Online pulling and inserting structure of return air inlet mesh plates of pre-oxidation furnace and pre-oxidation furnace

A technology of pre-oxidation furnace and air return port, which is applied to the chemical characteristics of fibers, textiles and papermaking, etc. It can solve the problems of toxic and harmful gas overflow and disadvantages, and achieve the effect of online cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] The online insertion and insertion structure of the mesh plate at the air return port of the pre-oxidation furnace in this embodiment realizes the online cleaning or replacement of the mesh plate.

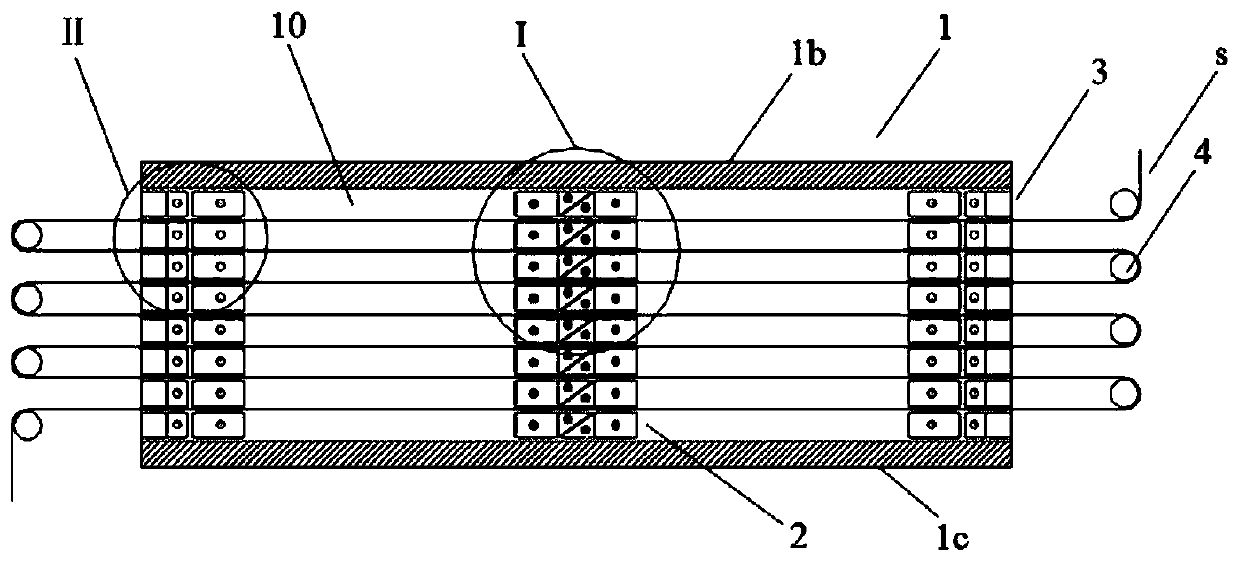

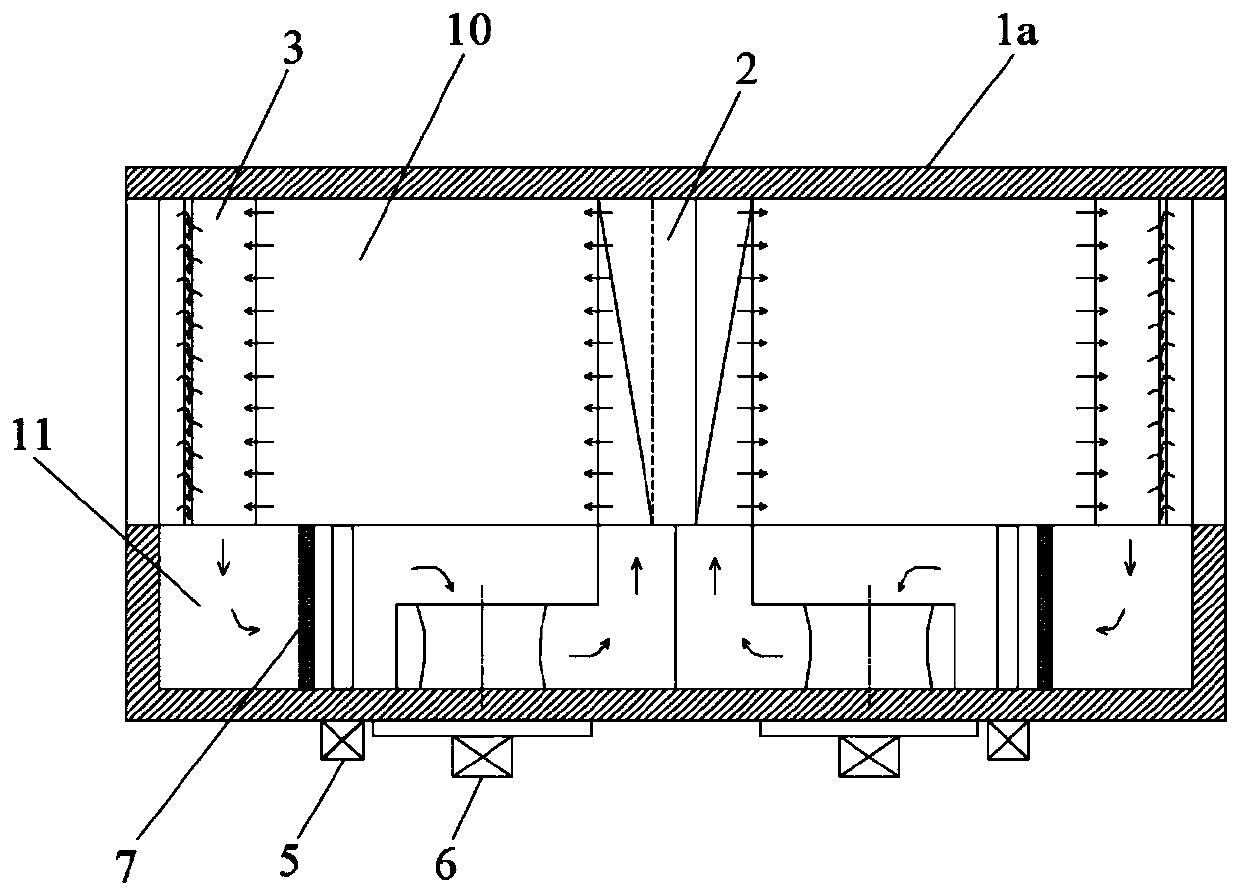

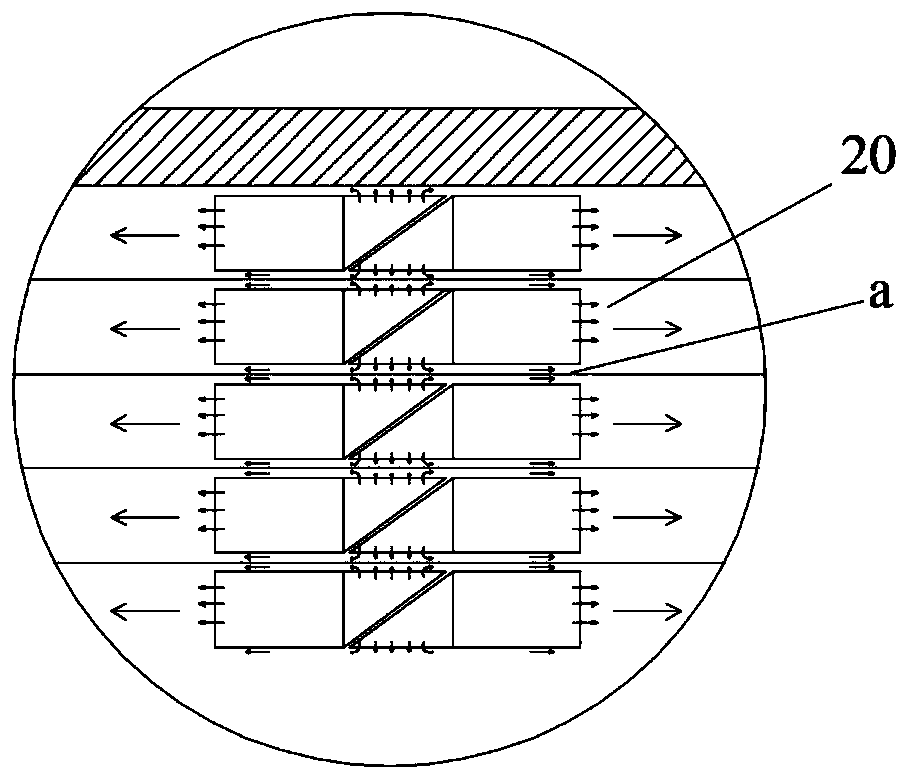

[0054] Specifically, such as Figure 1-9 As shown, the pre-oxidation furnace of this embodiment includes a furnace body 1, an air outlet device 2 and a return air device 3 installed in the furnace body, and guide rollers 4 installed corresponding to the left and right ends of the furnace body 1 .

[0055] Specifically, such as figure 1 and 2 As shown, the furnace body 1 is surrounded by two vertical side walls 1a opposite in the length direction, two vertical end walls opposite in the width direction, a top wall 1b, and a bottom wall 1c. Hollow cuboid structure; the end walls at the left and right ends of the furnace body have seven sets of through-holes arranged at vertical intervals; the furnace body 1 has a wire-running channel 10 distributed along its length, that is, ...

Embodiment 2

[0070] The online extraction and insertion structure of the mesh plate at the air return port of the preoxidation furnace in this embodiment realizes online cleaning or replacement of the mesh plate.

[0071] Specifically, as Figure 14-24 As shown, the pre-oxidation furnace in this embodiment is an end-to-end blowing structure, including a furnace body 1', an air outlet device 2', a first air return device 3' and a second air return device 4' installed in the furnace body. , and also includes guide rollers 5' installed corresponding to the left and right ends of the furnace body 1'.

[0072] like Figure 14 and 15 As shown, the furnace body 1' is surrounded by two vertical side walls 1a' oppositely arranged along the length direction, two vertical end walls oppositely arranged along the width direction, a top wall 1b', a bottom wall 1c' The hollow cuboid structure is formed; the end walls of the left and right ends of the furnace body have seven groups of oppositely arrang...

Embodiment 3

[0086] The difference between the online drawing and insertion structure of the pre-oxidation furnace return air outlet mesh plate of this embodiment and the first embodiment is that:

[0087] All the sealing sleeves are connected to the same suction channel through their respective connecting pipes, so that multiple suction channels are not required to meet the requirements of different application occasions.

[0088] The pre-oxidation furnace of this embodiment includes the online drawing and insertion structure of the mesh plate of the return air outlet of the pre-oxidation furnace of this embodiment, and the pre-oxidation furnace is used for manufacturing carbon fibers.

[0089] Other structures can refer to Embodiment 1.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap