Slidable lifting auxiliary device

A technology of auxiliary devices and slides, which is applied in the direction of lifting devices, lift frames, etc., can solve the problems of inability to adjust the relative position, difficulty in lifting large switch mechanisms, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

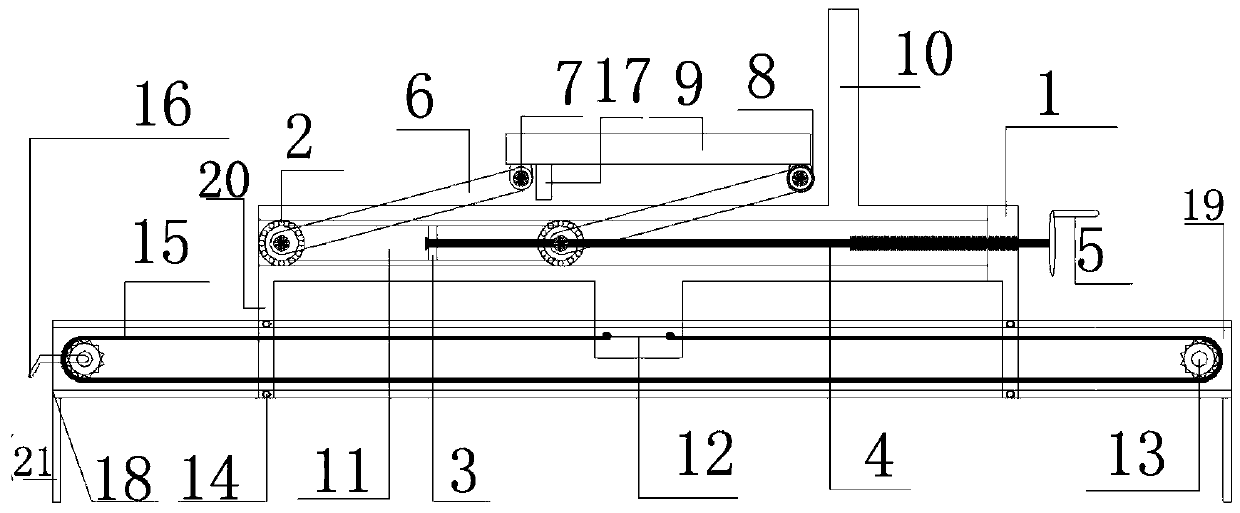

[0030] A slideable lifting aid such as figure 1 As shown, it includes frame body 1, rotating bearing 2, intermediate connecting plate 3, screw rod 4, transmission rod 6, hinge bolt 7, plane bearing 8, supporting platform 9, baffle plate 10, side connecting plate 11, supporting platform 19 ;

[0031] The baffle plate 10 is connected to the top of the frame body 1;

[0032] The inside of the frame body 1 is provided with a concave slideway 18, and at the same time, both sides of the frame body 1 are provided with side connecting plates 11, and the side connecting plates 11 are connected through the middle connecting plate 3. All are provided with a rotating bearing 2, and the rotating bearing 2 is fitted and connected with the concave-shaped slideway 18, and the rotating bearing 2 is used to convert plane friction into sliding friction and reduce friction in the lifting process.

[0033] The side connecting plates 11 are connected by the middle connecting plate 3, so that both...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com