Air return box for pre-oxidation furnace and pre-oxidation furnace

The technology of a pre-oxidation furnace and a return air box is applied in the field of oxidation furnace, which can solve the problems affecting the pre-oxidation treatment of fibers, and achieve the effect of sufficient return air and good effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

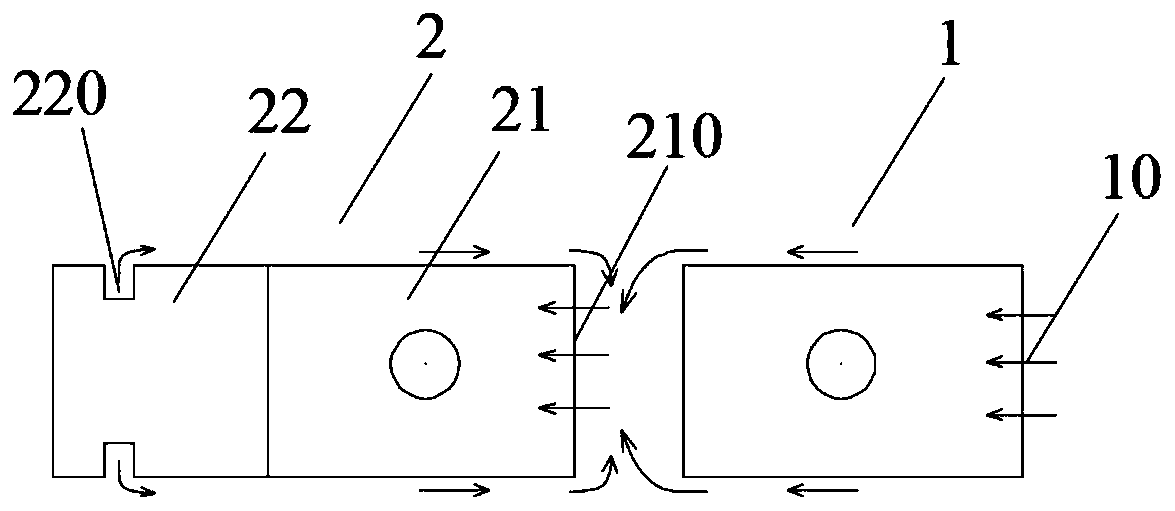

[0044] Such as figure 1 As shown, the return air box for the pre-oxidation furnace of this embodiment is a split design, including a first box 1 and a second box 2 arranged in sequence along the return air direction of the pre-oxidation furnace, the first box 1 and the second box The two boxes 2 are distributed at a preset distance, and the preset distance between the first box 1 and the second box 2 is greater than 60 mm.

[0045] Wherein, the first box body 1 has a first air return port 10 on the side facing the return air direction, which is used to absorb most of the wind in the furnace blowing towards the furnace end, so as to return air through the first box body 1 into the return air duct.

[0046] The second box body 2 includes a return air cavity 21 and a fresh air cavity 22 distributed in sequence along the return air direction of the pre-oxidation furnace. The return air cavity 21 has a second return air port 210 on the side facing the return air direction. 22 has ...

Embodiment 2

[0057] The difference between the air return box for the pre-oxidation furnace of the present embodiment and the first embodiment is:

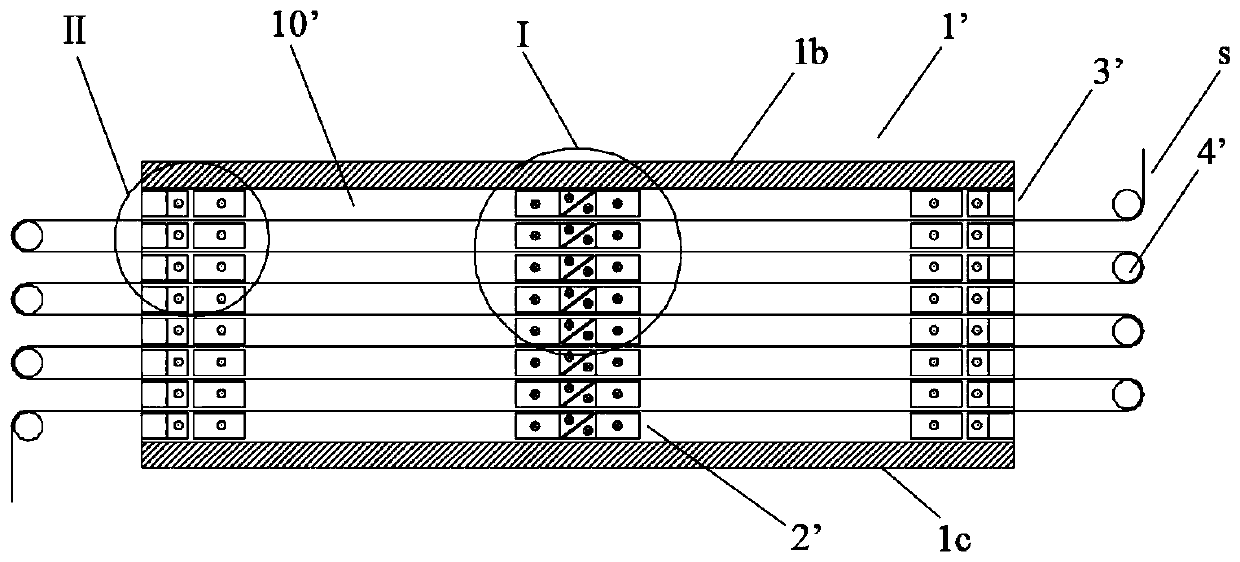

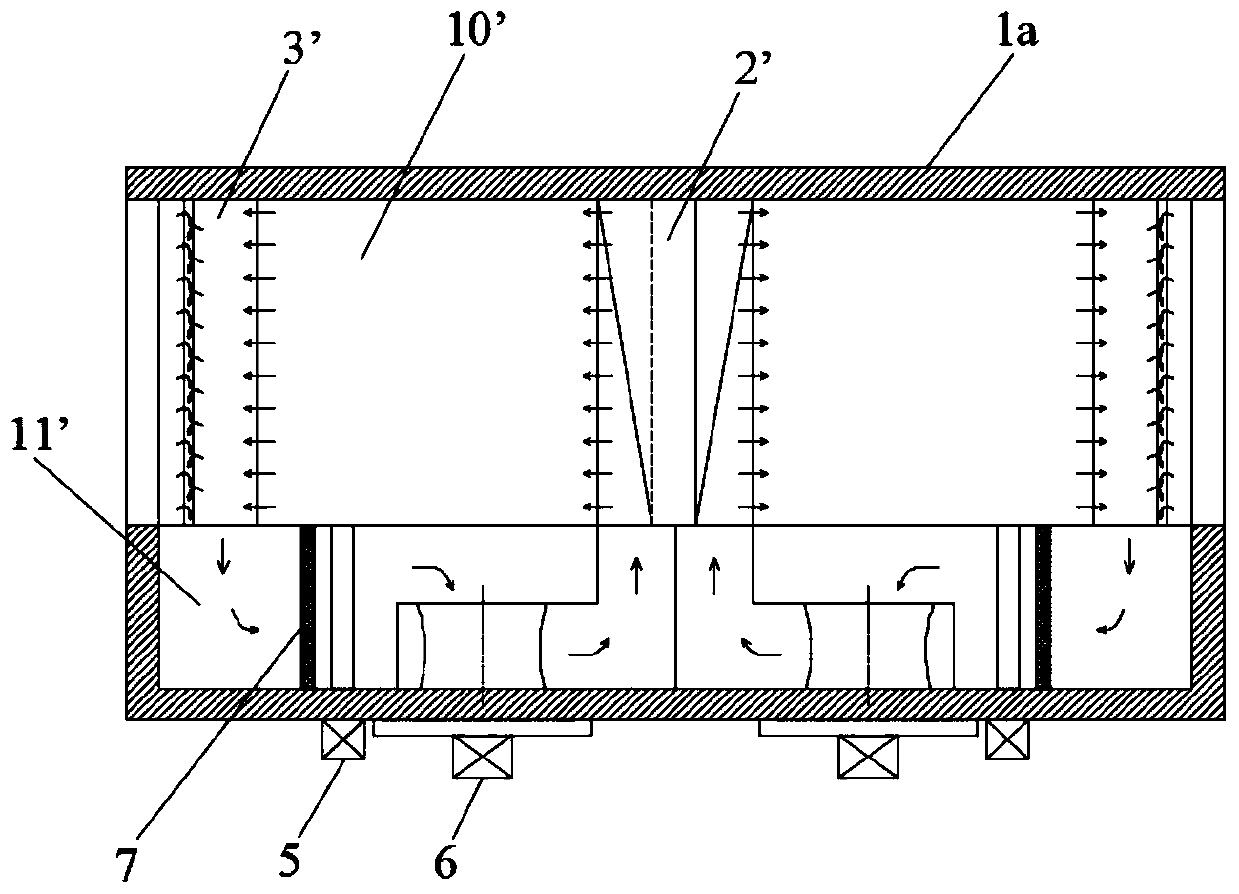

[0058] Such as Figure 9 As shown, the first air return port of the first box body in this embodiment is provided with a first mesh plate 3, and the second air return port of the second box body is provided with a second mesh plate 4. Through the setting of the mesh plate, Improve the uniformity and stability of return air.

[0059] Other structures can refer to Embodiment 1.

[0060] Correspondingly, the differences between the air return box for the pre-oxidation furnace of the present embodiment and the first embodiment are:

[0061] The long-term movement of the pre-oxidation furnace will easily block the first mesh plate 3 and the second mesh plate 4; so it is necessary to clean the first mesh plate and the second mesh plate online, specifically, as Figure 10 and 11 As shown, the furnace body of the present embodiment has a draw-in p...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap