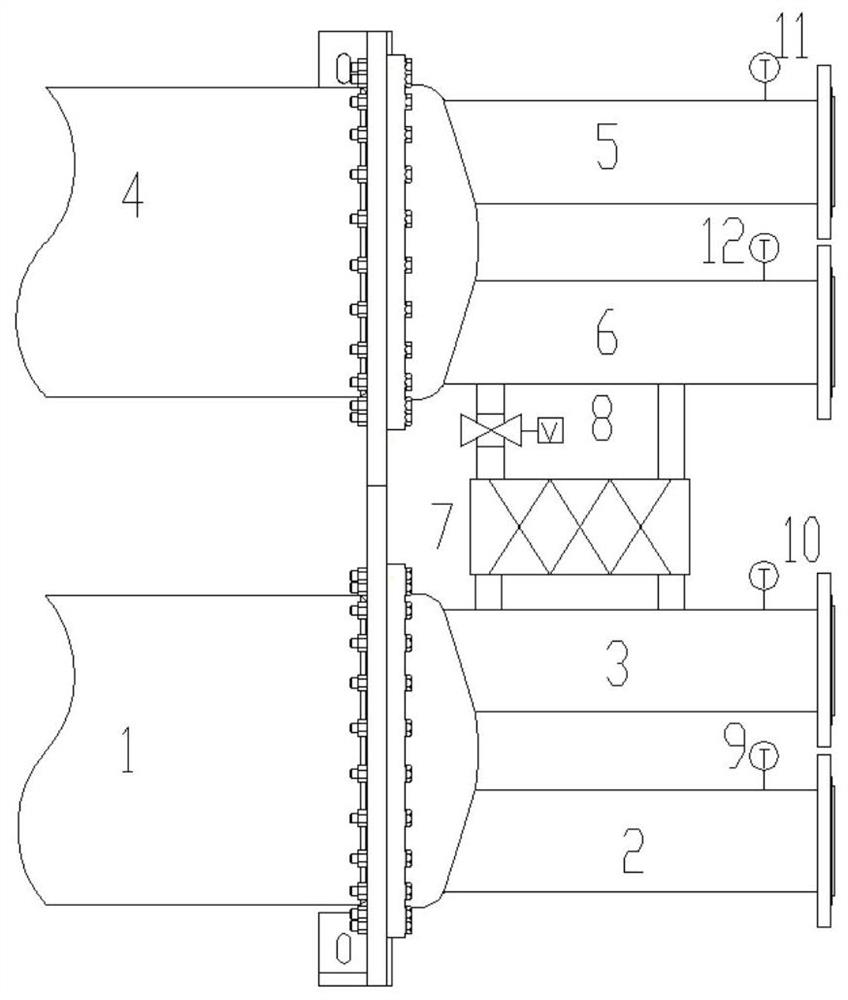

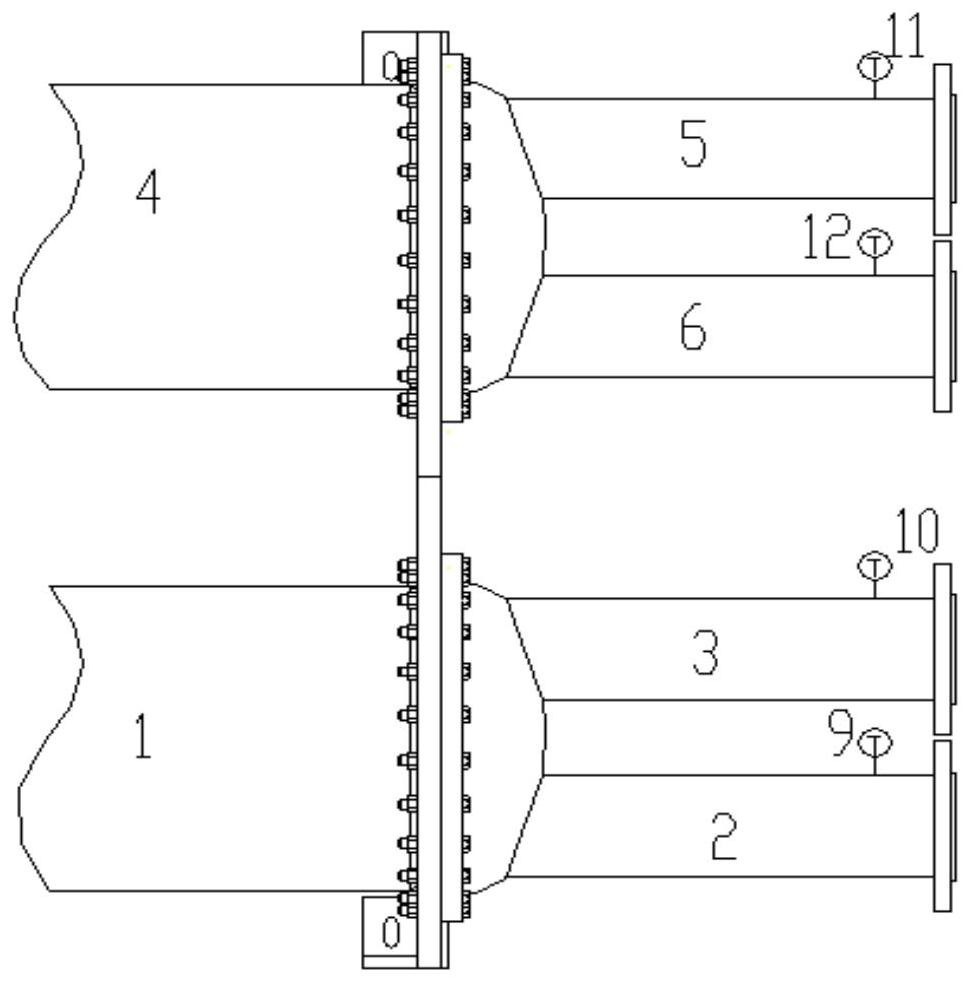

[0027] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with the embodiments and accompanying drawings. Here, the exemplary embodiments and descriptions of the present invention are used to explain the present invention, but not to limit the present invention.

[0028] Considering that the existing screw chillers cannot realize the stepless adjustment of the output load of the chiller in a large range, or cannot realize the zero load output without shutting down. Aiming at the root cause of the above-mentioned technical problems, the present invention considers that a screw chiller can adopt a zero-load output and non-stop operation mode, and use the screw chiller to freeze the incoming water through the heat exchanger to adjust the temperature of the chilled outlet water. When the temperature reaches the set value, even if the output load of the compr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com