Automatic setting and optimizing method for working parameters of automatic quantitative packing scale

A technology of quantitative packaging and working parameters, which is applied in the direction of packaging, transportation and packaging, and the type of packaged items. It can solve the problems of large human subjective influence, low control accuracy, and difficult setting and adjustment, so as to eliminate complexity factors, The effect of satisfying the trust condition and eliminating the dependence on technical level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

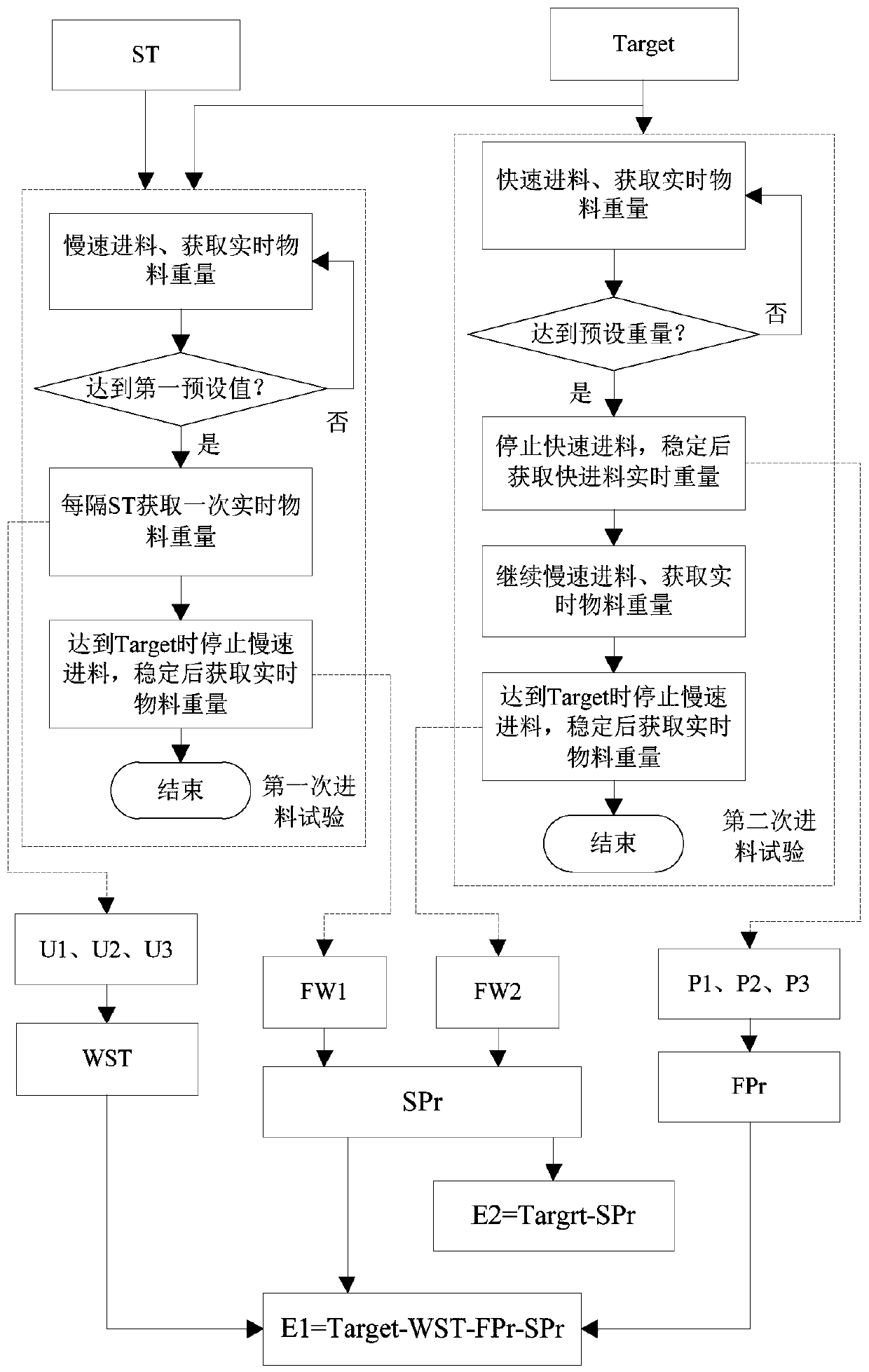

[0035] This application discloses a method for automatic setting and optimization of working parameters of an automatic quantitative packaging scale, please refer to figure 1 As shown in the information flow diagram, the method includes the following steps:

[0036] 1. Obtain the target weight Target that needs to be weighed for each package and the stable duration ST of slow feeding. Wherein, the target weight Target is usually directly input by the user, for example, the target weight Target is set as 25 kg per package. According to the observation of most of the current use scenarios of automatic quantitative packaging scales, as long as the slow feeding process can be ensured to last for a stable time of not less than a certain period of time (that is, the slow feeding stable duration ST) can ensure the accuracy of each package , so th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com