A high-frequency annealing tool and method for pins

A high-frequency annealing and tooling technology, applied in the field of heat treatment, can solve the problems of low production efficiency and difficult to manufacture, and achieve the effect of easy operation, simple structure, and ensuring the annealing requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical solution of the present invention is further described below, but the scope of protection is not limited to the description.

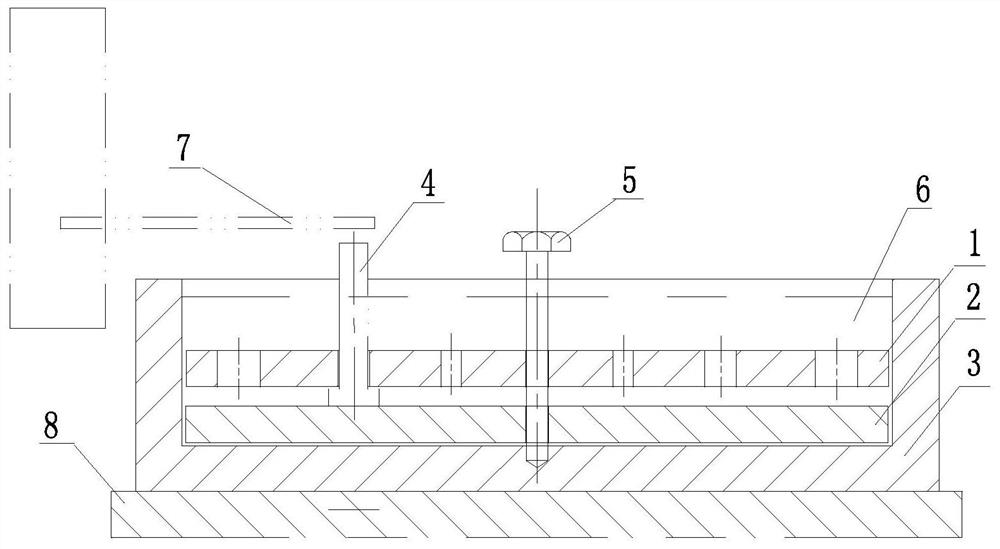

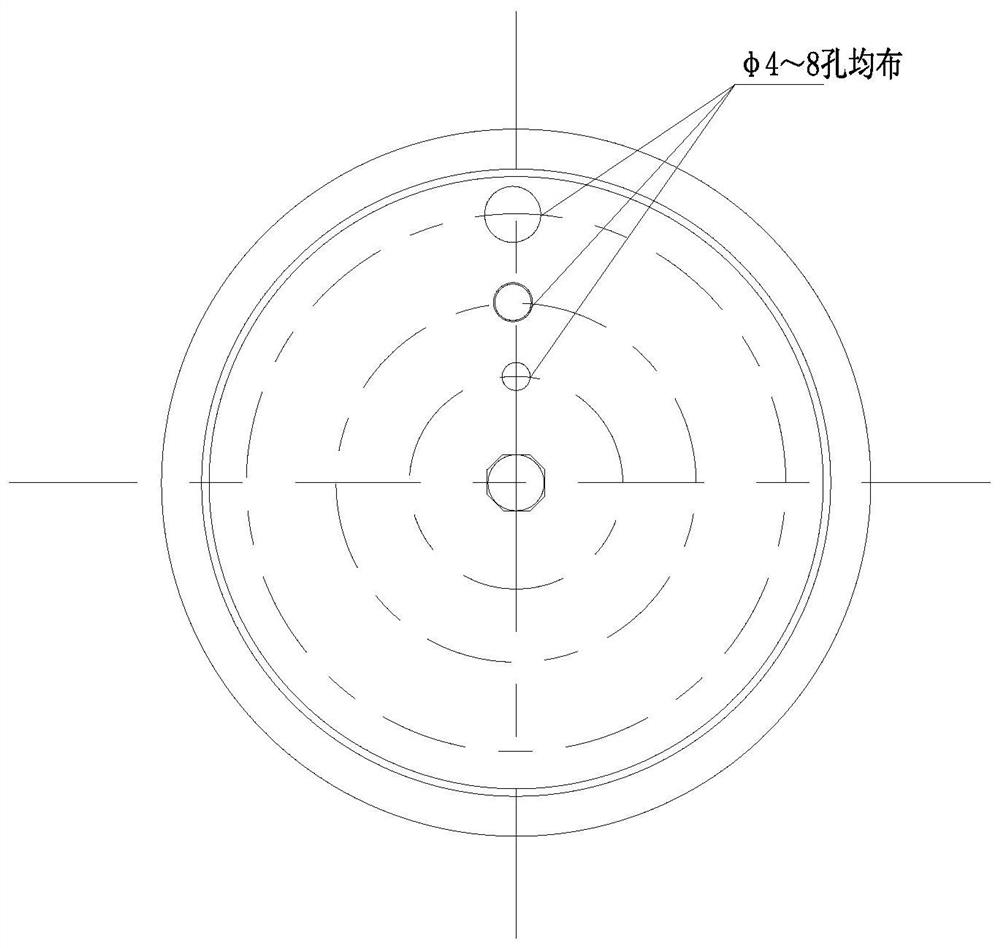

[0026] Such as Figure 1-2 As shown, a high-frequency annealing tooling for pins includes a pressing plate, a tooling bottom plate, a tooling cylinder, a high-frequency induction coil, and an adjustable platform, wherein the tooling cylinder is fixed on the adjustable platform; The mounting hole corresponds to the size of the pin. The pressure plate is placed on the bottom plate of the tooling and placed in the tooling tube together. The high-frequency induction coil is set on the upper part of the tooling tube. The bottom of the pressing plate passes through the pressing plate in reverse, and the tooling bottom plate is pushed against the head of the pin, and together with the pressing plate, the pin is fixed in the tooling barrel.

[0027] Further, the bottom of the tooling tube is closed, and water is filled inside, and when th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com