Patents

Literature

35results about How to "Realize automatic tuning" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for self-adjusting control parameters of speed ring of permanent magnet synchronous motor based on fractional orders

ActiveCN103124158ATake full advantage of memory featuresImprove robustnessVector control systemsDynamo-electric converter controlPattern search algorithmPermanent magnet synchronous motor

The invention discloses a method for self-adjusting control parameters of a speed ring of a permanent magnet synchronous motor based on fractional orders. An integer-order proportional integral (PI) controller in an alternating current servo system of the permanent magnet synchronous motor is replaced by a fractional-order PI controller, parameters of the fractional-order PI controller are automatically adjusted, and the alternating current servo system of the permanent magnet synchronous motor can be controlled. The method specifically comprises the following steps of: firstly, acquiring current and speed signals of the alternating current servo system; secondly, identifying a speed ring controlled object model of a permanent magnet synchronous motor servo system according to the acquired signals, and identifying the parameters of the model; and finally, optimally adjusting the control parameters, and thus obtaining optimal control parameters. According to the method, the original integer-order PI controller is replaced by the fractional-order PI controller, and the parameters of the controller are automatically adjusted; the parameters of the controller are optimized by using a pattern search algorithm; and the adjusted parameters of the controller are high in robust, high in anti-disturbance capacity and high in control accuracy.

Owner:HUAZHONG UNIV OF SCI & TECH

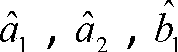

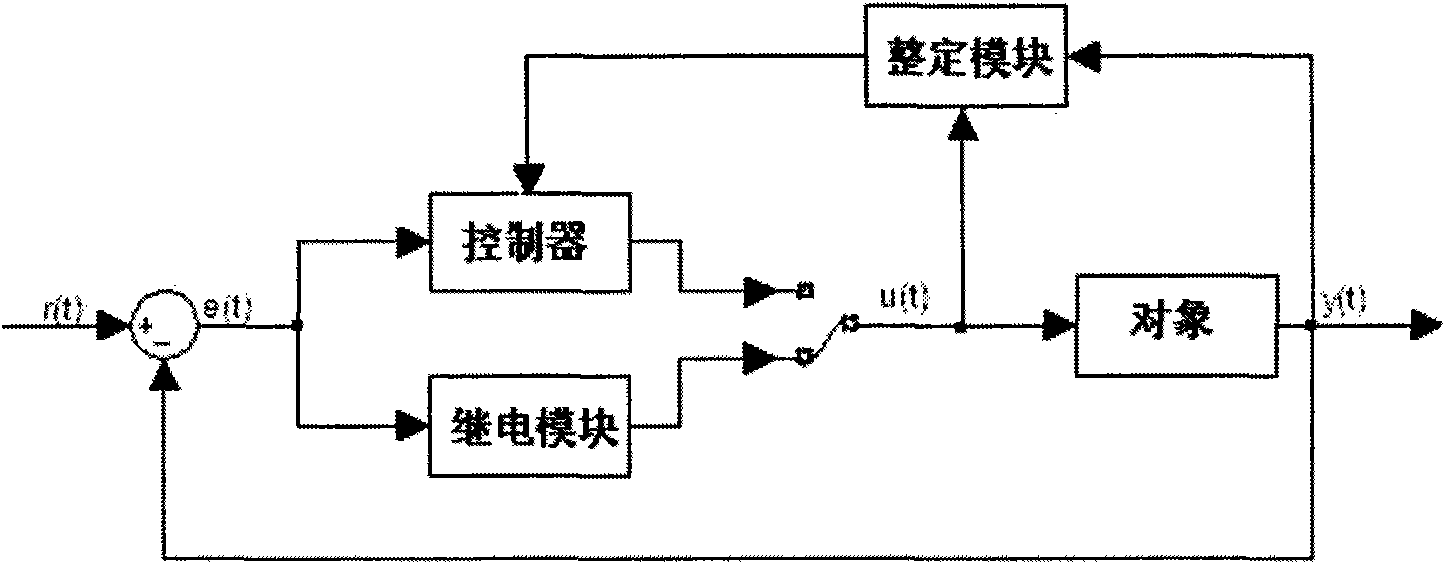

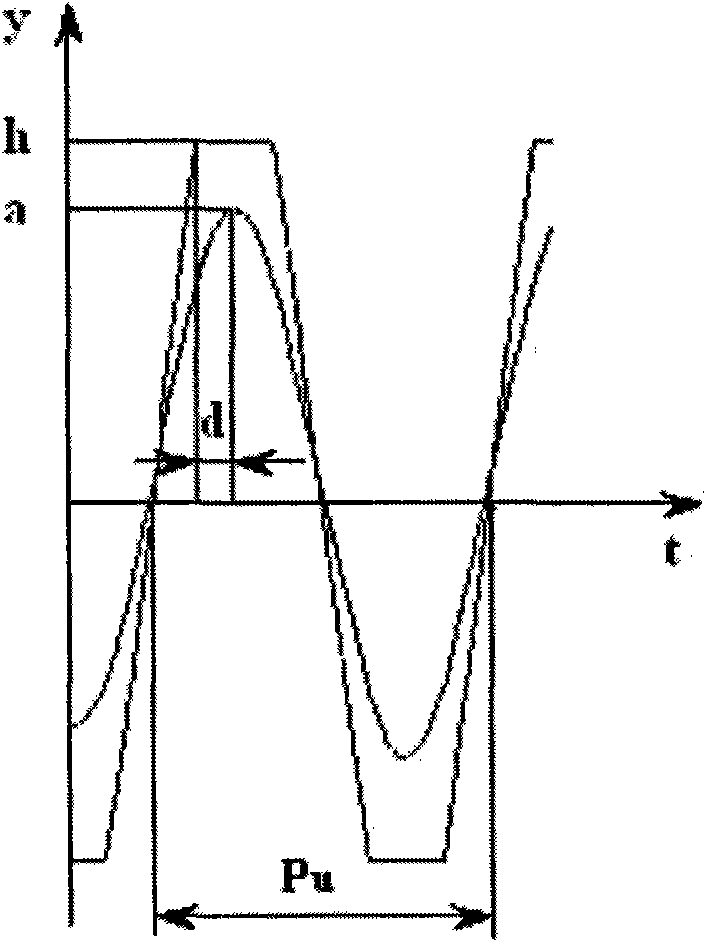

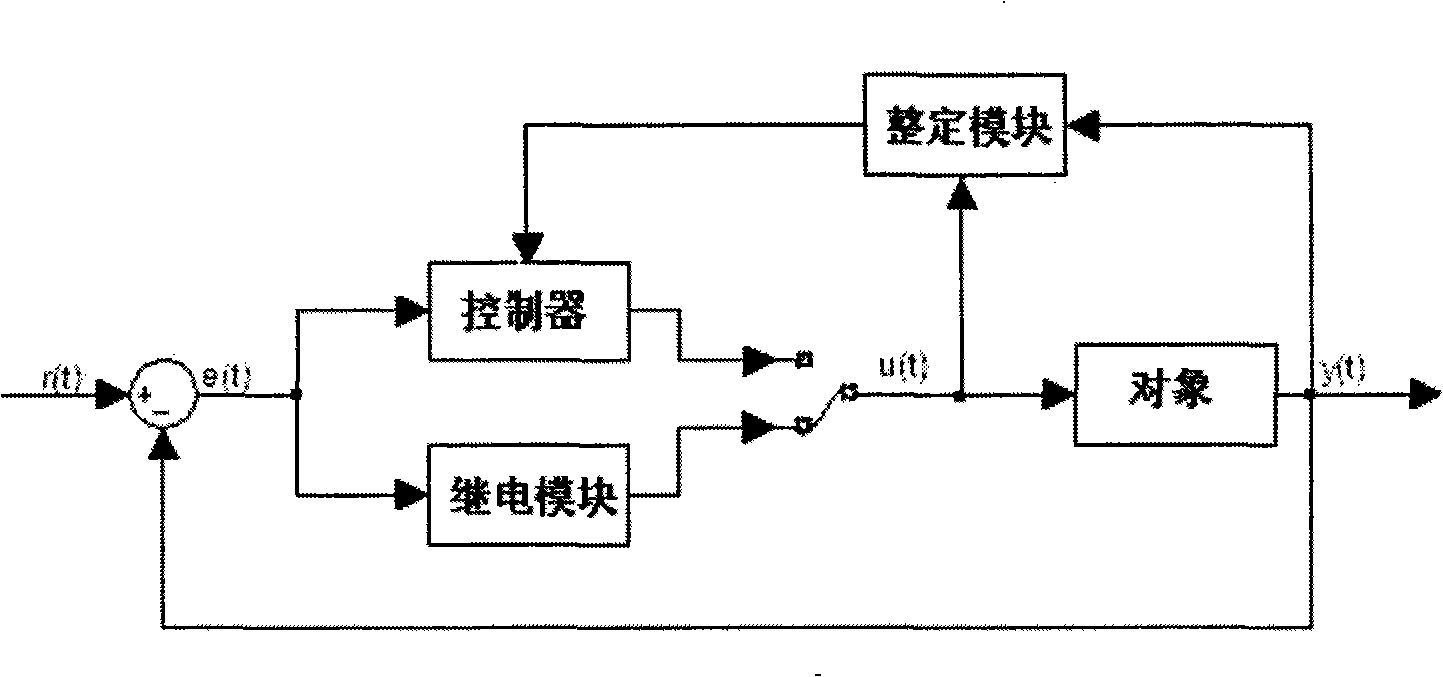

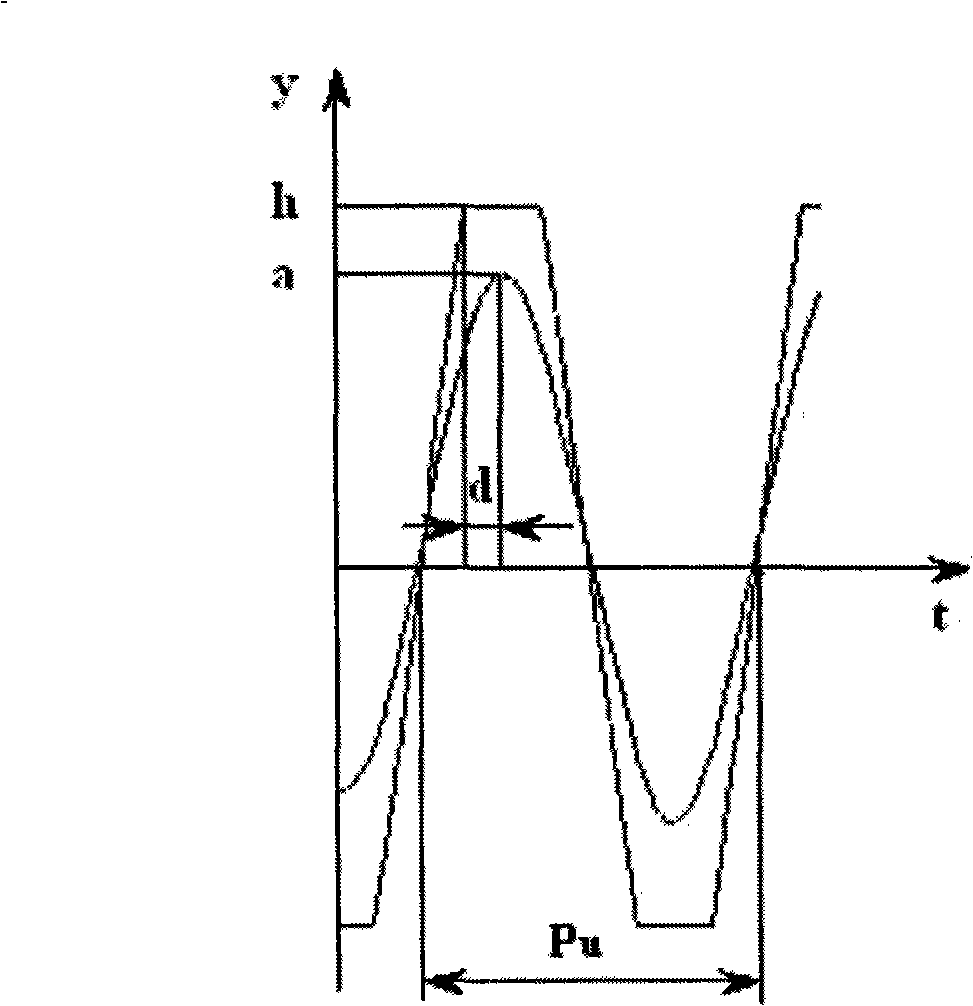

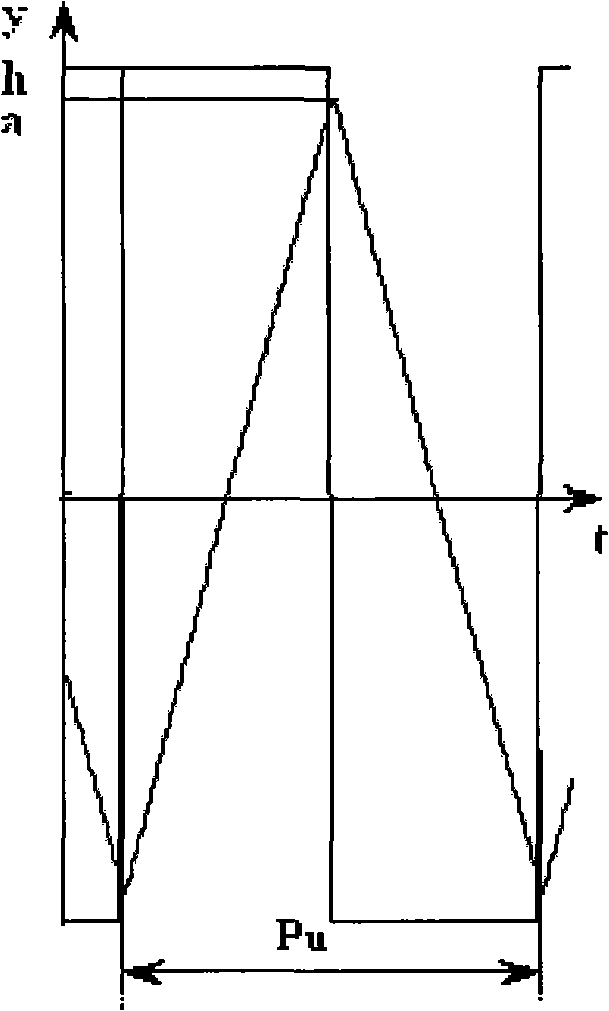

Relay feedback based AC servo system automatic setting method

InactiveCN101552589ARealize automatic tuningMotor parameters estimation/adaptationMovement controlMotion control

A relay feedback based AC servo system automatic setting method belonging to the motion control technology field comprises a speed ring setting process and a position ring setting process. The method comprises the following steps: setting the parameters of saturated relay with delay; bringing the relay identification link into the closed speed ring (or position ring) to cause the system to establish a limit ring quickly; evaluating the system delay and the limit oscillation period parameter; identifying the AC servo system model; and setting the PID control parameter automatically by the PID parameter setting principle such as pole assignment method and amplitude phase margin method according to the identified model parameters; By combining the saturated relay feedback and he PID parameter setting principle such as ITAE method and amplitude phase margin method, the invention can accomplish the parameter automatic setting to the controller of AC servo motor.

Owner:SHANGHAI JIAO TONG UNIV

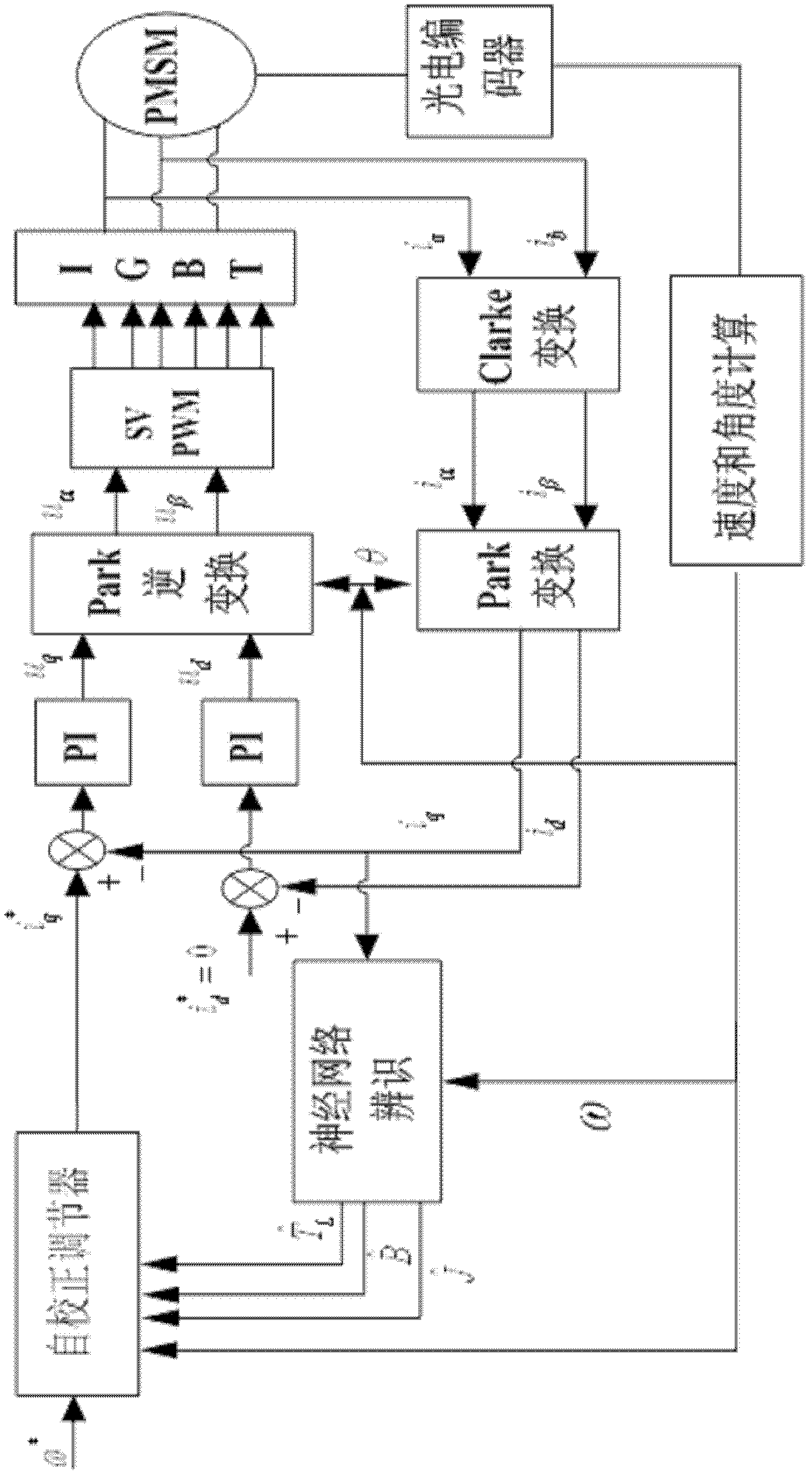

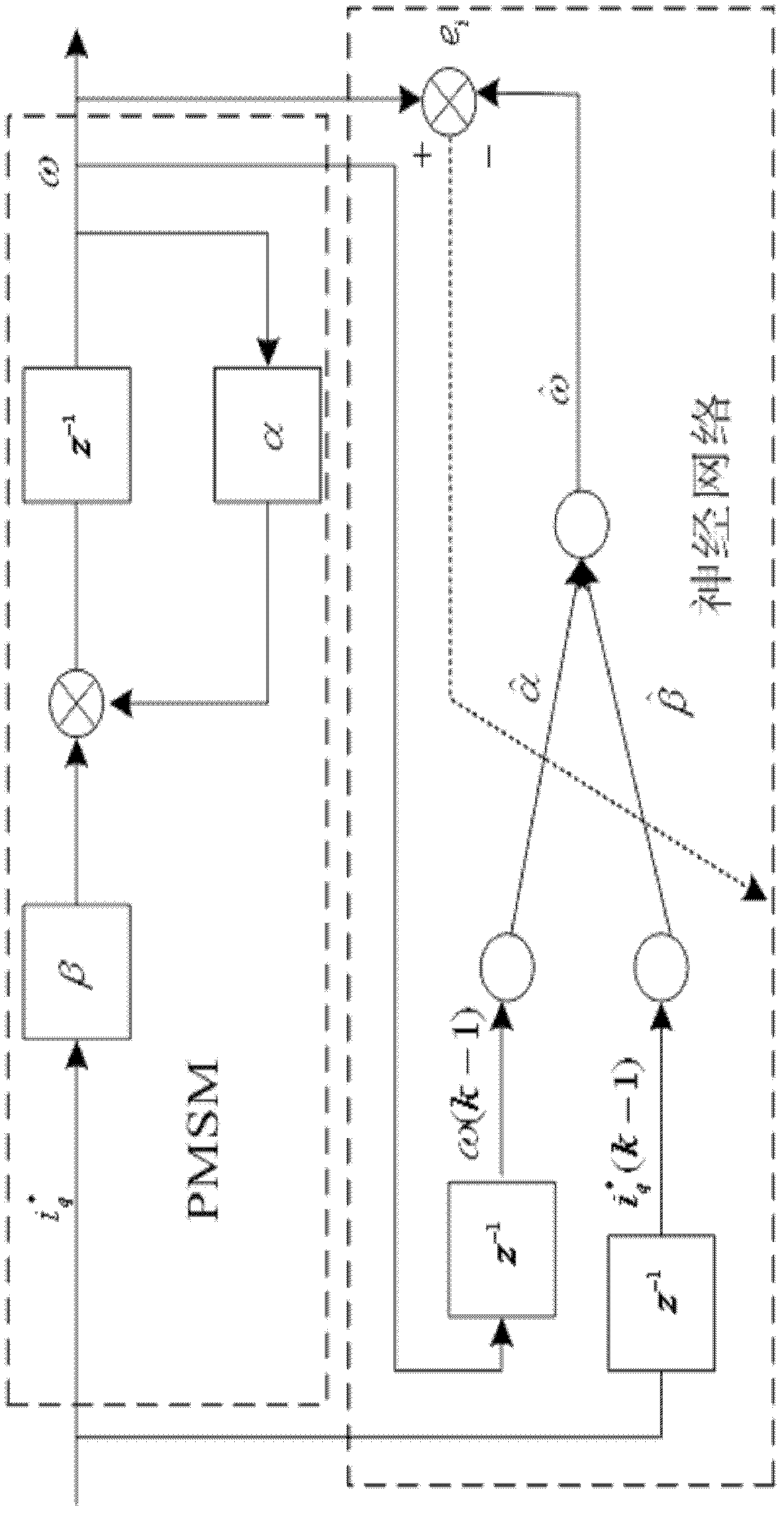

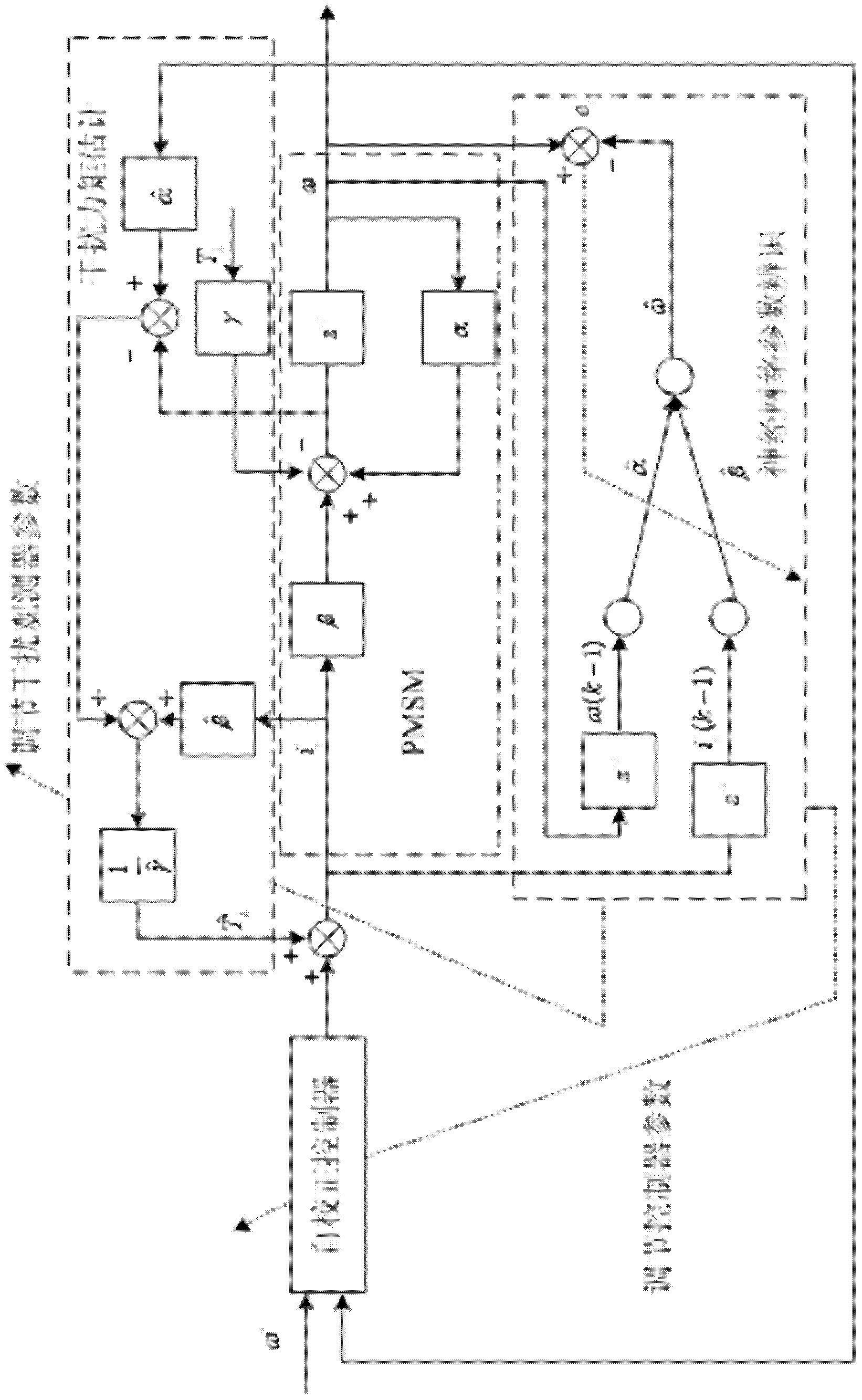

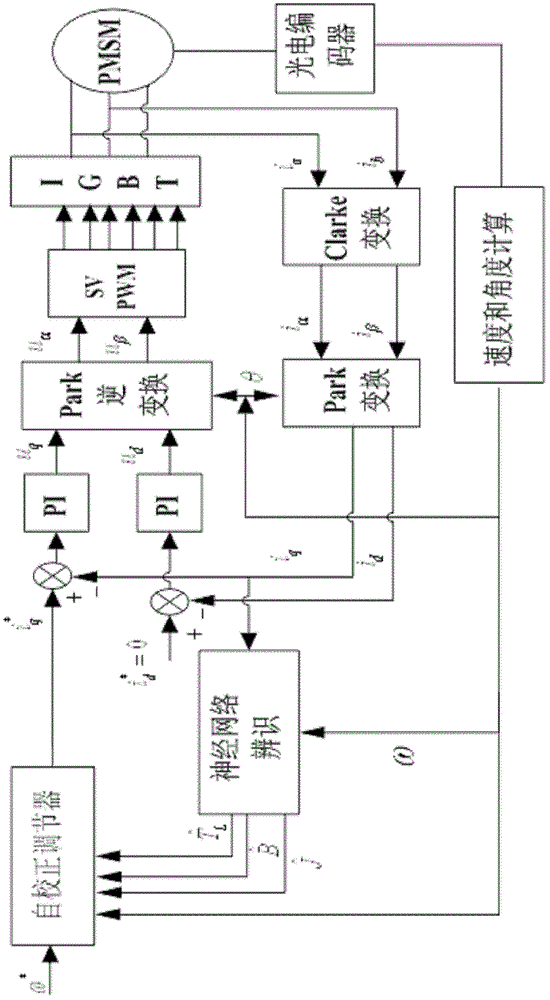

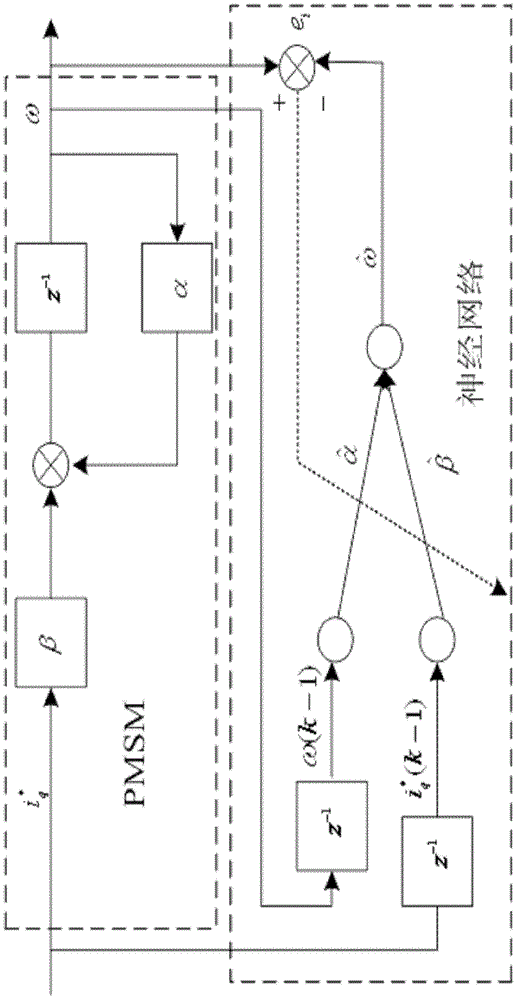

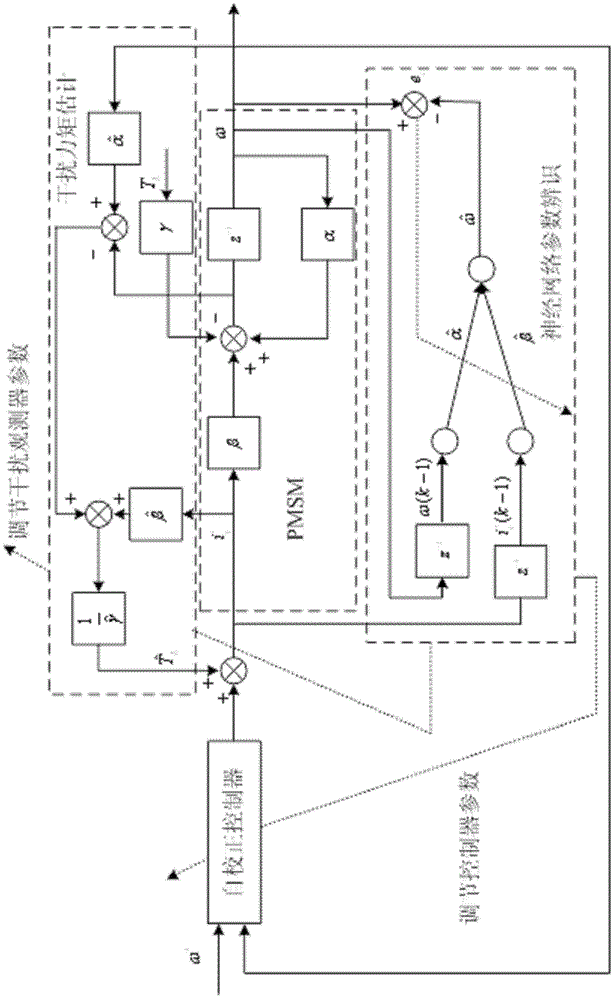

Neural-network self-correcting control method of permanent magnet synchronous motor speed loop

ActiveCN102497156AAdaptableSimple structureElectronic commutation motor controlVector control systemsPower flowLoad torque

The invention discloses a neural-network self-correcting control method of a permanent magnet synchronous motor speed loop. The method is characterized by: taking a current loop and a motor as generalized objects; firstly, collecting information, such as a rotating speed, a current and the like; using an adaptive linear time-delay neural network to carry out off-line parameter identification to the motor; then, taking a weight obtained through off-line learning as an initial value of on-line learning; finally, carrying out on-line parameter identification to the system, calculating a load torque of the motor according to the identified parameter; designing a neural-network self-correcting control law according to the obtained parameter value and a load disturbance value, adjusting the network weight on line according to an error between a controlled object and an identification model, and then setting the parameter of the neural-network self-correcting controller on line so as to realize online adjustment of the controller parameter. Uncertainty of the system and influence brought by the external disturbance can be eliminated. Dynamic performance and an anti-disturbance ability of a servo system can be improved.

Owner:SOUTHEAST UNIV +1

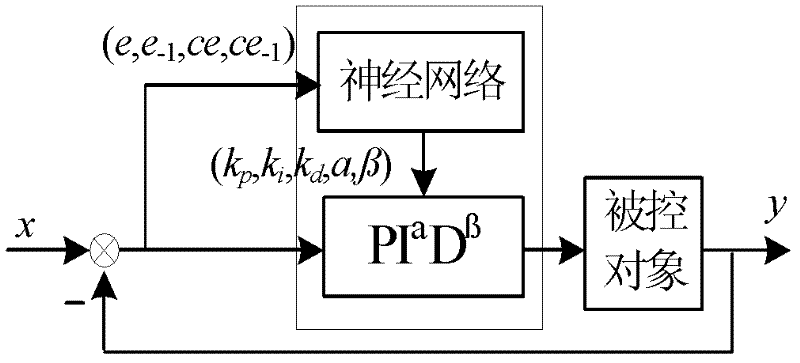

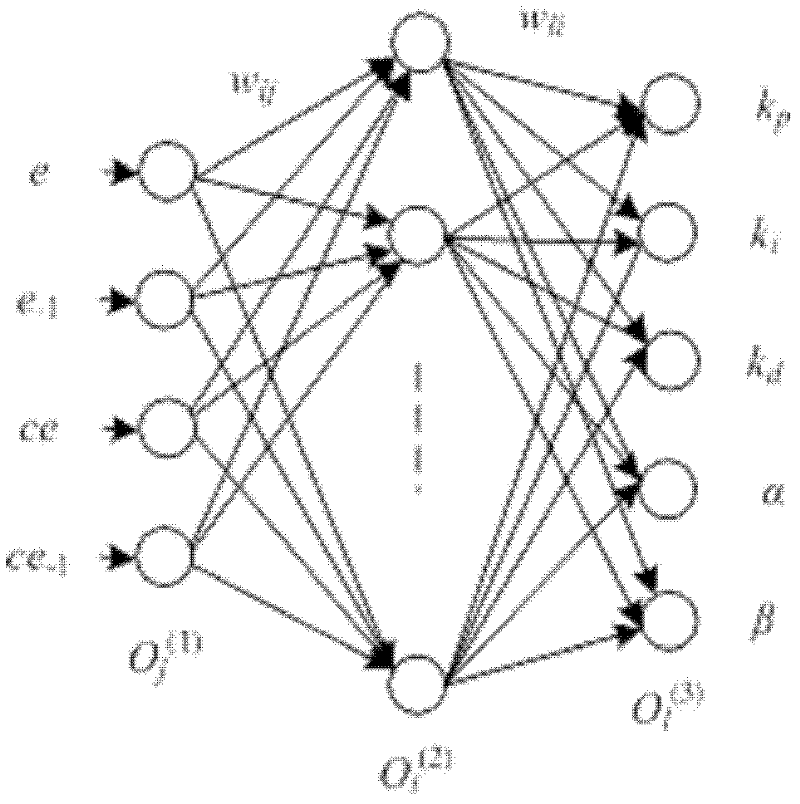

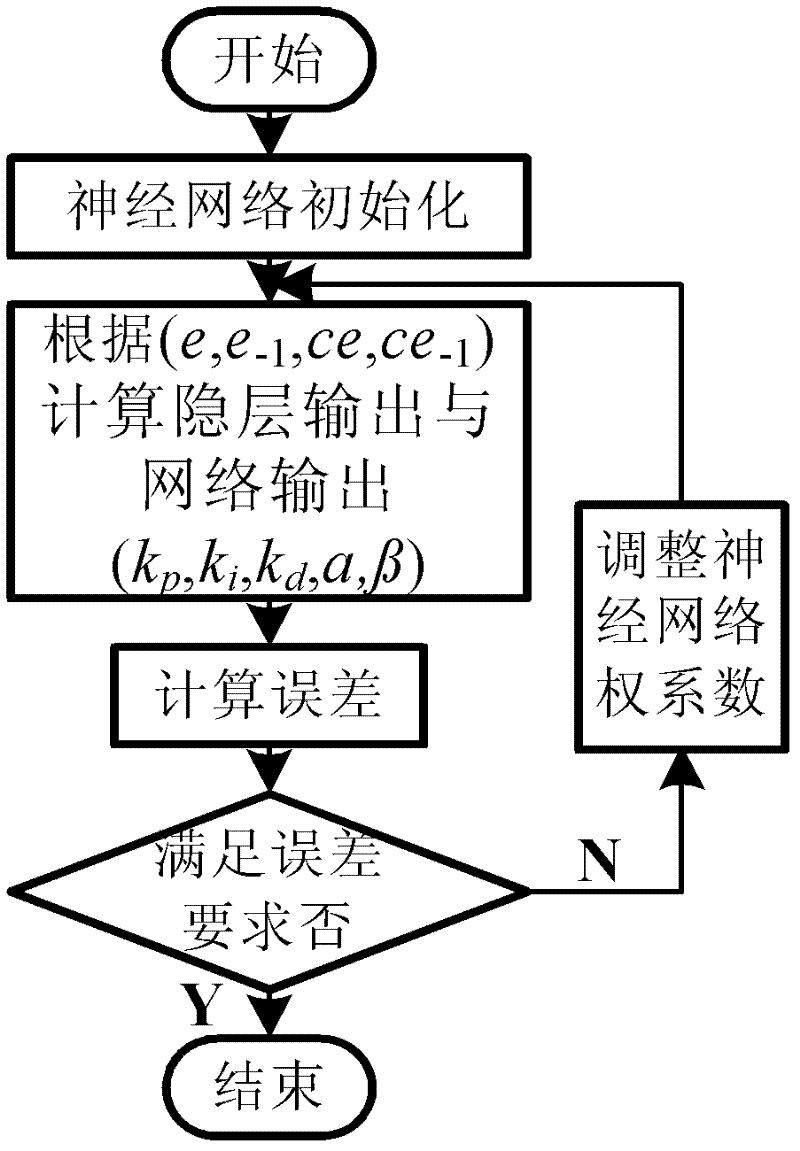

Fractional order parameter adjustment controller algorithm of PI<alpha>D<beta> controller

InactiveCN102566426AImprove adaptabilityEasy to combineAdaptive controlHidden layerFractional-order control

The invention discloses a fractional order parameter adjustment controller algorithm of a PI<alpha>D<beta> controller, which comprises the following steps of: bestowing an initial right to a neural network; calculating a change rate of errors through system output errors obtained by control periods so as to obtain an input variable of the neural network; positively calculating outputs of a hidden layer and an output layer of a network by applying formulas (1)-(8) according to a selected transfer function; calculating a system output error; and judging whether the system output error meets the error requirement. Because parallel regulation is carried out by adopting the neural network, thus compared with the linear time-invariant integer order PID controller adopted commonly at present, a fractional order parameter adjustment controller has the great advantage in the adaptability. According to the fractional order parameter adjustment controller algorithm, parameters can be automatically adjusted, and the parameters obtained by the adjustable during the use are fixed; and the parameters can be automatically adjusted in real time in an application process. The invention can realize automatic adjustment of the parameters under the condition of different objects, and realizes optimal control property.

Owner:DALIAN JIAOTONG UNIVERSITY

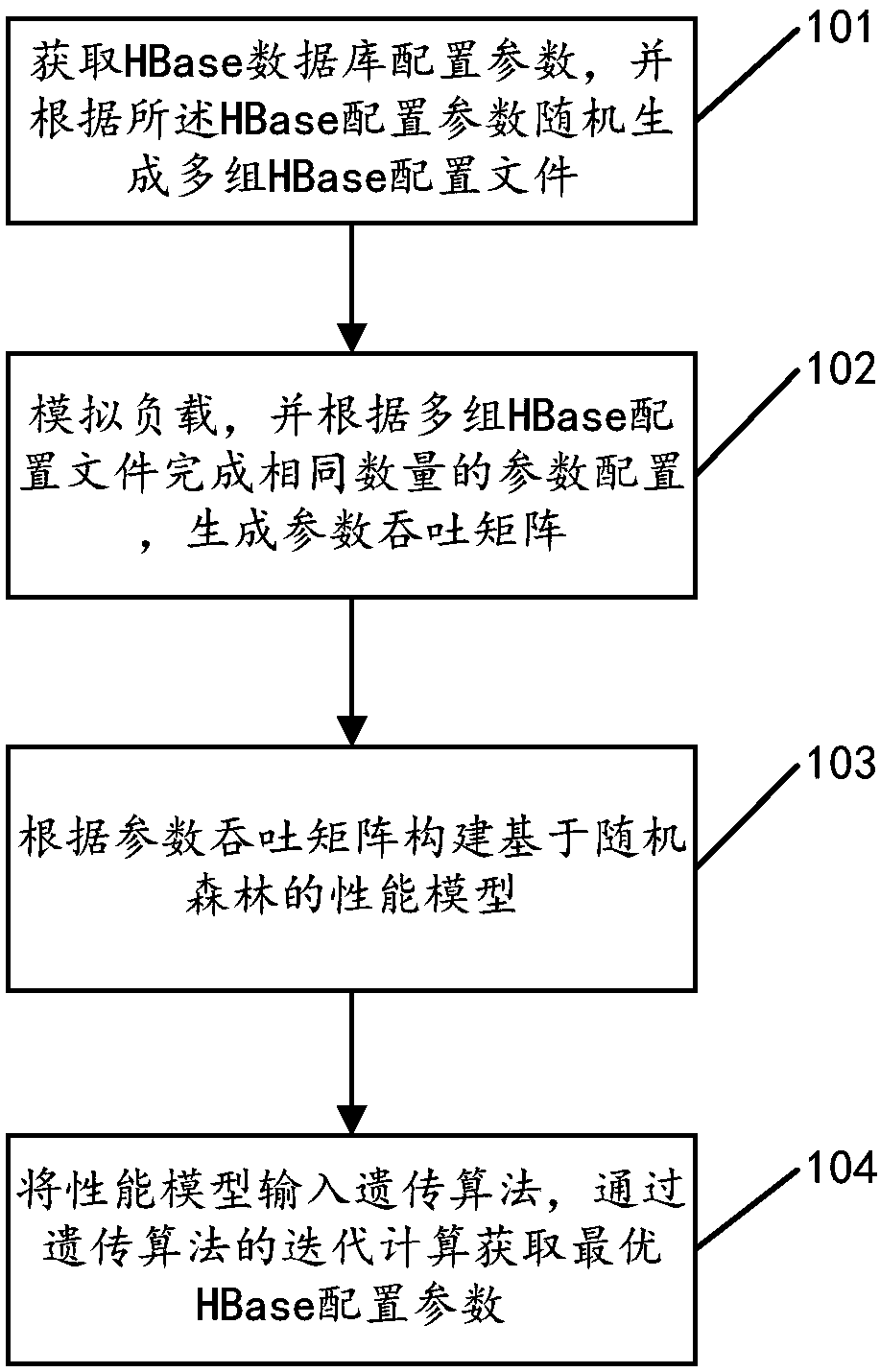

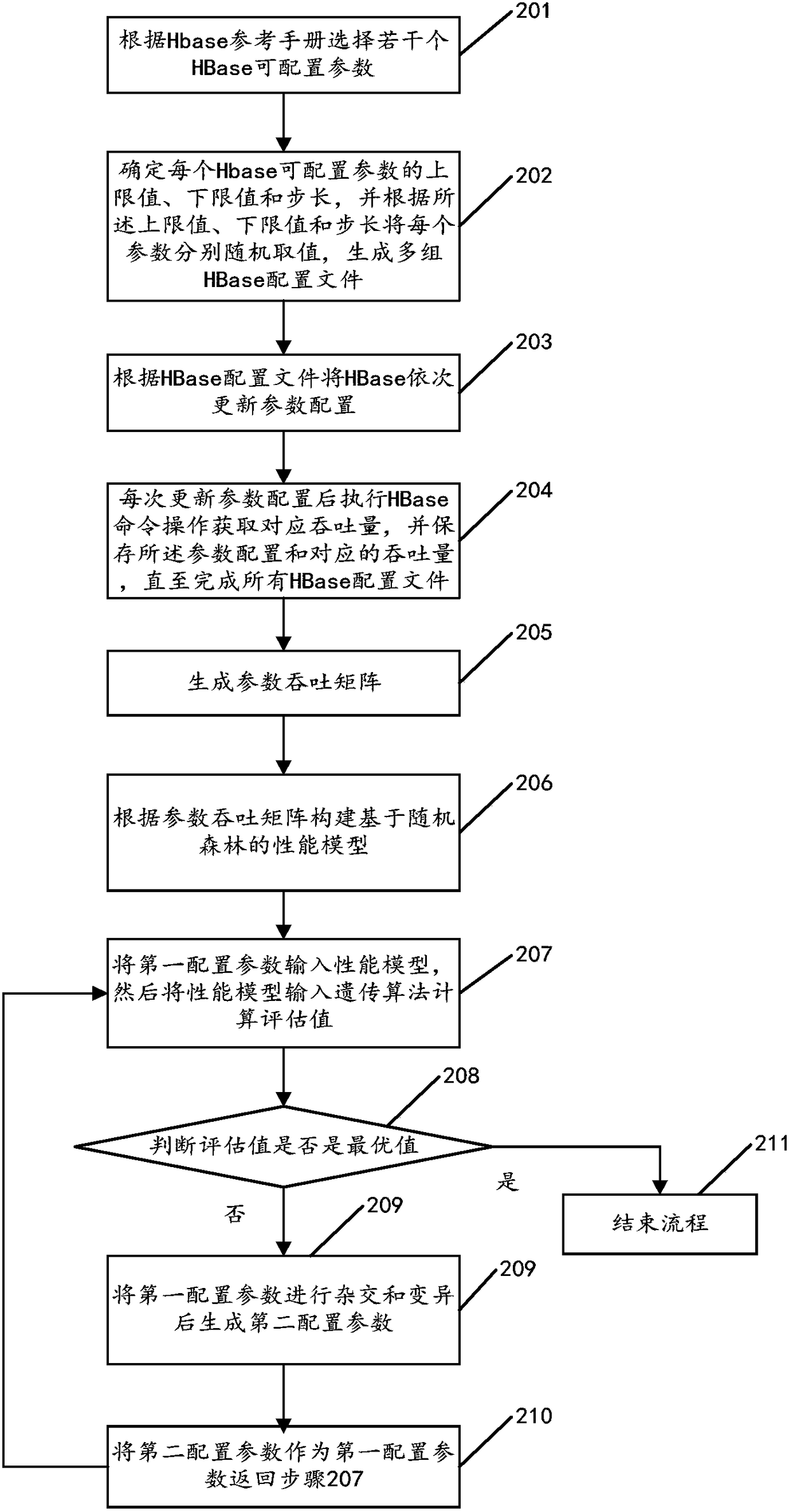

Hbase configuration parameter automatic tuning method, Hbase configuration parameter automatic tuning device and user equipment

InactiveCN108234177AAutomatic tuning of configuration parametersImprove work efficiencyData switching networksGenetic algorithmData mining

The invention discloses a HBase configuration parameter automatic tuning method, a HBase configuration parameter automatic tuning device and user equipment, the method comprises the following steps: after acquiring a HBase database configuration parameter, firstly generating multiple groups of HBase configuration files randomly according to the HBase configuration parameter, then, simulating load,completing the same number of parameter configuration according to the generated multiple groups of HBase configuration files, generating a parameter throughput matrix, constructing a performance model based on a random forest according to the parameter throughput matrix, finally, inputting the performance model into a genetic algorithm, and acquiring an optimal HBase configuration parameter through iterative computation of the genetic algorithm. Obviously, by application of the embodiment of the invention, automatic tuning of HBase configuration parameters can be realized without dependenceon personal capability and experience of an implementer, and working performance is improved greatly.

Owner:SHENZHEN INST OF ADVANCED TECH

Method, device and system for automatically adjusting and optimizing parameters of key value pair storage engine

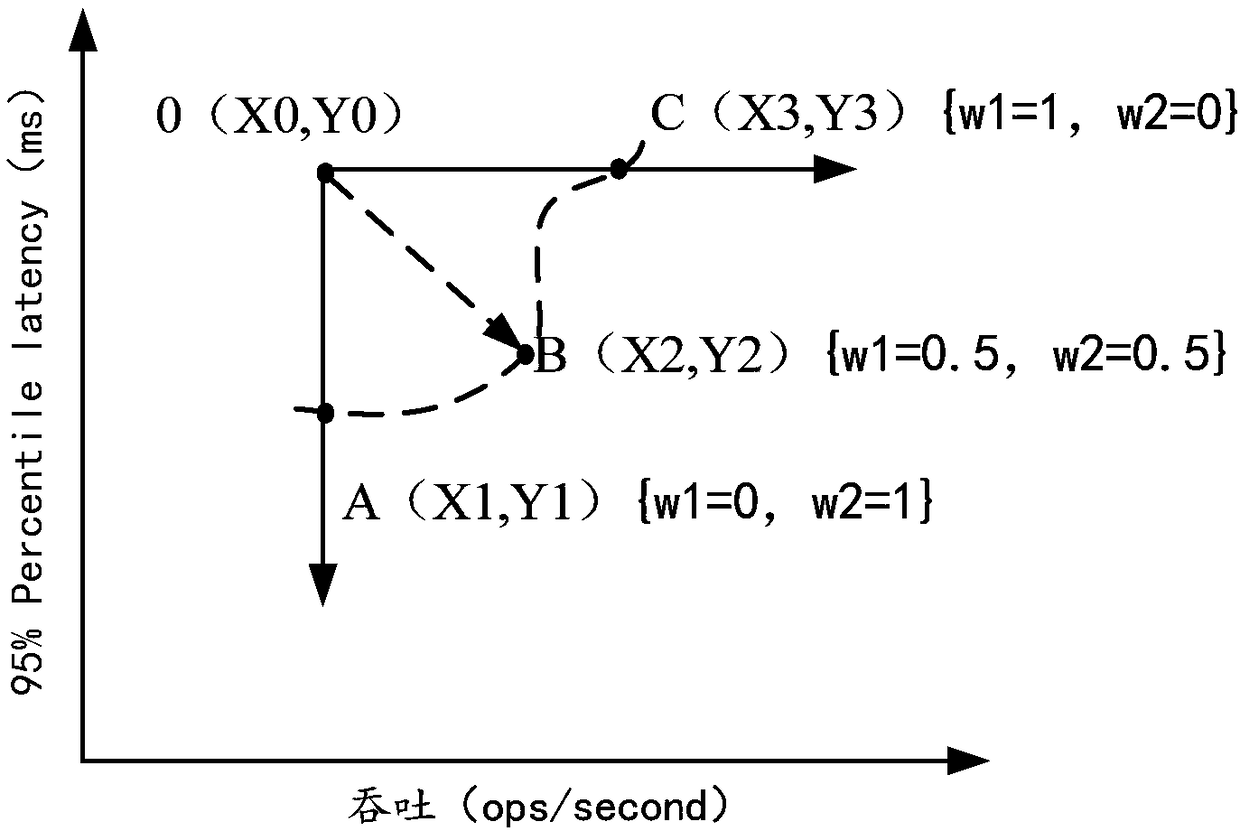

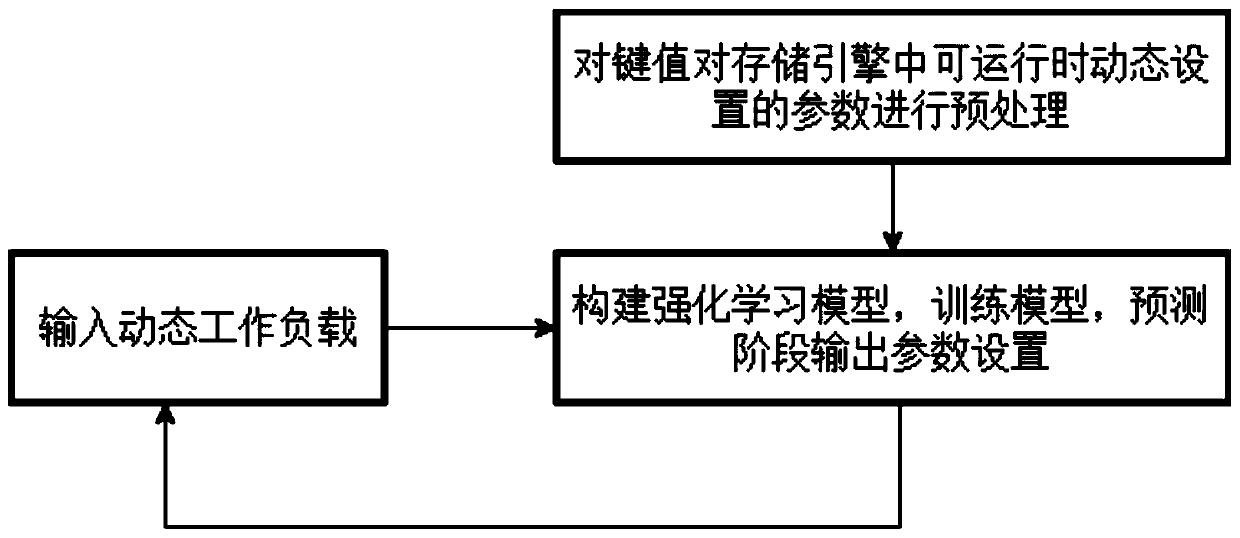

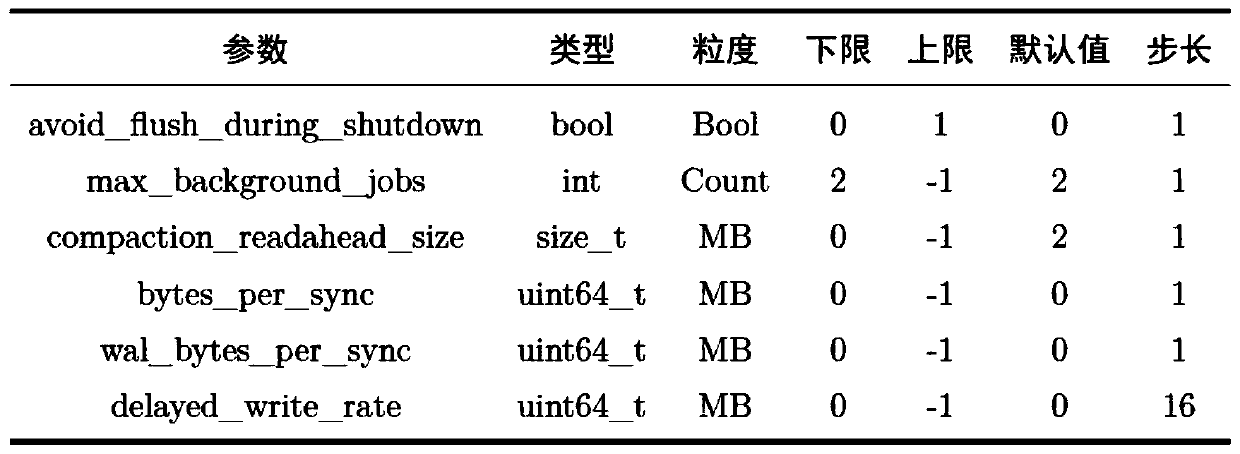

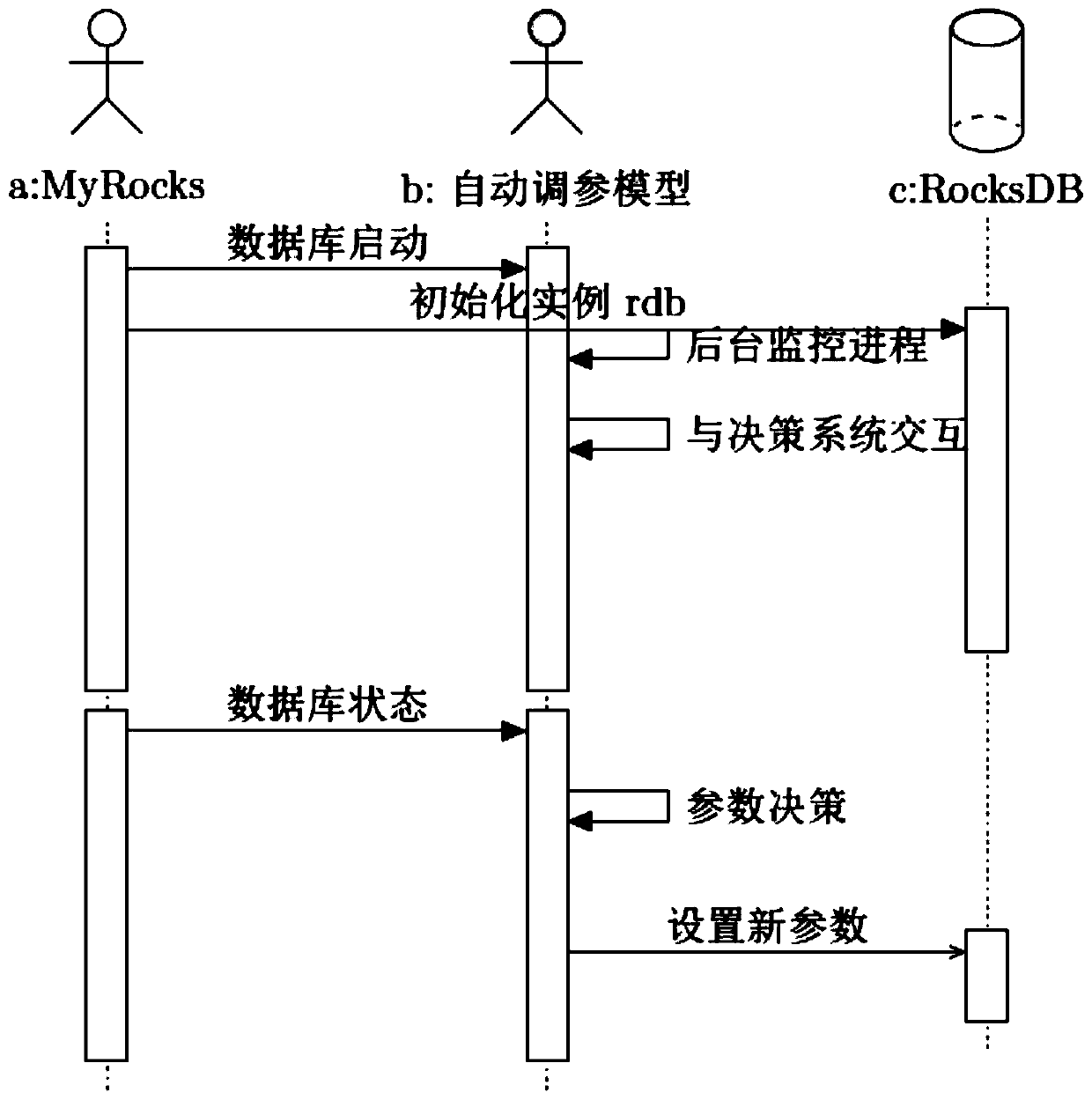

PendingCN110134697ARealize automatic tuningAddressing slow performanceNeural architecturesNeural learning methodsWorkloadData mining

The invention discloses a method, a device and a system for automatically adjusting and optimizing parameters of a key value pair storage engine, which can solve the problem that the system performance is reduced due to default parameter configuration caused by change of workload in a key value pair storage system. The method comprises the steps of preprocessing parameters according to a parameterconfiguration mode in a key value pair storage engine, and constructing a Restful service framework; constructing a Deep PILCO reinforcement learning model based on the model; operating the workloadof the upper database system, generating data and training a model; loading the model, outputting parameter configuration generated by the strategy for the input workloads, and applying the parameterconfiguration to a bottom key value pair storage engine. The invention is applied to a database system with a log structure merging tree as a storage engine and a scene where the workload changes frequently.

Owner:NANJING UNIV +2

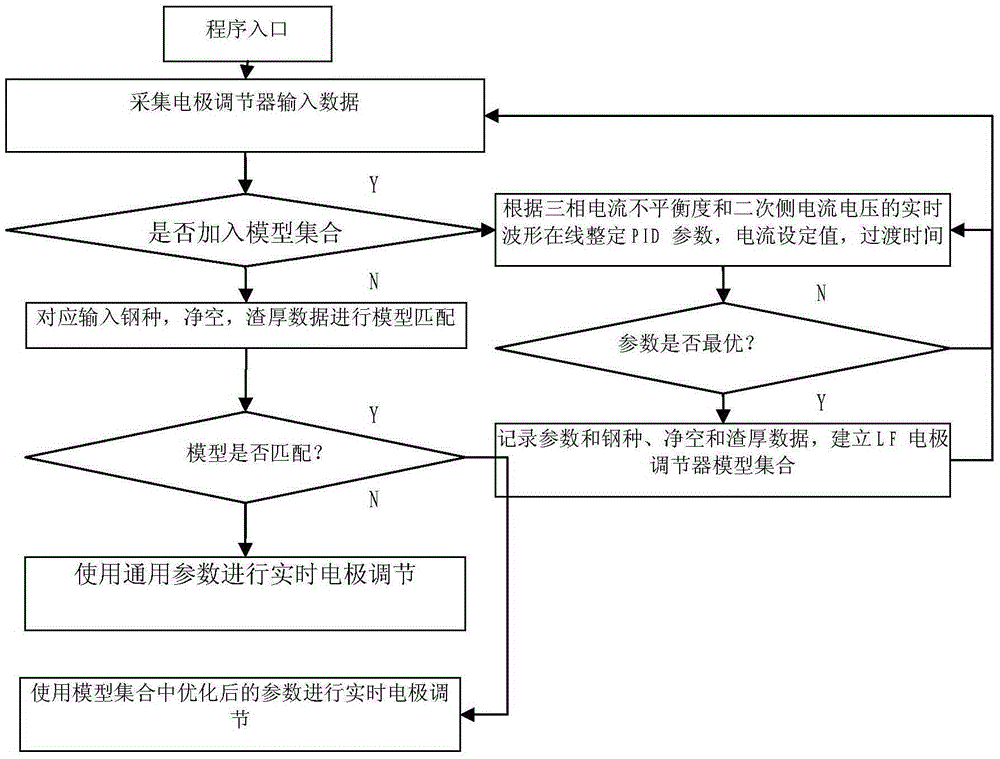

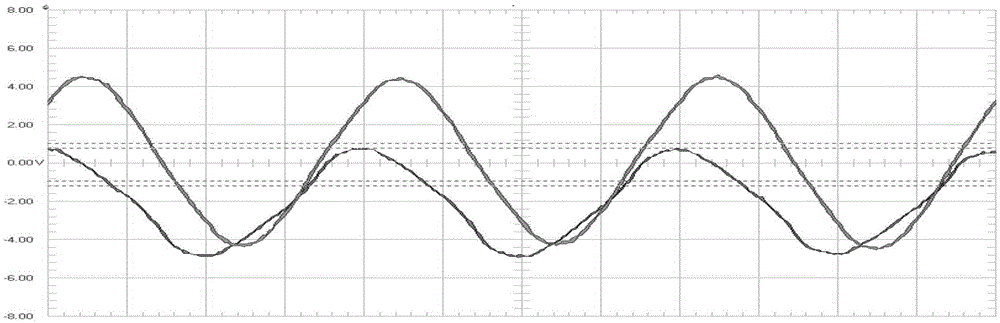

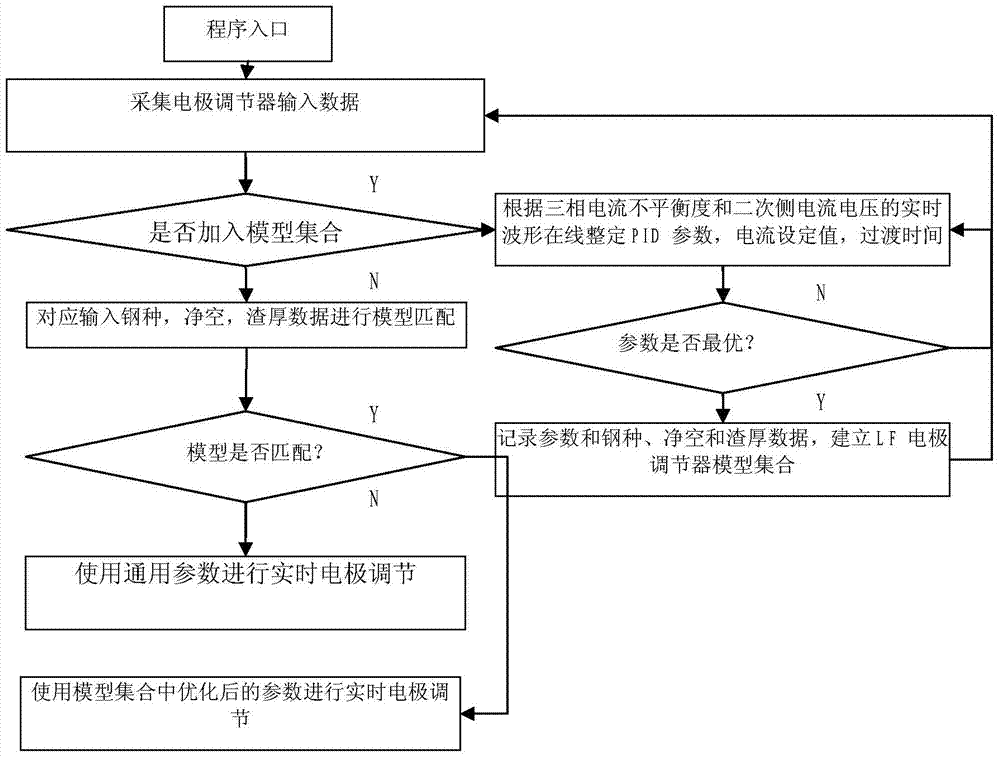

Multi-model LF furnace electrode adjusting method based on steel type clearance slag thickness

ActiveCN105404149AEasy to controlRealize automatic tuningIncreasing energy efficiencyControllers with particular characteristicsReal-time Control SystemSlag

The invention, which belongs to the field LF furnace electrode regulator field, relates to a multi-model LF furnace electrode adjusting method based on steel type clearance slag thickness. With the method, problems that the sensitivity of the controller is low and the network is not suitable for a real-time control system can be solved. Input data of an electrode regulator are collected, wherein the data include a three-phase secondary side current and three-phase secondary side voltage that are obtained by direct measurement, an initial current setting value of the electrode regulator, and data of the steel type, clearance, and slag thickness for setting a PID controller; according to the data, parameters of the PID controller are set in an on-line mode; static parameters of the set PID controller as well as the data of the steel type, clearance, and slag thickness are recorded, and an LF electrode PID setting model set is established; and after establishment of the PID setting model set, data of the steel type, clearance, and slag thickness are inputted, determination is carried out, and a proper model is invoked automatically. Therefore, optimization of an original control system is realized, thereby substantially improving the on-line adjusting process of the system and realizing better control of the electrode.

Owner:BENGANG STEEL PLATES +1

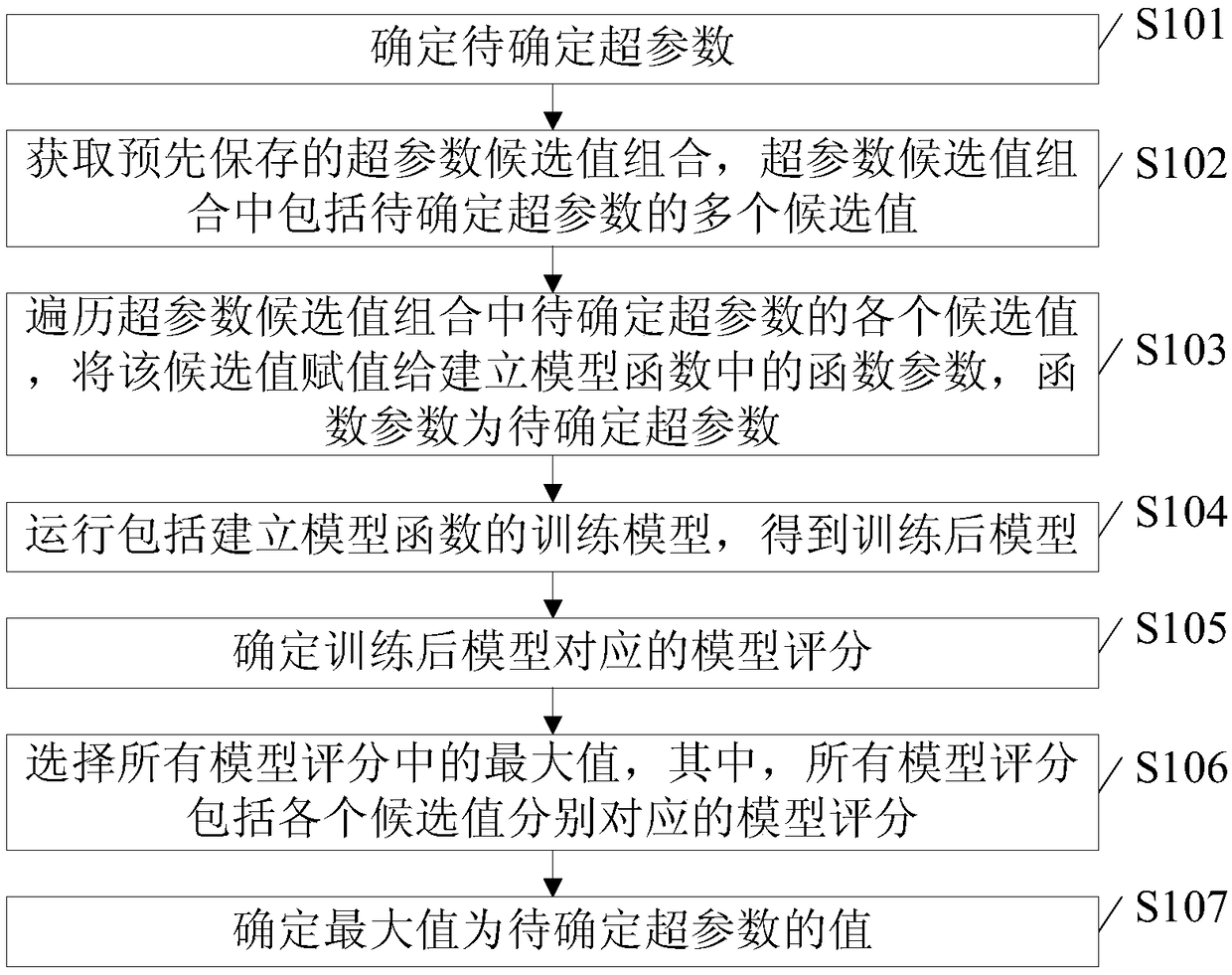

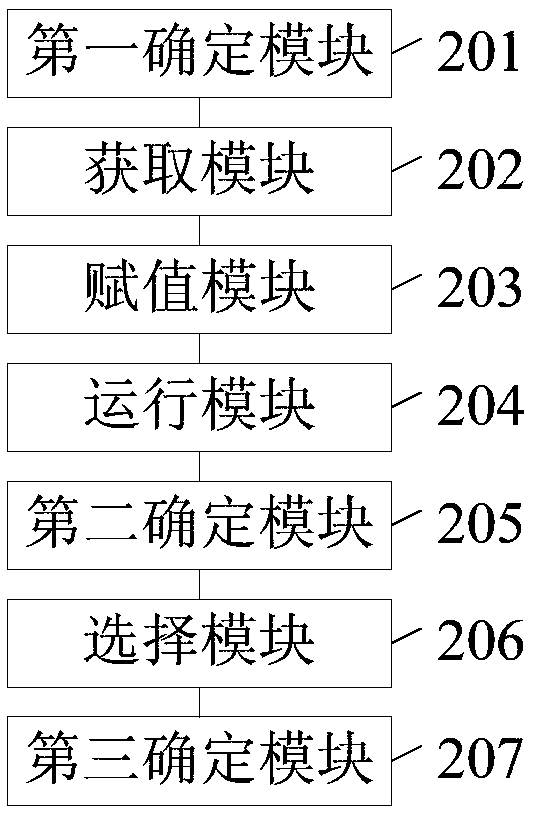

Super parameter tuning method, apparatus and device

InactiveCN109284828AReduce complexityRealize automatic tuningNeural learning methodsData miningAlgorithm

The embodiment of the invention provides a super parameter tuning method, an apparatus and a device. The method comprises the following steps: determining a super parameter to be determined; acquiringa preserved super-parameter candidate value combination, wherein the super-parameter candidate value combination comprises a plurality of candidate values of the super-parameter to be determined; traversing each candidate value of the super-parameter to be determined in the super-parameter candidate value combination, and assigning the candidate value to the function parameter in the establishedmodel function, wherein the function parameter is the super-parameter to be determined; running a training model including the model establishing function, and obtaining the model after training; determining the model score corresponding to the model after training; selecting the maximum value of all model scores, wherein, all model scores include the model scores corresponding to each candidate value; the maximum value is determine to be that value of the super-parameter to be determine. The super parameter tuning method, the apparatus and the device provided by the embodiment of the invention can realize the automatic tuning of the super parameter and reduce the complexity of the super parameter tuning process.

Owner:沈文策

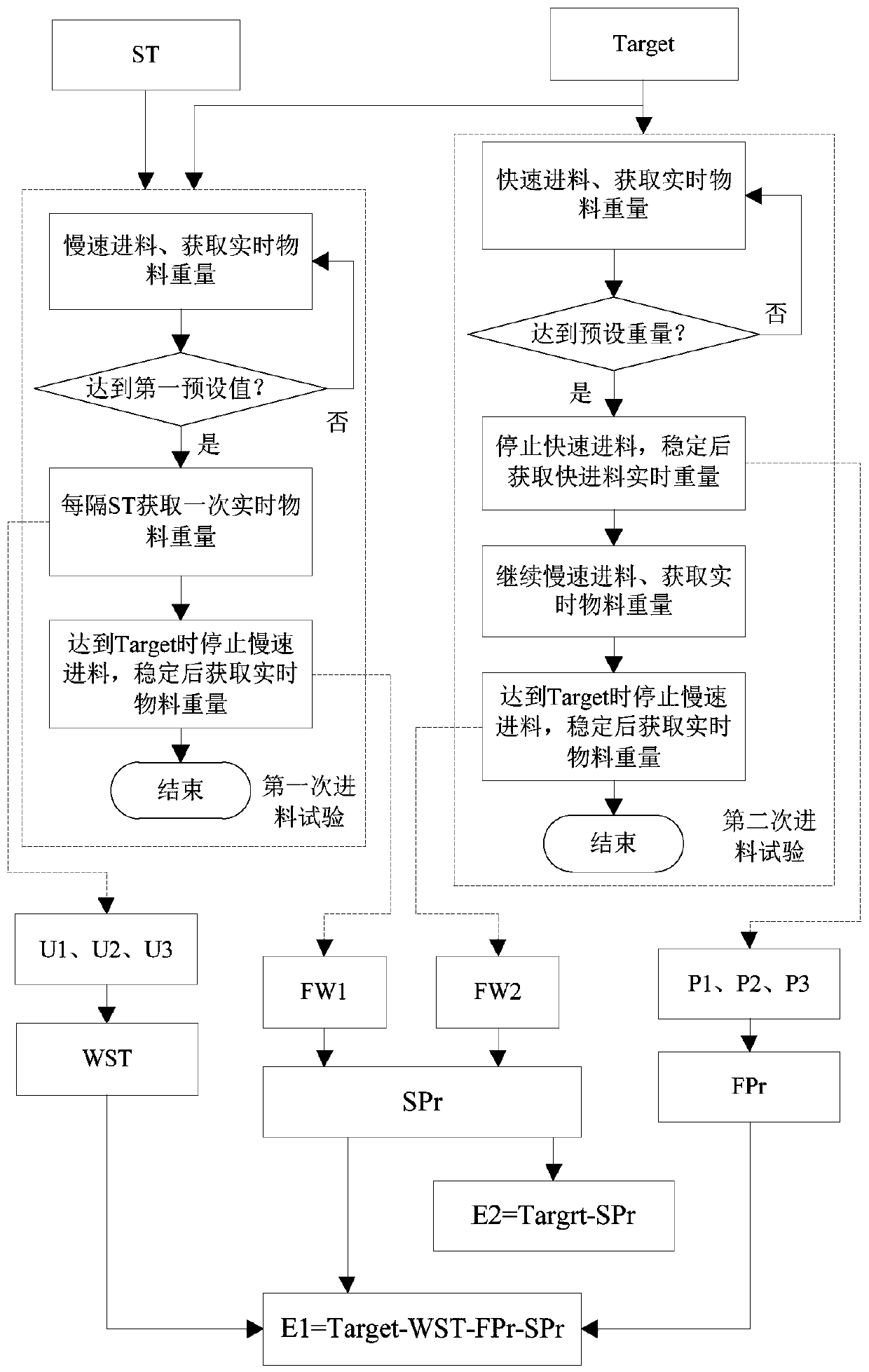

Automatic setting and optimizing method for working parameters of automatic quantitative packing scale

ActiveCN110949706AGet rid of technology level dependenceRemove the complexity factorSolid materialControl engineeringTarget weight

The invention discloses an automatic setting and optimizing method for working parameters of an automatic quantitative packing scale, and relates to the field of automatic quantitative packing scales.The method comprises the steps that a feeding test of whole-process slow feeding is conducted, and then a feeding test of rapid feeding and then slow feeding is conducted; in the two feeding tests, according to the obtained target weight and the slow feeding stable duration, a plurality of key node data are obtained, and according to the obtained key node data, automatic setting and automatic optimizing of two important parameters of the rapid feeding end weight and the slow feeding end weight can be achieved. According to the automatic setting mode, the dependence on the technical level of an operator is eliminated, the complexity factor of material characteristics is eliminated, and the accuracy and the efficiency are high; the automatic quantitative packing scale can exert the speed tothe maximum extent under the condition that the national specified precision requirement is met; and meanwhile, whether the whole parameter setting and optimizing process is stable and reliable or not can be automatically judged, and the trust condition is met.

Owner:无锡市瑞利技术开发有限公司

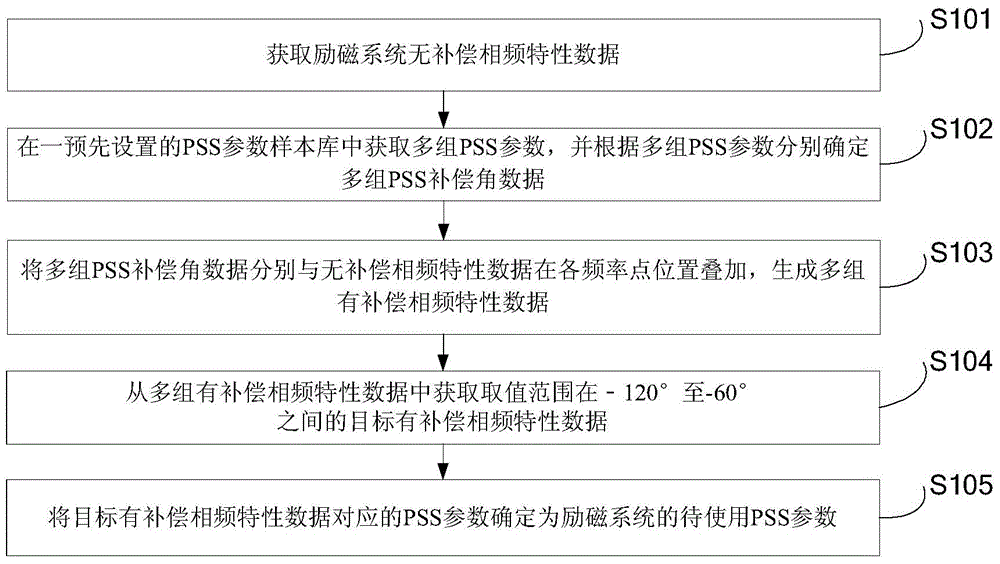

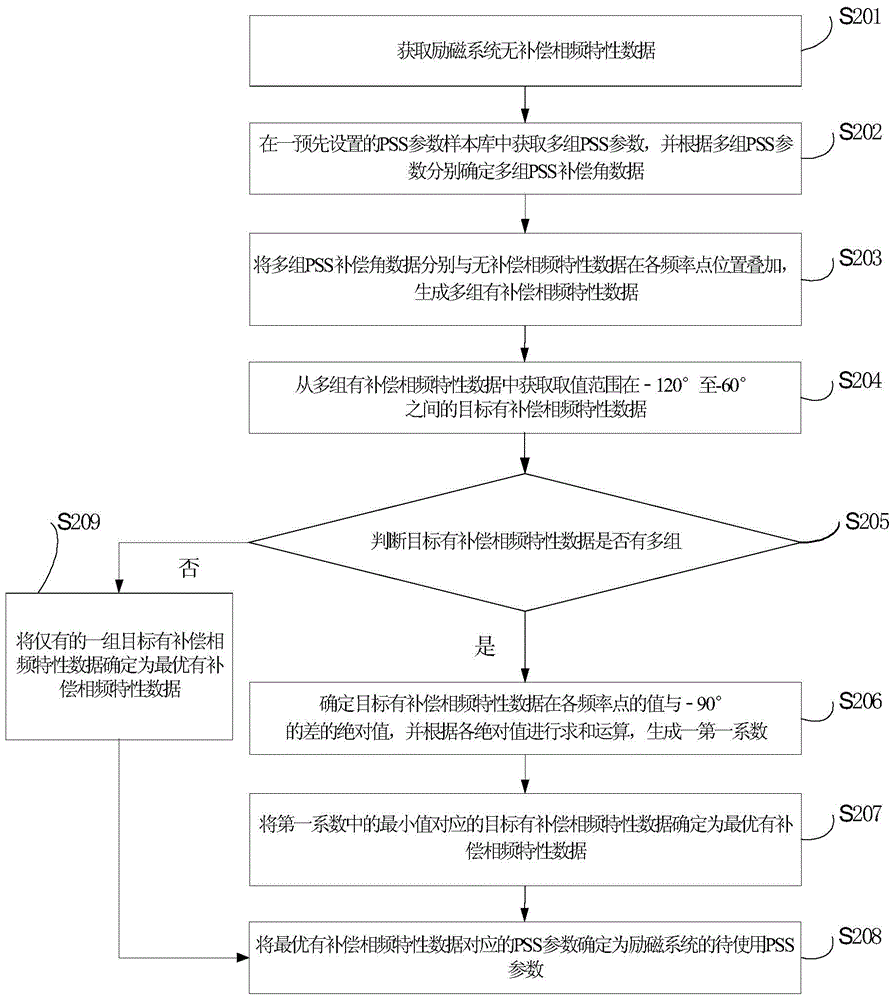

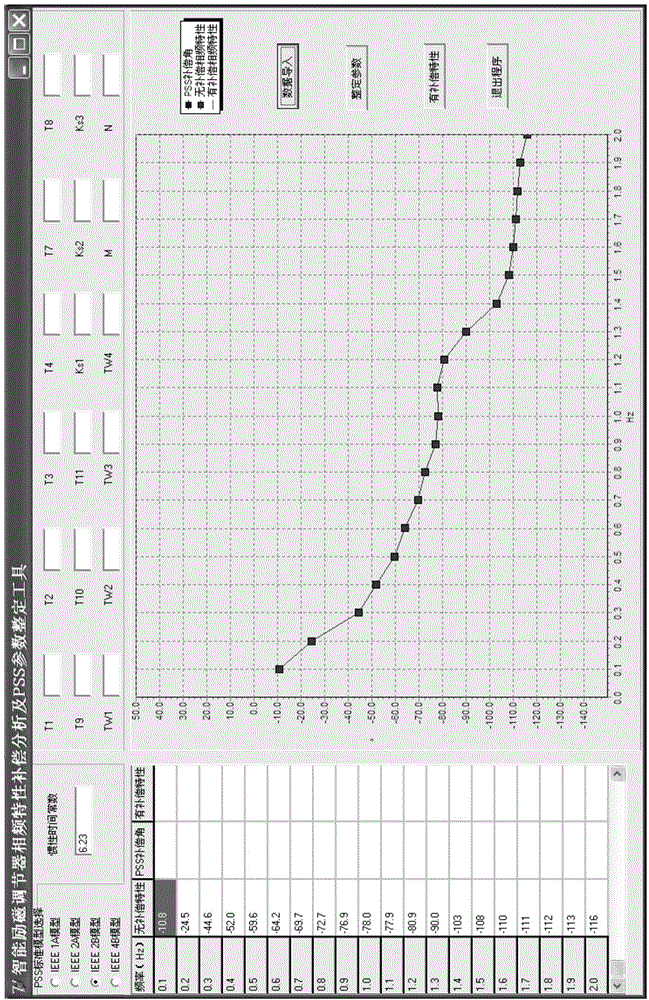

Excitation system PSS parameter setting method and device

ActiveCN105811395ARealize automatic tuningThe result is obviousPower oscillations reduction/preventionSpecial data processing applicationsTrial and errorFrequency characteristic

The invention provides an excitation system PSS parameter setting method and a device and belongs to the technical field of an excitation system. The method comprises steps that the uncompensated phase-frequency characteristic data of the excitation system is acquired; multiple sets of PPS parameters are acquired from a preset PSS parameter sample database, and multiple sets of PSS compensation angle data are respectively determined according to the multiple sets of PPS parameters; the multiple sets of PSS compensation angle data and the uncompensated phase-frequency characteristic data realize superposition at each frequency point position respectively, and multiple sets of compensation phase-frequency characteristic data are generated; the target compensation phase-frequency characteristic data in a value range of -120-60 DEG is acquired from the multiple sets of compensation phase-frequency characteristic data; PSS parameters corresponding to the target compensation phase-frequency characteristic data are determined to be to-be-used PSS parameters of the excitation system. According to the method, problems that PSS parameters acquired through a trial-and-error approach in the prior art are not more-optimized PSS parameters and the PSS parameter setting process is relatively more complex and tedious are solved.

Owner:STATE GRID CORP OF CHINA +1

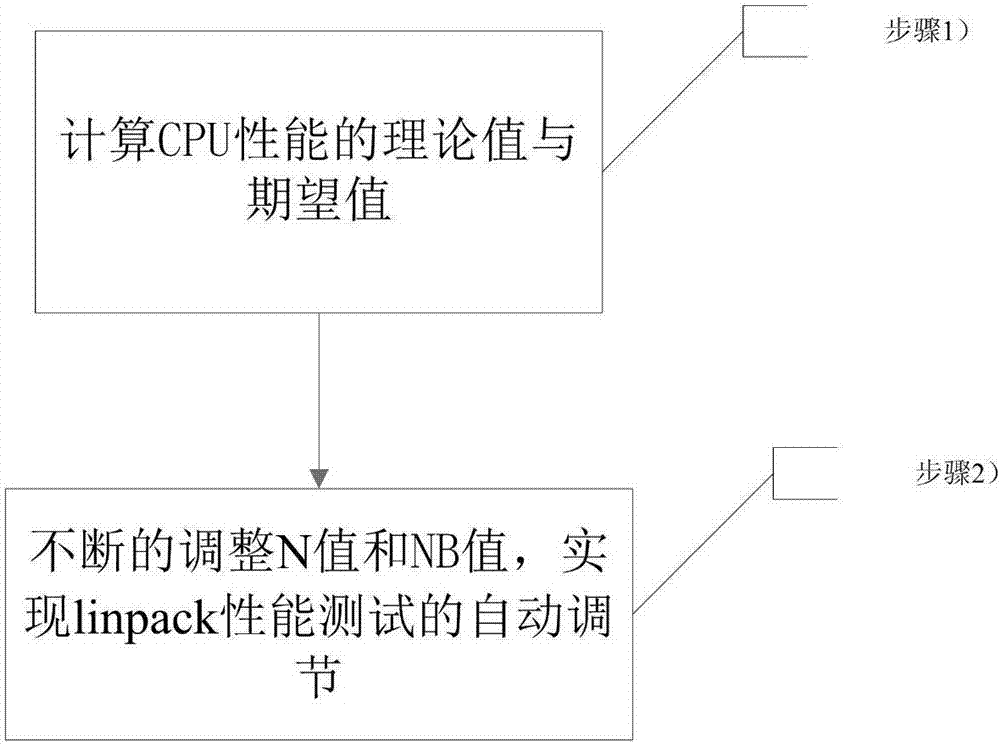

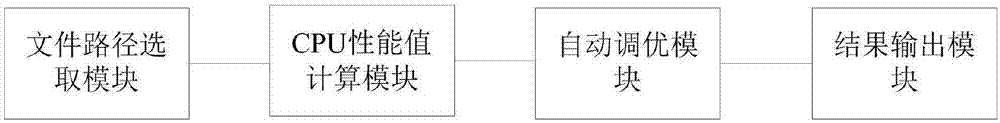

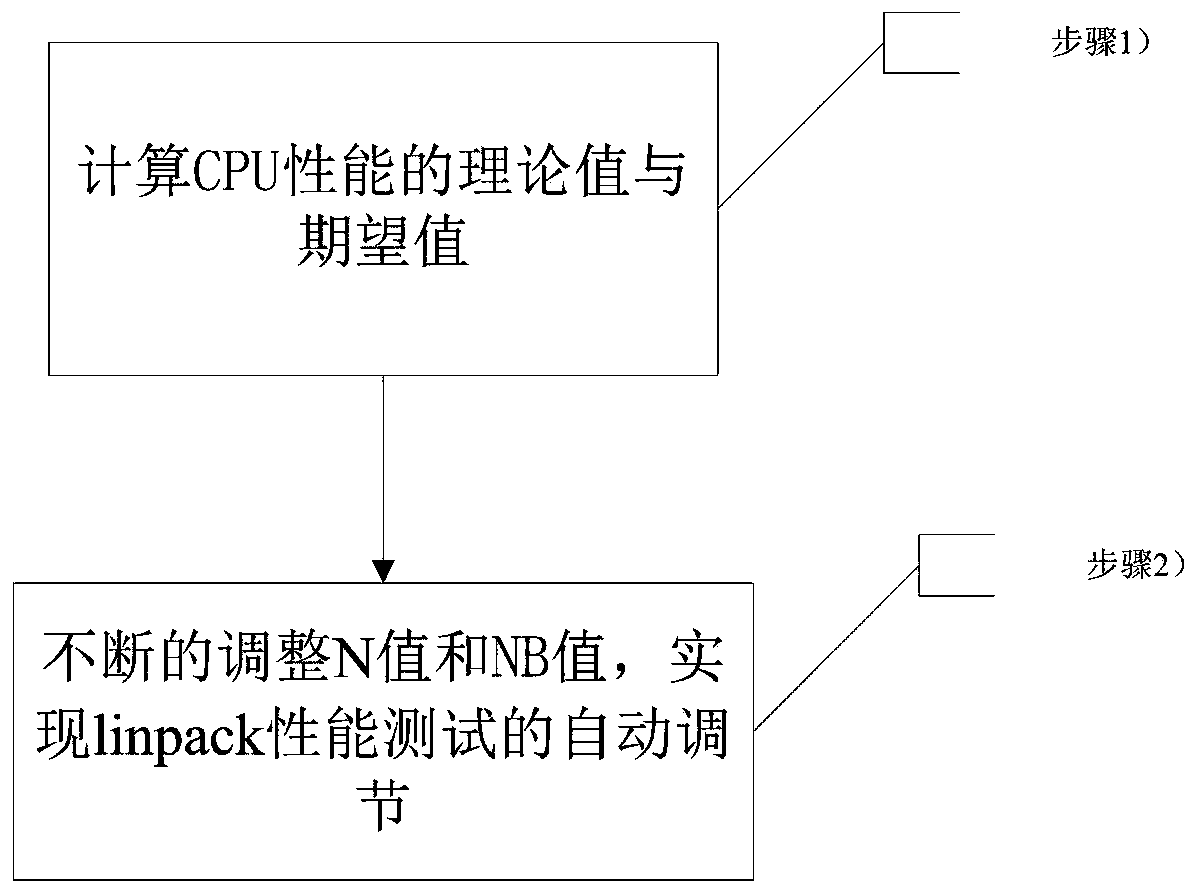

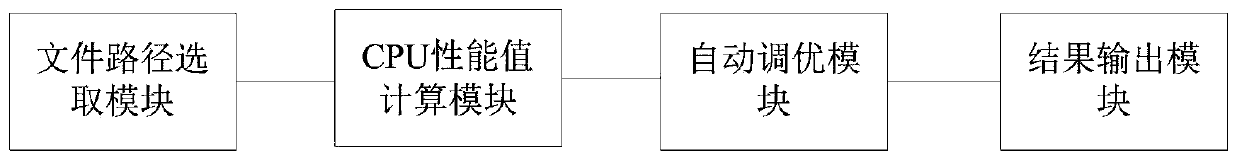

Method and system for automatic adjustment of linpack performance test

ActiveCN107451022ARealize automatic tuningRealize automatic configurationDetecting faulty hardware by configuration testFaulty hardware testing methodsAutomationOperations order

The invention provides a method for automatic adjustment of a linpack performance test. The method specifically includes the following steps that the theoretical value and expected value of CPU performance are calculated; the N value and the NB value are continuously adjusted, and automatic adjustment of the linpack performance test is achieved. The invention further provides a system for automatic adjustment of the linpack performance test. The system comprises a CPU performance value calculation module and an automatic optimization module, wherein the CPU performance value calculation module is used for reading the information of the core number, the number and basic frequency of a CPU, and calculating the theoretical value and expected value of the CPU performance; the automatic optimization module is used for modifying the NB value and N value of a configuration file, wherein N represents the operation order of a linpack, and NB represents the size of a solved matrix block. Automatic optimization of the linpack performance test can be achieved, automated configuration is achieved, automatic running of the test is achieved, the optimal result is output, it is unnecessary to artificially modify the configuration file, the labor resource and the time resource of the test are saved, and simplification and automation of the test are achieved.

Owner:ZHENGZHOU YUNHAI INFORMATION TECH CO LTD

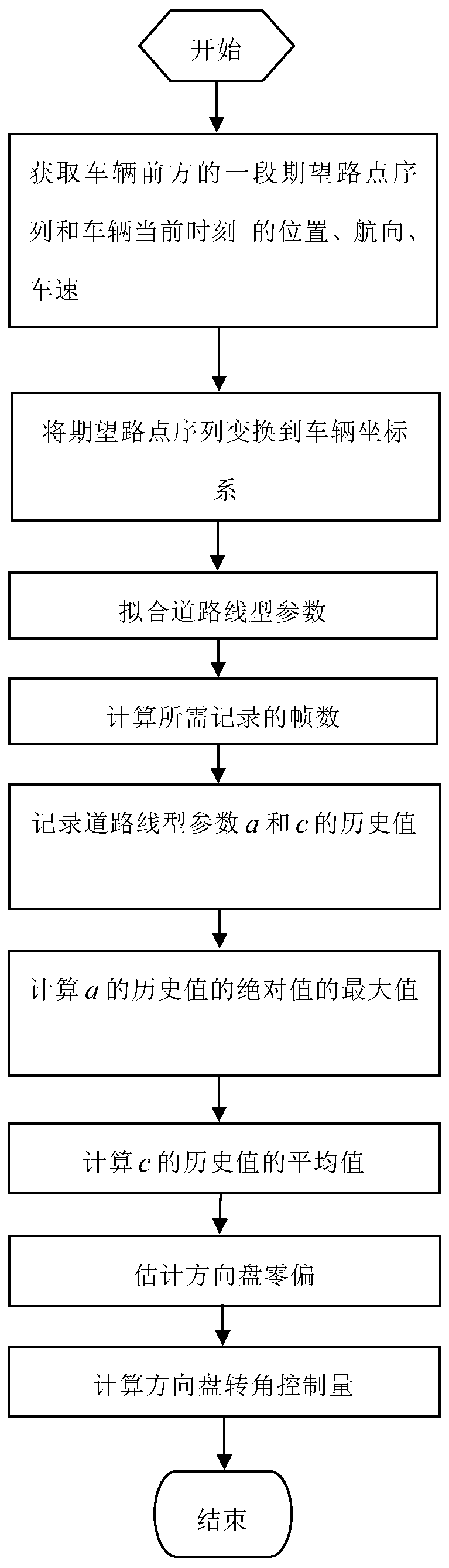

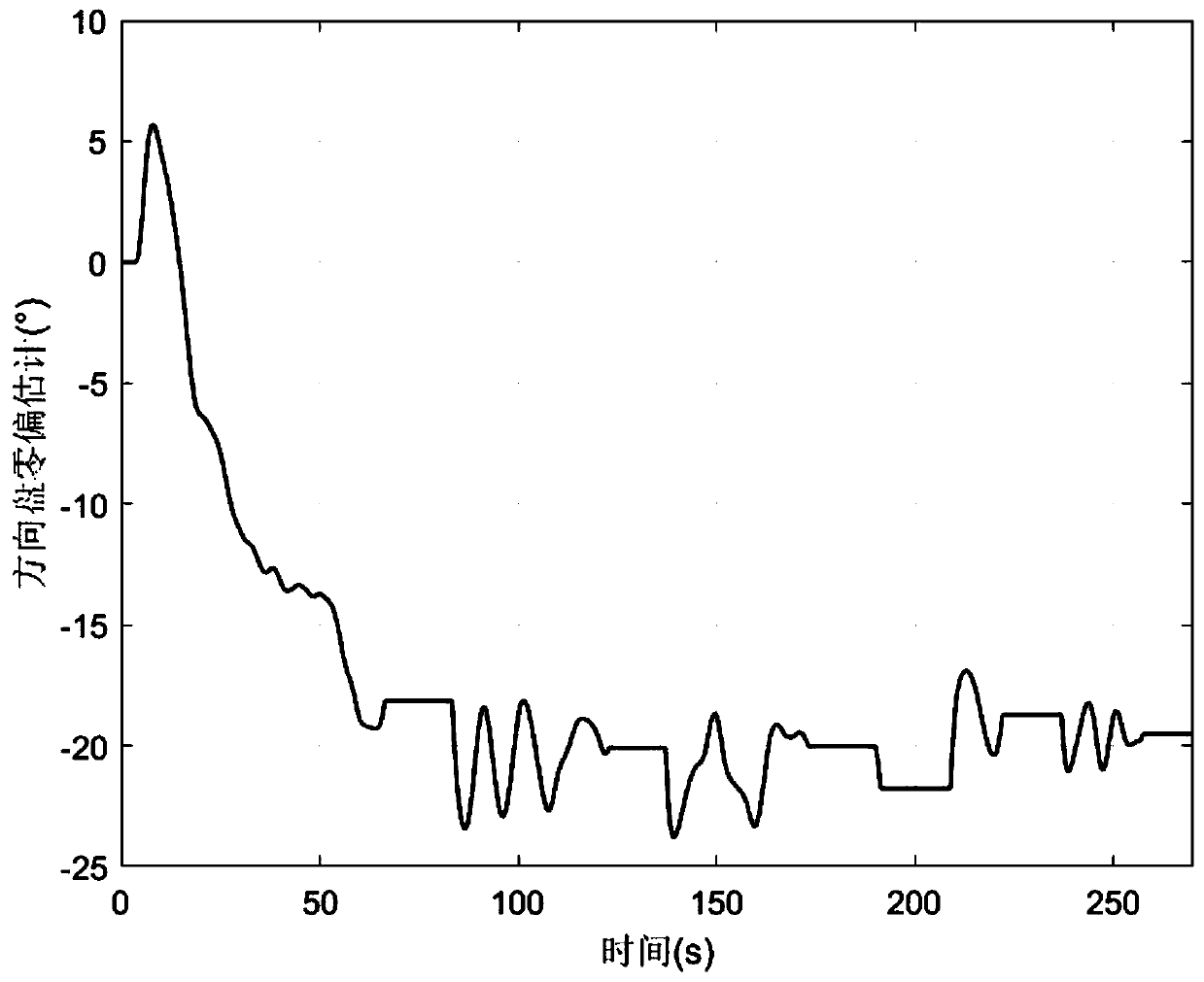

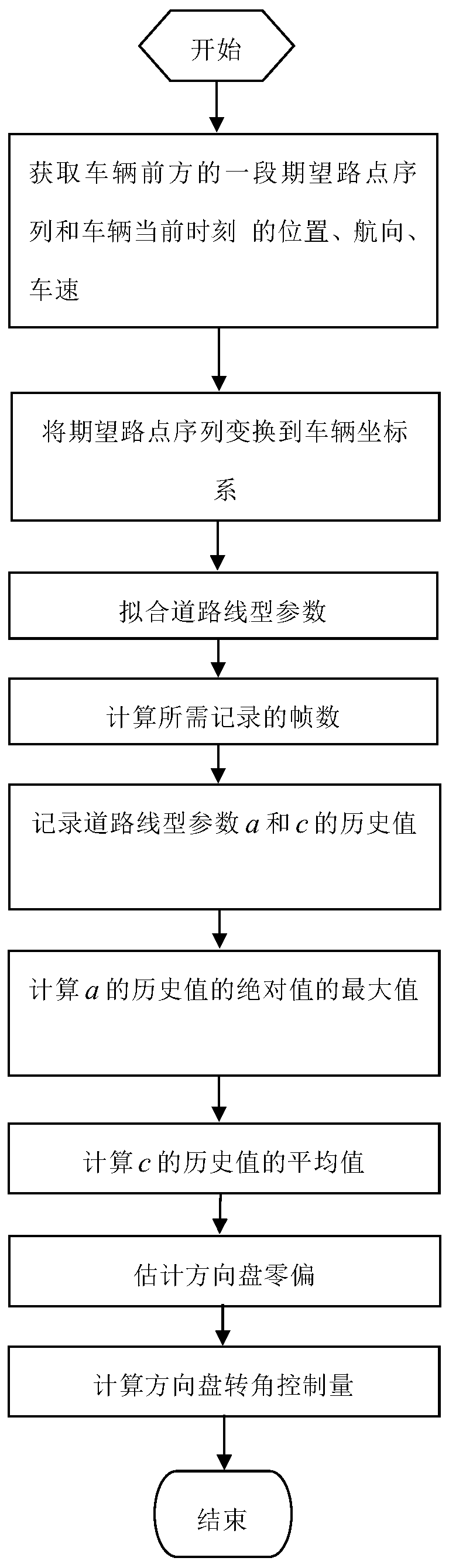

Steering wheel zero offset self-learning unmanned vehicle trajectory tracking method

ActiveCN111158379ANo additional testing costsRealize automatic tuningPosition/course control in two dimensionsVehiclesSteering wheelClassical mechanics

The invention discloses a steering wheel zero offset self-learning unmanned vehicle trajectory tracking method. The method comprises a road line type fitting algorithm, a steering wheel zero offset estimation algorithm and a vehicle kinematics model control algorithm. The road line type fitting algorithm uses a section of expected road point sequence in front of a vehicle as input to fit road linetype parameters. Steering wheel zero offset is estimated by a steering wheel zero offset estimation algorithm according to the current and historical road line type parameters. A vehicle kinematics model control algorithm is combined with the road line type parameters, the steering wheel zero offset and the vehicle kinematics model to calculate and output a steering wheel angle for vehicle trajectory tracking control. The method aims to improve the intelligent level of unmanned vehicle trajectory tracking control and improve the tracking precision.

Owner:合肥中科智驰科技有限公司

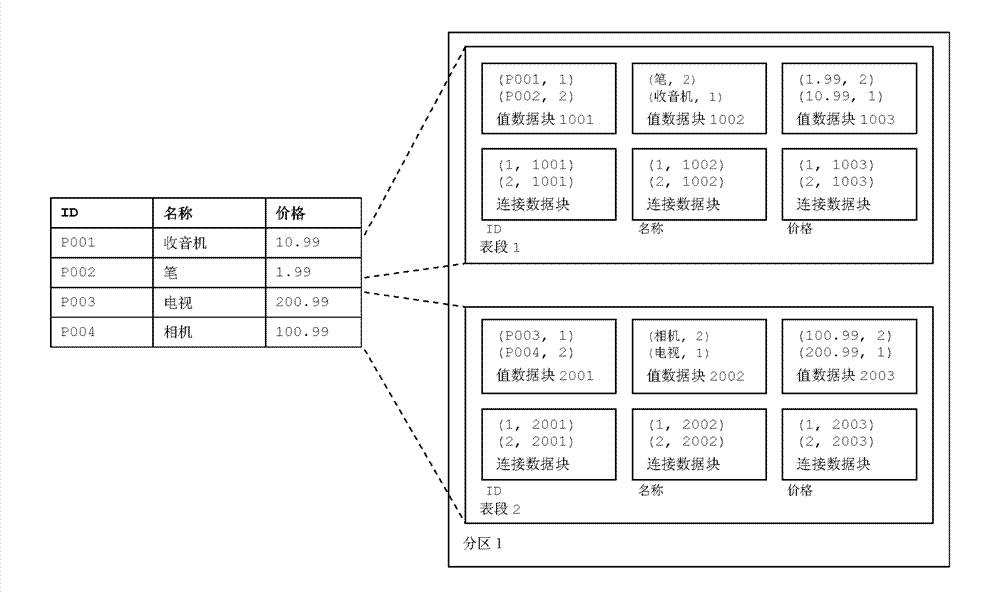

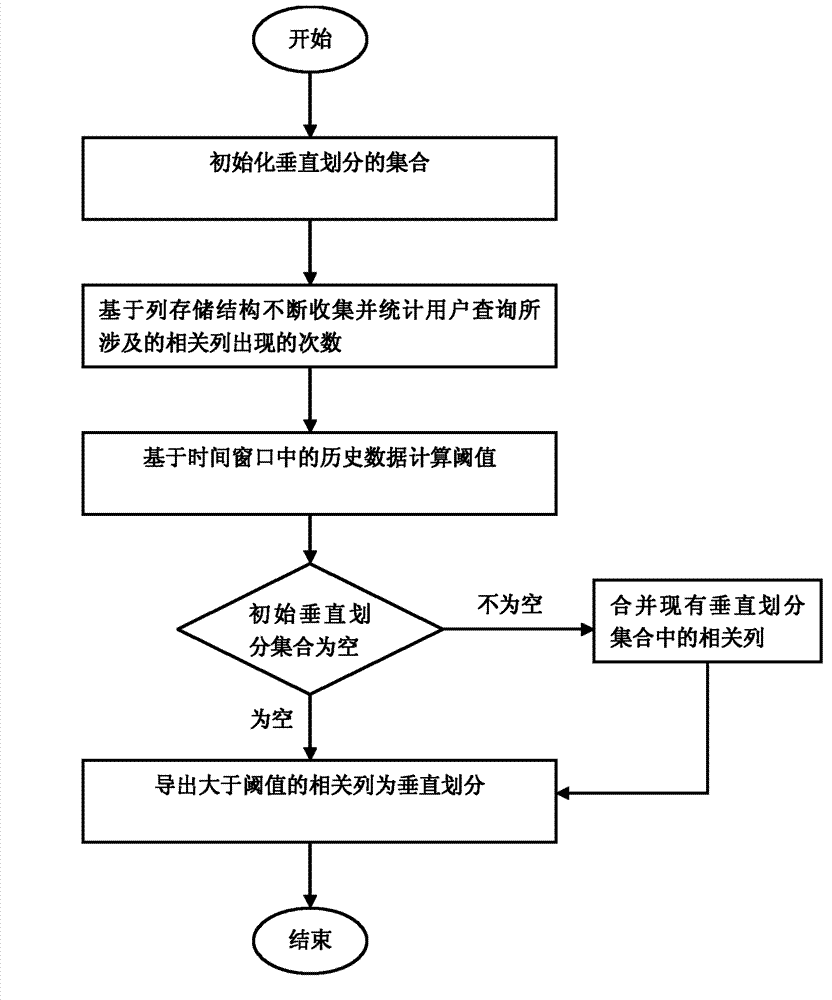

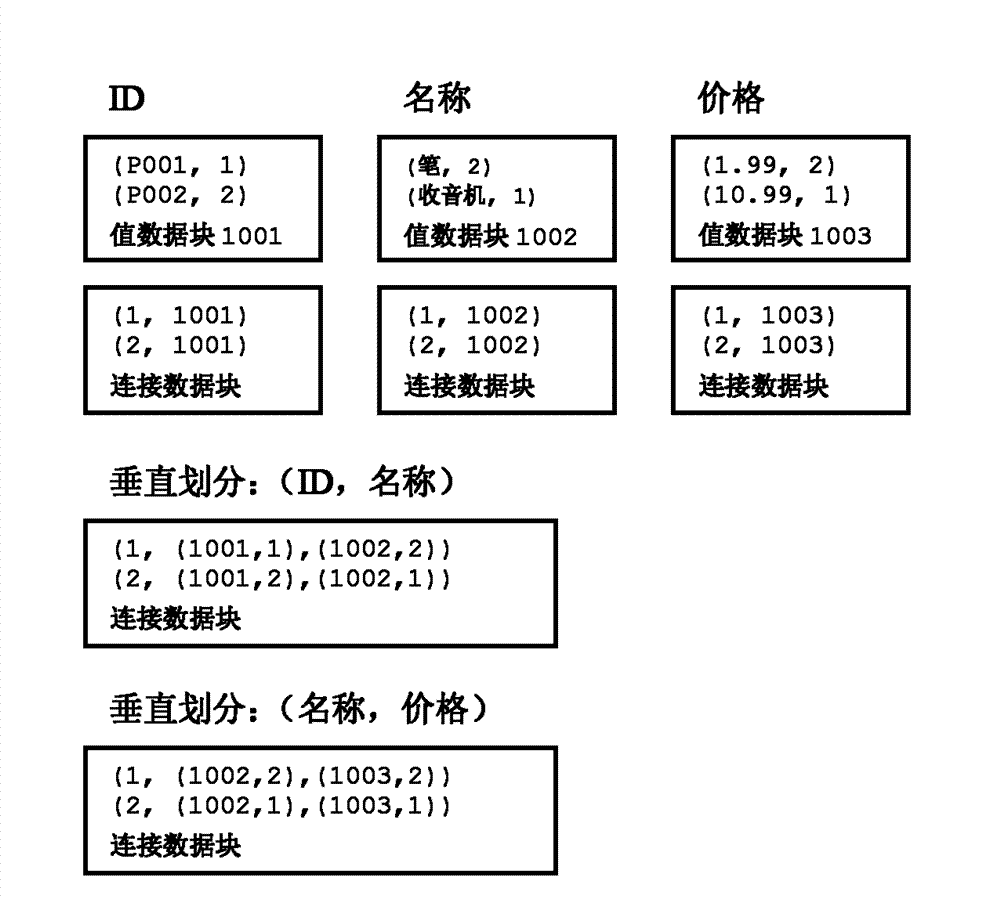

Method for realizing self-adaptive vertical divided relational database and system thereof

ActiveCN102156714BSpeed up readingRealize automatic tuningSpecial data processing applicationsExtensibilityRelational database

The invention discloses a method for realizing a self-adaptive vertical divided relational database, belonging to the field of a relational database, comprising the following steps of: S1, for a list, continuously collecting and counting correlation column occurring times related by user inquiring based on a column storage structure, calculating thresholds of the correlation column occurring times based on the historic data in the predetermined time window, educing the correlation columns greater than the thresholds for vertically dividing and obtaining the vertically divided correlation column sets; S2, creating the connection data based on the vertically divided correlation column sets; and S3, based on the vertically divided correlation column sets, adopting a predetermined policy for distributing different correlation columns of the list to different segments to realize parallel execution of inquiry. The invention can improve the rationality of the storage structure and realize parallel inquiry and improve the expandability.

Owner:TSINGHUA UNIV +1

Neural-network self-correcting control method of permanent magnet synchronous motor speed loop

ActiveCN102497156BAdaptableSimple structureElectronic commutation motor controlVector control systemsPower flowLoad torque

The invention discloses a neural-network self-correcting control method of a permanent magnet synchronous motor speed loop. The method is characterized by: taking a current loop and a motor as generalized objects; firstly, collecting information, such as a rotating speed, a current and the like; using an adaptive linear time-delay neural network to carry out off-line parameter identification to the motor; then, taking a weight obtained through off-line learning as an initial value of on-line learning; finally, carrying out on-line parameter identification to the system, calculating a load torque of the motor according to the identified parameter; designing a neural-network self-correcting control law according to the obtained parameter value and a load disturbance value, adjusting the network weight on line according to an error between a controlled object and an identification model, and then setting the parameter of the neural-network self-correcting controller on line so as to realize online adjustment of the controller parameter. Uncertainty of the system and influence brought by the external disturbance can be eliminated. Dynamic performance and an anti-disturbance ability of a servo system can be improved.

Owner:SOUTHEAST UNIV +1

Relay feedback based AC servo system automatic setting method

InactiveCN101552589BRealize automatic tuningMotor parameters estimation/adaptationMovement controlMotion control

A relay feedback based AC servo system automatic setting method belonging to the motion control technology field comprises a speed ring setting process and a position ring setting process. The method comprises the following steps: setting the parameters of saturated relay with delay; bringing the relay identification link into the closed speed ring (or position ring) to cause the system to establish a limit ring quickly; evaluating the system delay and the limit oscillation period parameter; identifying the AC servo system model; and setting the PID control parameter automatically by the PID parameter setting principle such as pole assignment method and amplitude phase margin method according to the identified model parameters; By combining the saturated relay feedback and he PID parametersetting principle such as ITAE method and amplitude phase margin method, the invention can accomplish the parameter automatic setting to the controller of AC servo motor.

Owner:SHANGHAI JIAO TONG UNIV

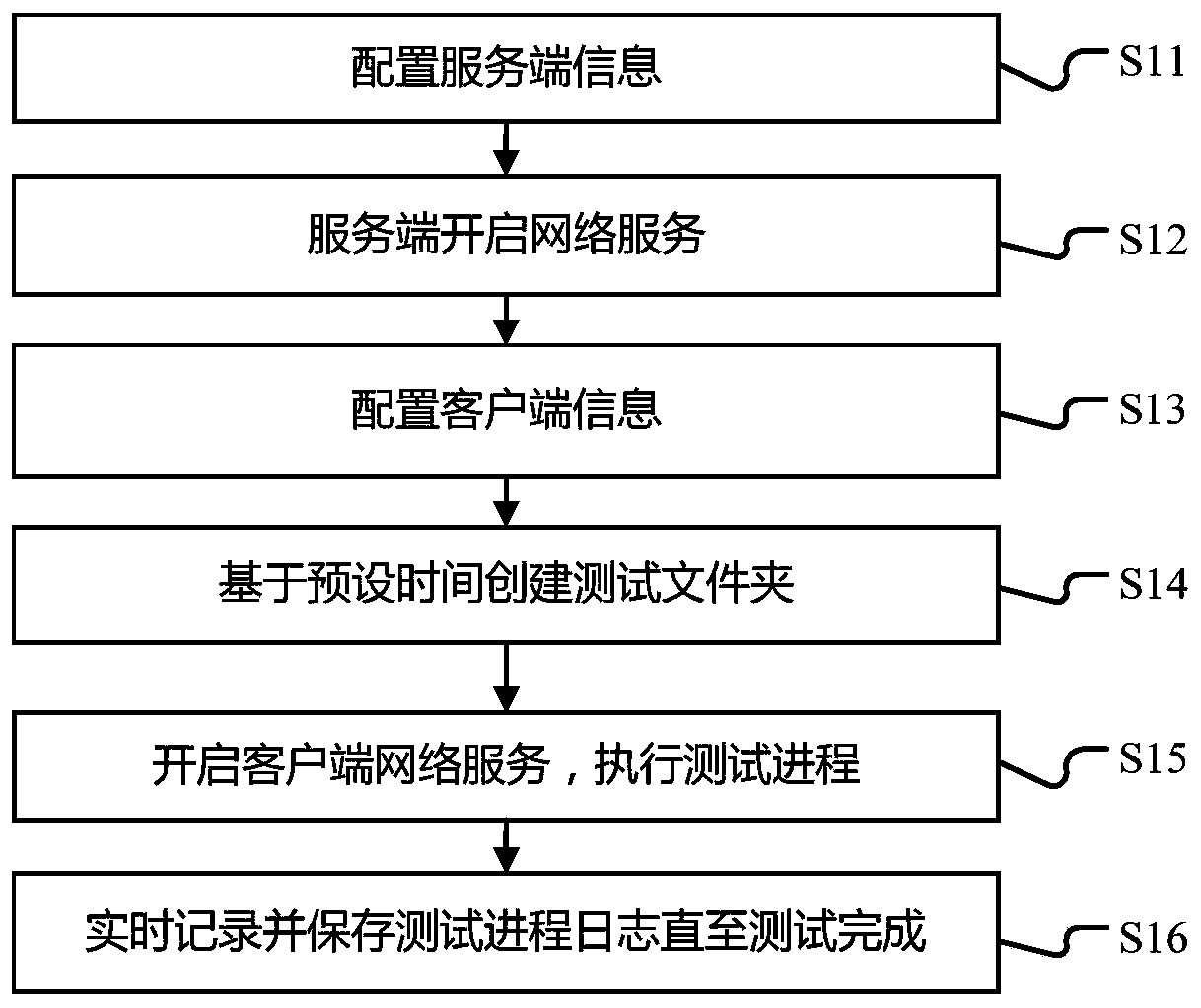

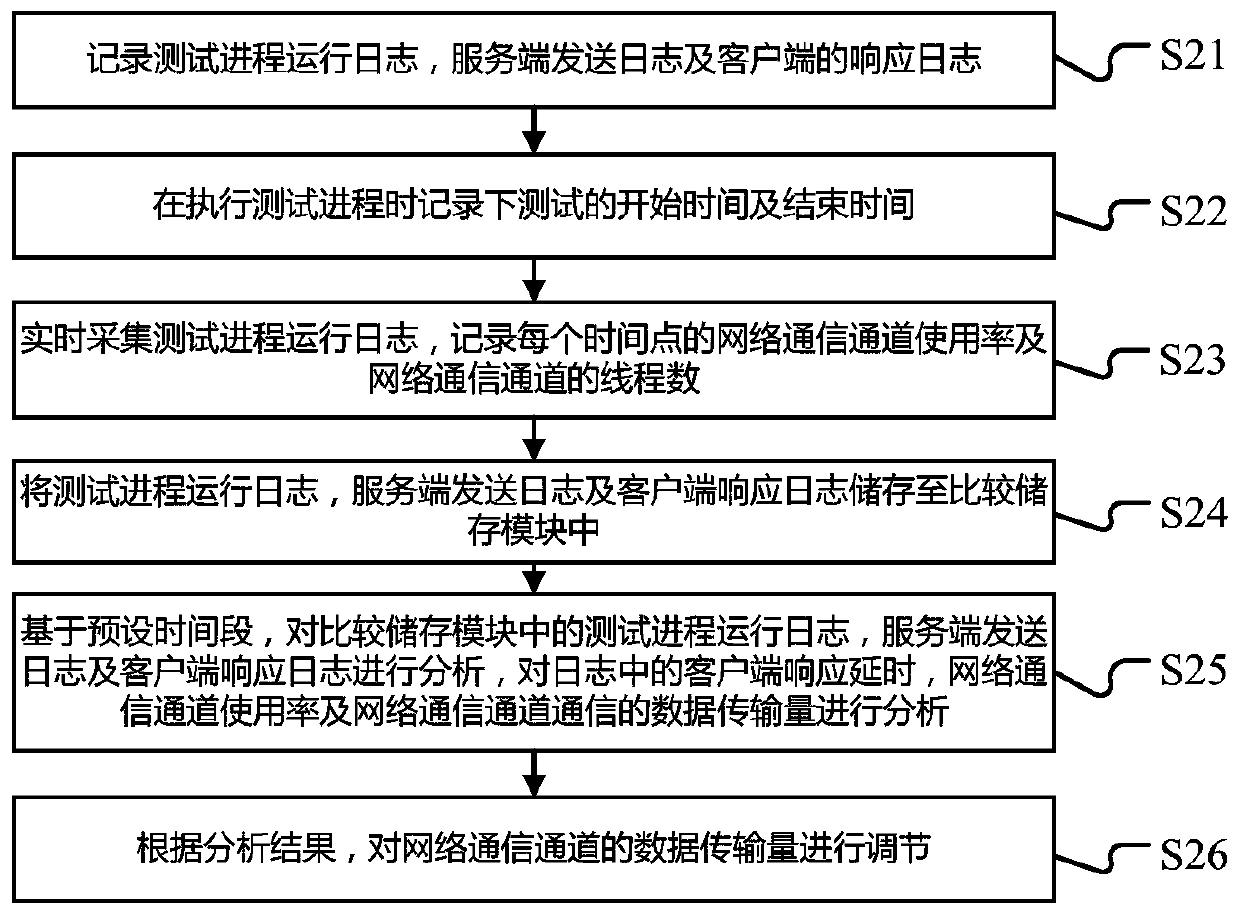

Automatic optimization and network pressure test method and system

InactiveCN110995491ARealize automatic tuningNo complex manual operation requiredData switching networksServer logNetwork service

The invention provides an automatic optimization and network pressure test method and system. The method comprises the following steps: configuring server information; the server starts network service; configuring client information; creating a test folder based on preset time; starting a client network service, and executing a test process; and recording and storing the test process log in realtime until the test is finished. The client automatically creates an appropriate test result directory, automatically performs testing according to a unified standard, and stores a test result; and when the specified test is often finished, the script automatically stores information such as the current test log, the server log and the client log in the created test folder without complex manual operation. In the testing process, the situation that the bandwidth of network testing does not reach the highest value due to omission of steps is avoided. And when overload occurs in the test process, dynamic adjustment can be performed, so that the network can reach a balanced range, and a reference is provided for later adjustment of the communication network.

Owner:SUZHOU LANGCHAO INTELLIGENT TECH CO LTD

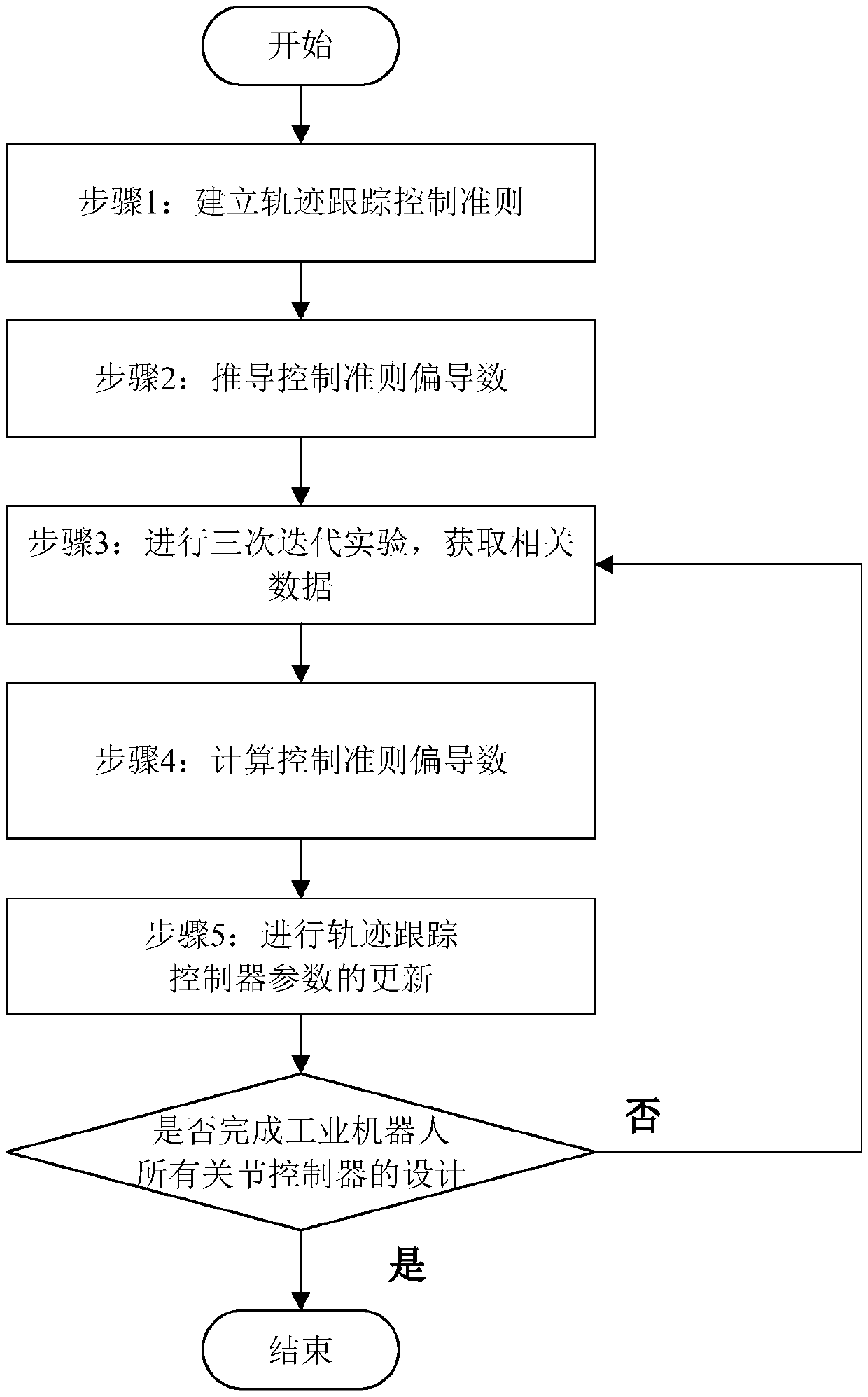

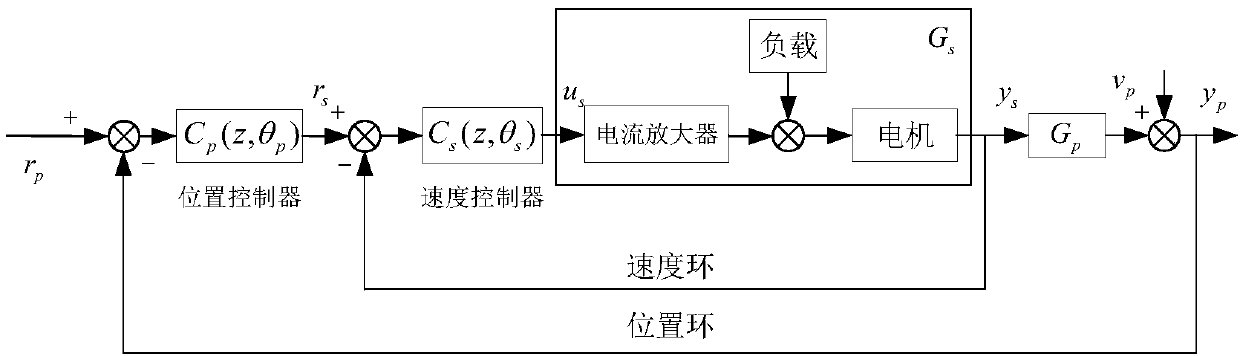

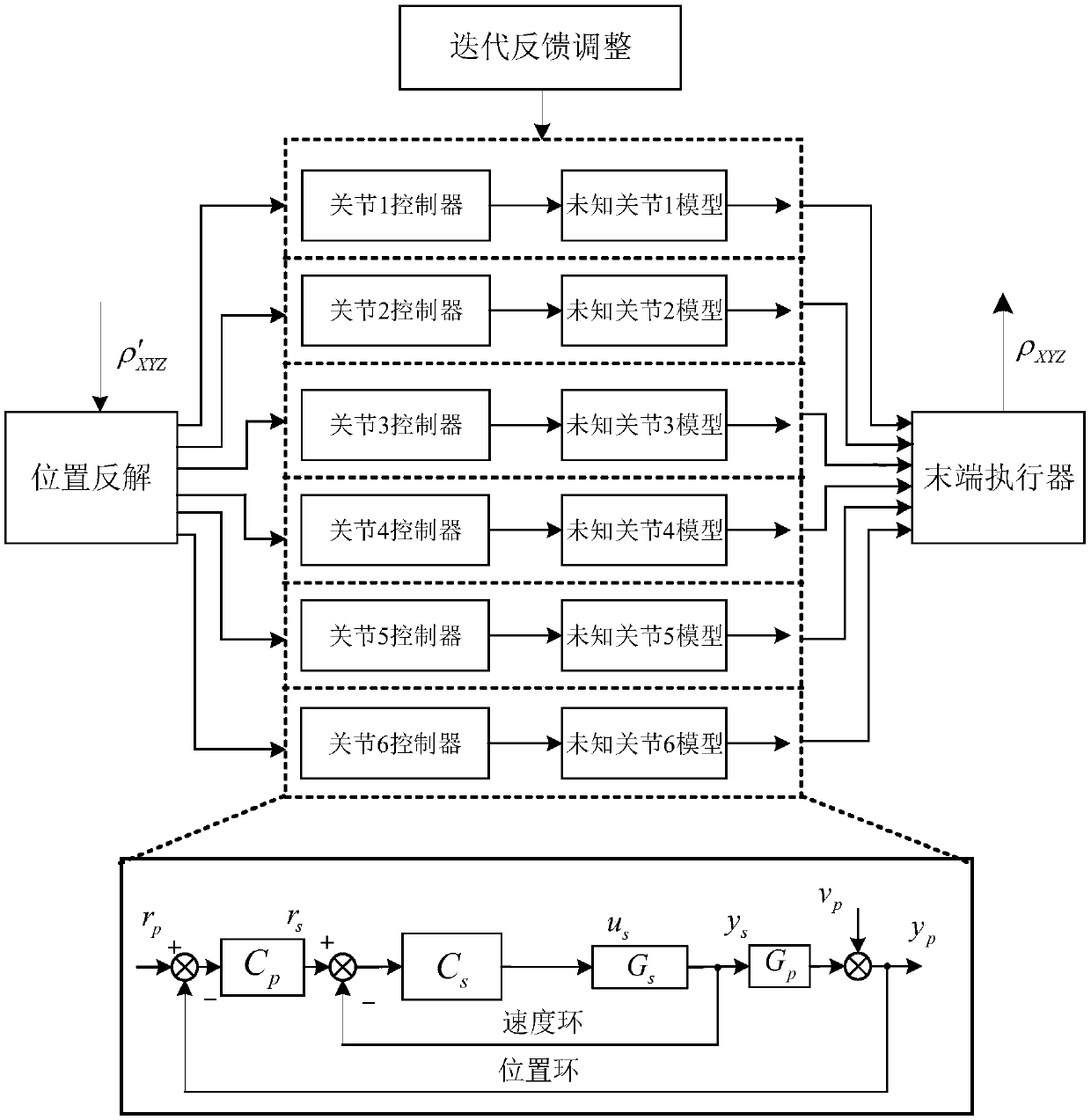

Industrial robot based on iterative feedback adjustment and trajectory tracking control method thereof

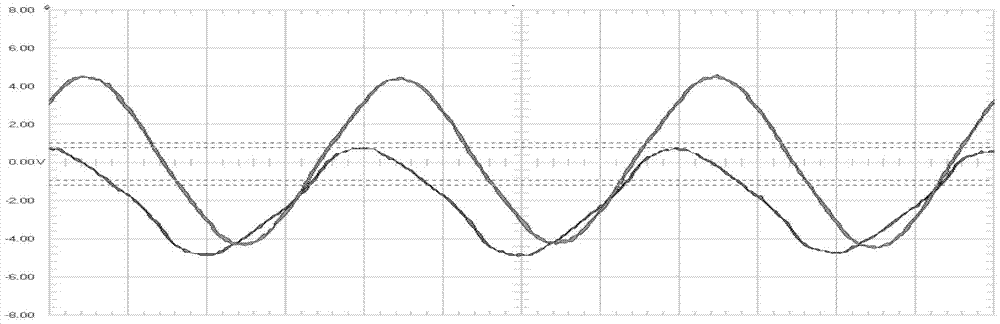

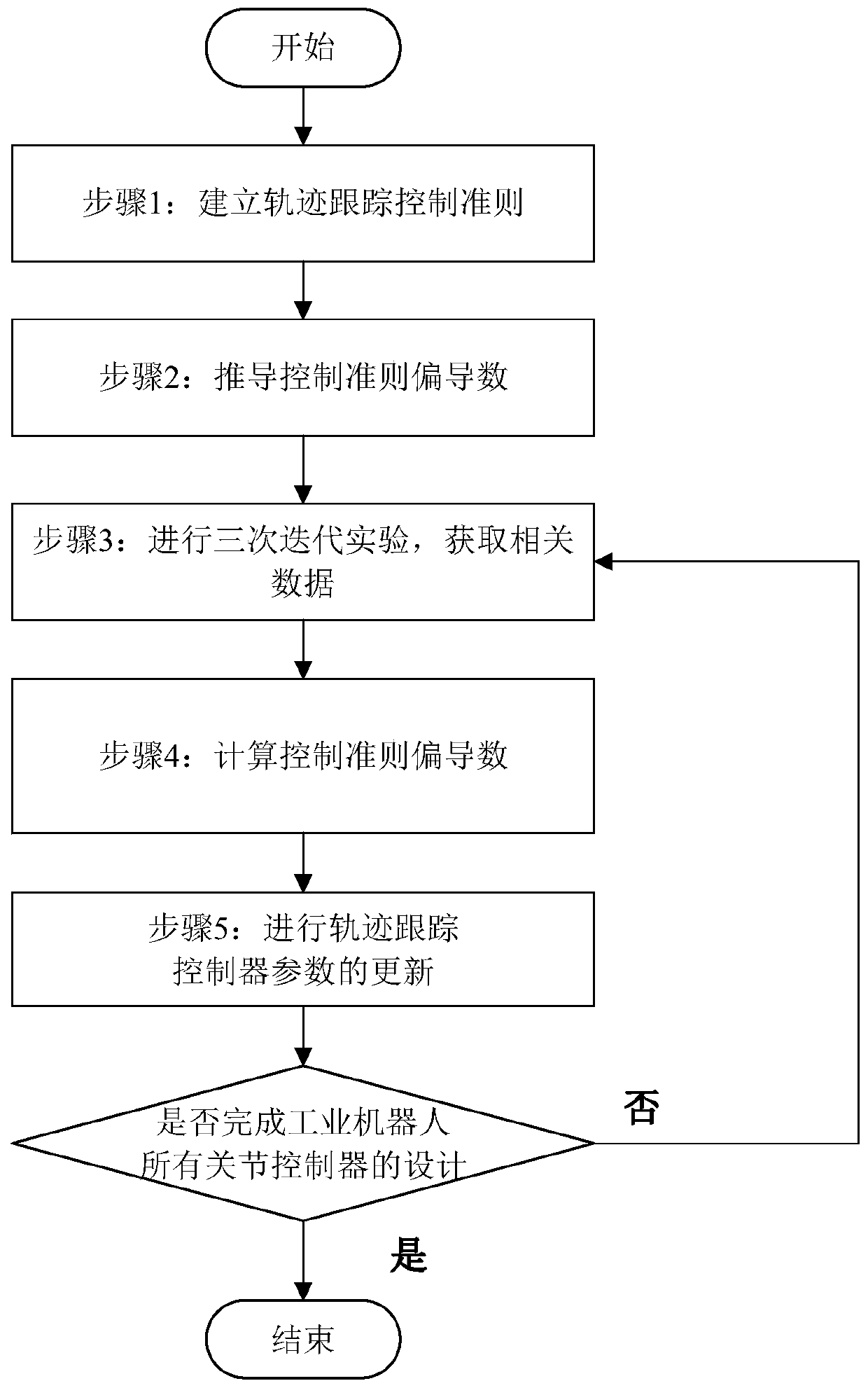

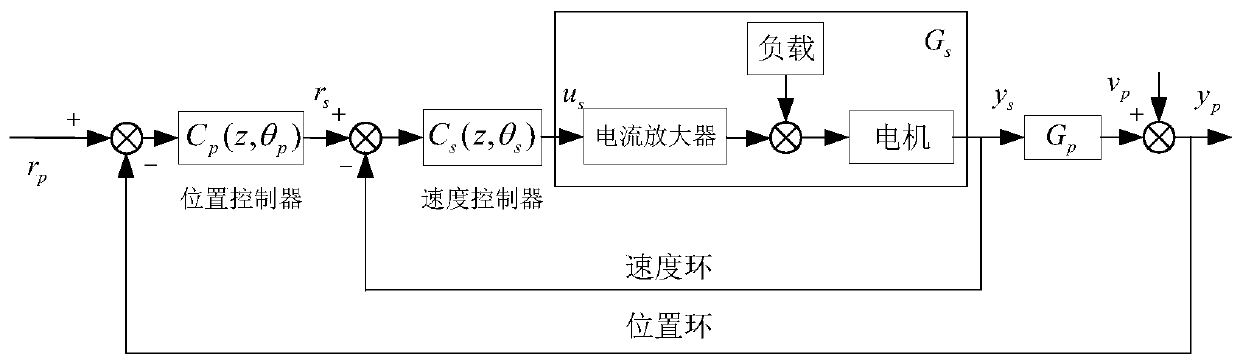

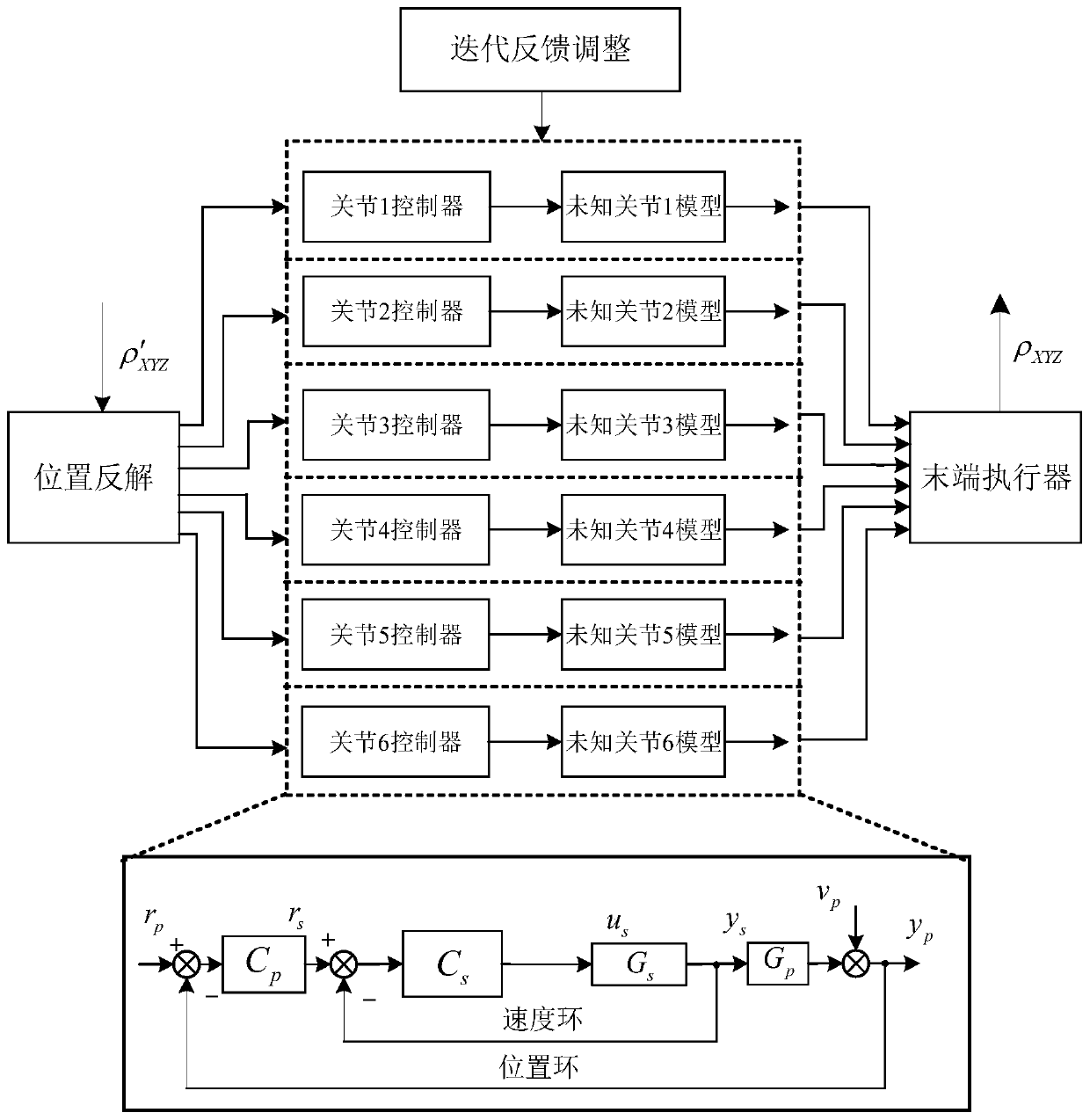

InactiveCN109669348AImprove control effectEliminate the effects of noise interferenceAdaptive controlSelf adaptiveVelocity controller

The invention discloses an industrial robot based on iterative feedback adjustment and a trajectory tracking control method thereof, and belongs to the field of industrial robot control. The method combines the limitation of the amplitude of a control input signal and trajectory tracking errors, establishes a trajectory tracking control criterion, derives to obtain a partial derivative of the control criterion relative to a speed controller and a position controller, then designs three iterative experiments and uses the collected data to complete the estimation of the information of the partial derivative of the control criterion, and realizes the update and correction of trajectory tracking controller parameters of joint drive systems. Compared with the prior art, the trajectory trackingcontrol method is a model-free adaptive control method which is not affected by unmodeled dynamics and modeling errors, the effect of noise disturbance by a method of repeatedly obtaining data by iteration is eliminated, and position following errors in an iteration domain are combined to adaptively update the trajectory tracking controller parameters of a correction system to ensure that the following control performance of the system is optimal.

Owner:HUAZHONG UNIV OF SCI & TECH

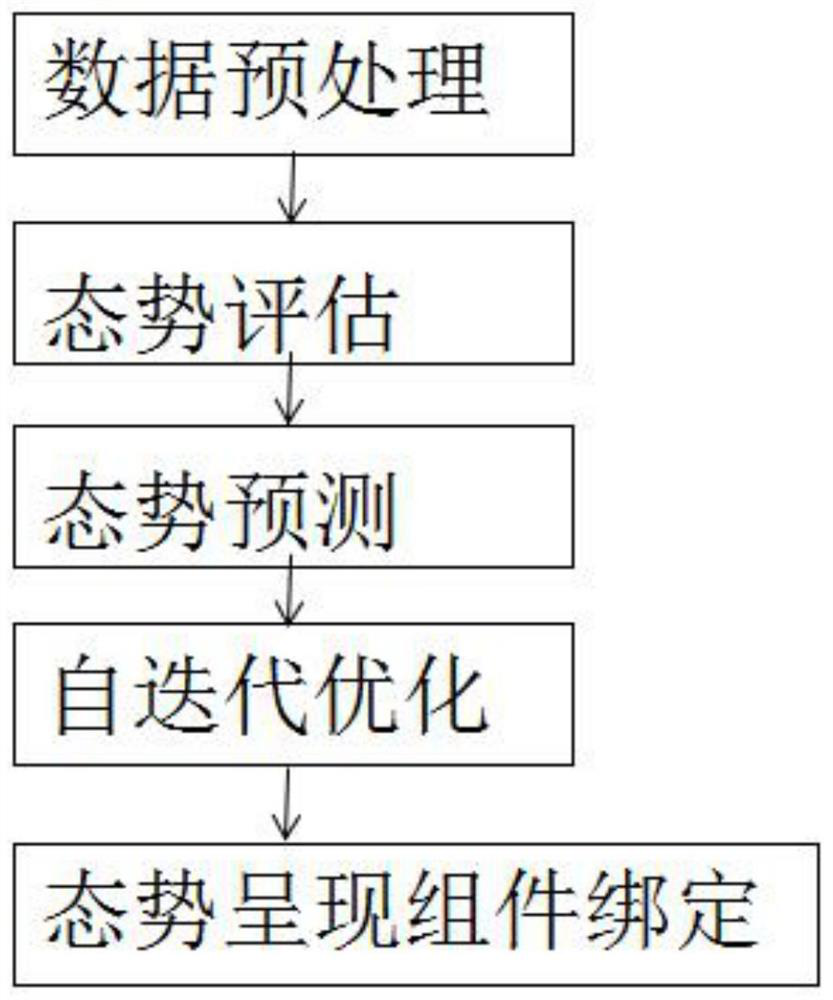

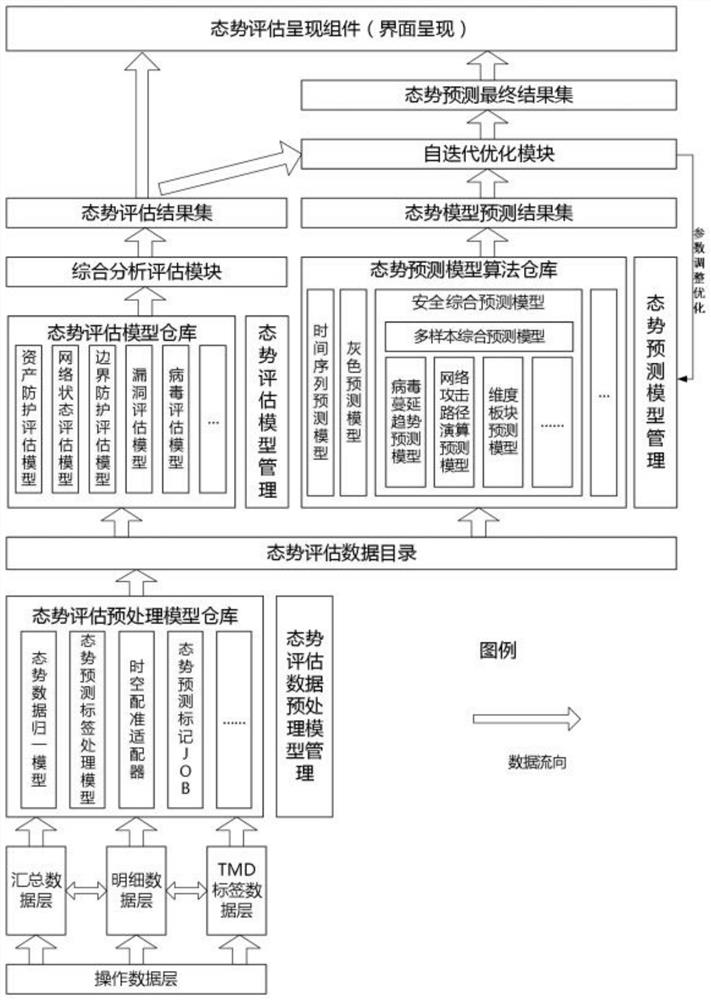

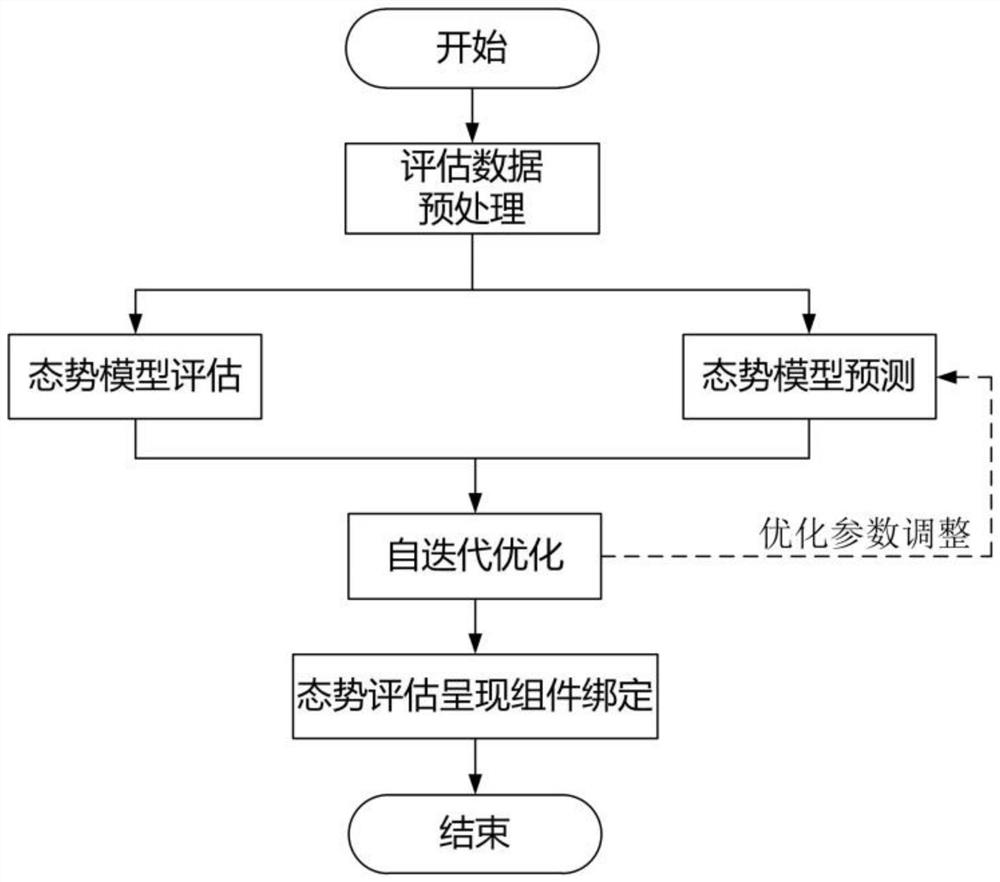

Self-iteration situation prediction method and system based on data center

PendingCN114118563AImprove operational efficiencyEfficient use ofForecastingResourcesPrediction algorithmsData center

The invention discloses a self-iteration situation prediction method and system based on a data center station, and the method comprises the following steps: S1, data preprocessing; s2, situation assessment; s3, situation prediction; s4, carrying out self-iteration optimization; and S5, binding the situation presentation component. According to the method, the following problems in the prior art are solved: aiming at original security data with wide sources, complicated types and heterogeneous formats, a single fixed situation evaluation and prediction algorithm is difficult to accurately analyze a situation development trend in massive multivariate heterogeneous network security data; the efficiency and efficiency of network security situation assessment and prediction are low.

Owner:NO 30 INST OF CHINA ELECTRONIC TECH GRP CORP

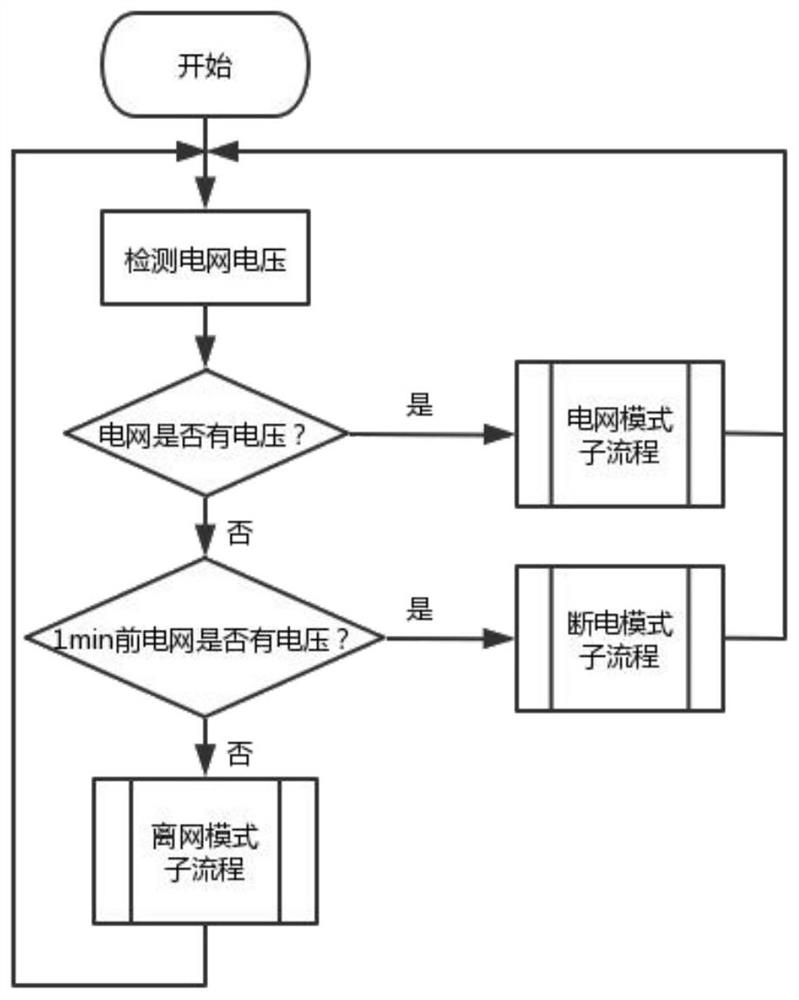

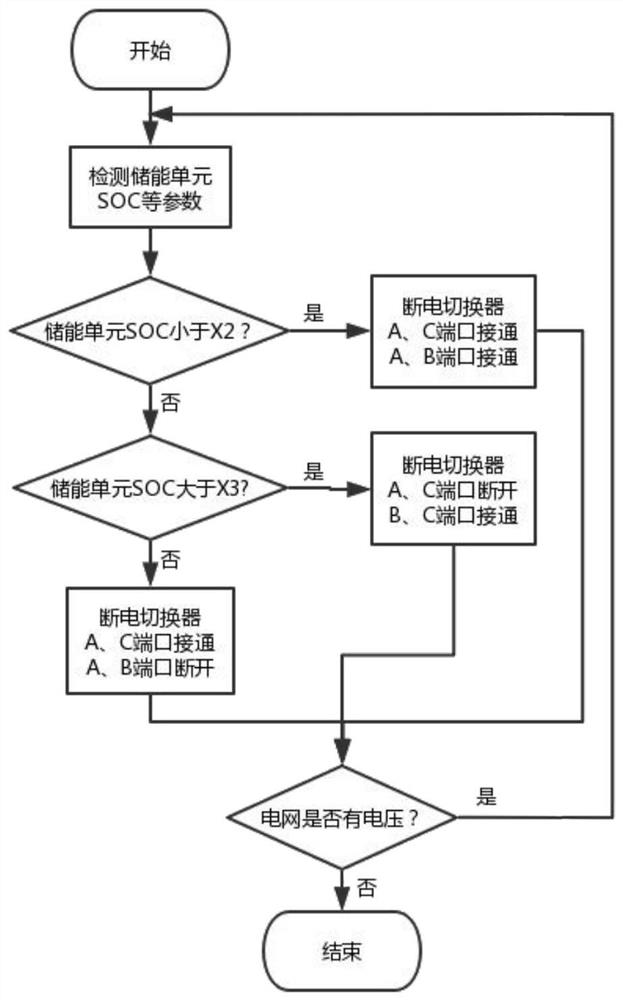

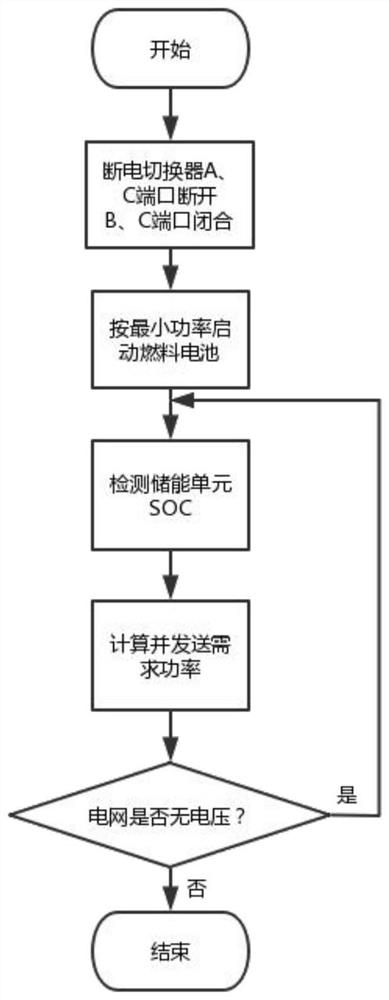

Control method of hydrogen fuel cell emergency power supply system

ActiveCN113193645AGuaranteed to match each otherRealize automatic tuningEmergency power supply arrangementsTerminal voltageHydrogen fuel cell

The invention discloses a control method of a hydrogen fuel cell emergency power supply system, and the method comprises the following steps: judging a power grid voltage state according to a power grid input end voltage value, and entering a power grid mode if the power grid has a voltage; carrying out the power supply switching according to the SOC value of the energy storage unit in the power grid mode; if the power grid has no voltage, further judging whether the voltage exists in the previous step time, and if the voltage exists before the previous step time, entering a power-off mode; in the power-off mode, carrying out the power supply adjustment through the power of the hydrogen fuel cell and the SOC value of the energy storage unit; if no voltage exists before the previous step time, entering an off-grid mode; in the off-grid mode, carrying out the power supply adjustment according to the SOC value of the energy storage unit, the load power and the hydrogen fuel cell power. According to the invention, electric energy is rapidly provided when the power grid is powered off, the control precision is high, the threshold SOC values of different types of energy storage units can be automatically set, and the control performance is better; and mutual matching of operation and environment of the hydrogen fuel cell emergency power supply system can be ensured.

Owner:四川荣创新能动力系统有限公司

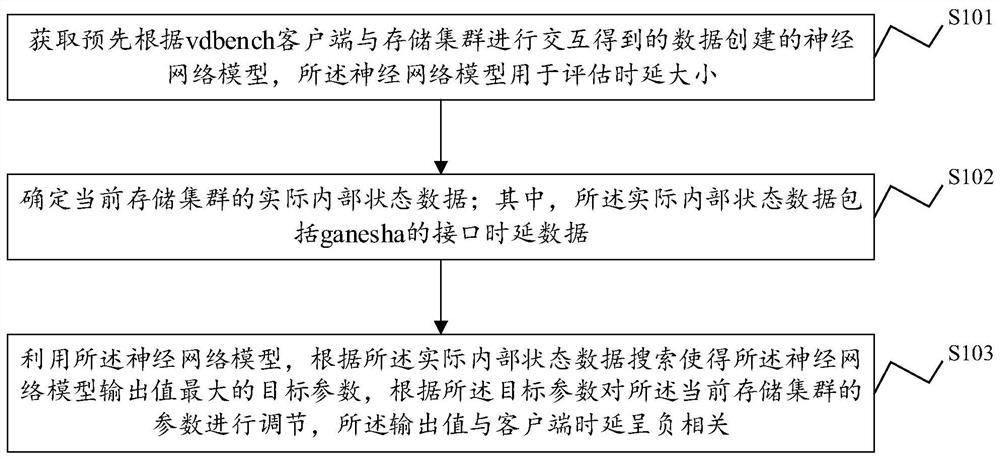

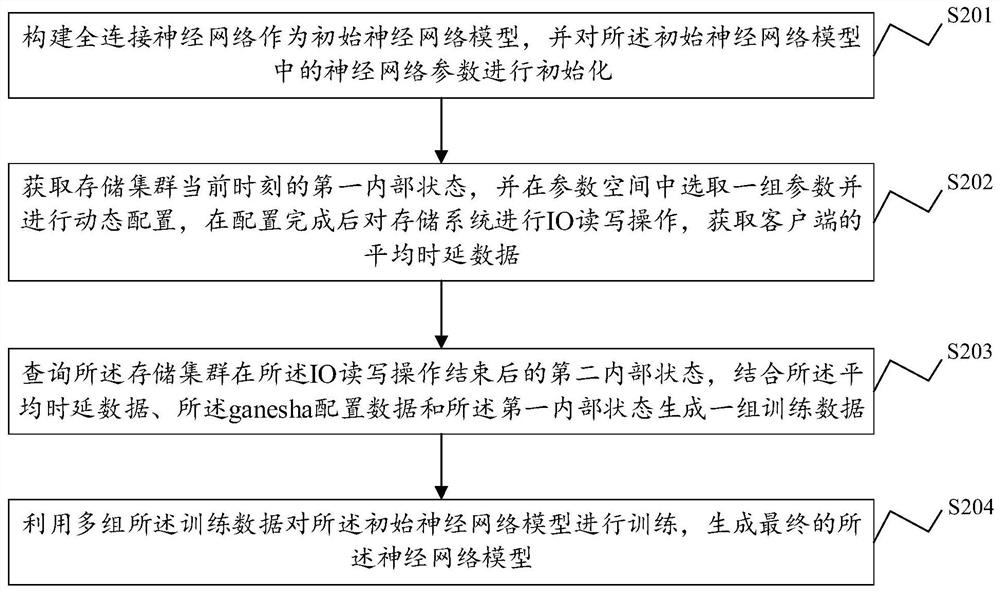

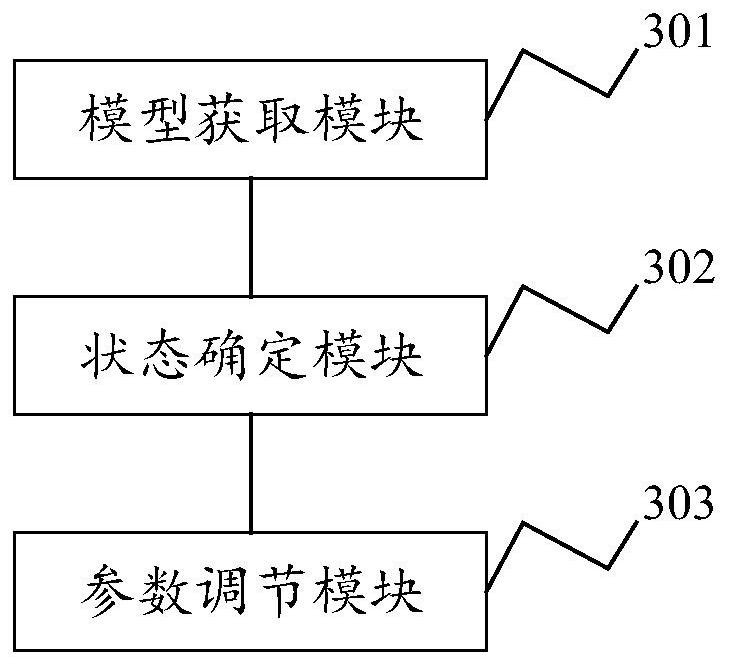

Distributed storage system parameter adjusting method and device, electronic equipment and medium

PendingCN112162966ARealize automatic tuningReduce labor costsDigital data information retrievalNeural architecturesData packEngineering

The invention discloses a distributed storage system parameter adjusting method and device, equipment and a medium. The distributed storage system parameter adjusting method comprises the steps of: acquiring a neural network model which is created in advance according to data obtained by interaction between a vdbench client and a storage cluster and is used for evaluating a time delay size; determining actual internal state data of the current storage cluster, wherein the actual internal state data comprises interface time delay data of ganesha; and searching a target parameter enabling an output value to be maximum according to the actual internal state data by utilizing the neural network model, and adjusting parameters of the current storage cluster according to the target parameter, wherein the output value is in negative correlation with the time delay of a client. According to the distributed storage system parameter adjusting method and the device, the neural network model for evaluating the time delay can be created, the actual internal state data of the storage cluster can be obtained, the target parameter capable of maximizing the output value can be searched based on thecreated neural network model, the target parameter capable of minimizing the time delay can be obtained so as to adjust and optimize the storage cluster, and the automatic adjustment and optimizationof the storage cluster can be realized.

Owner:北京浪潮数据技术有限公司

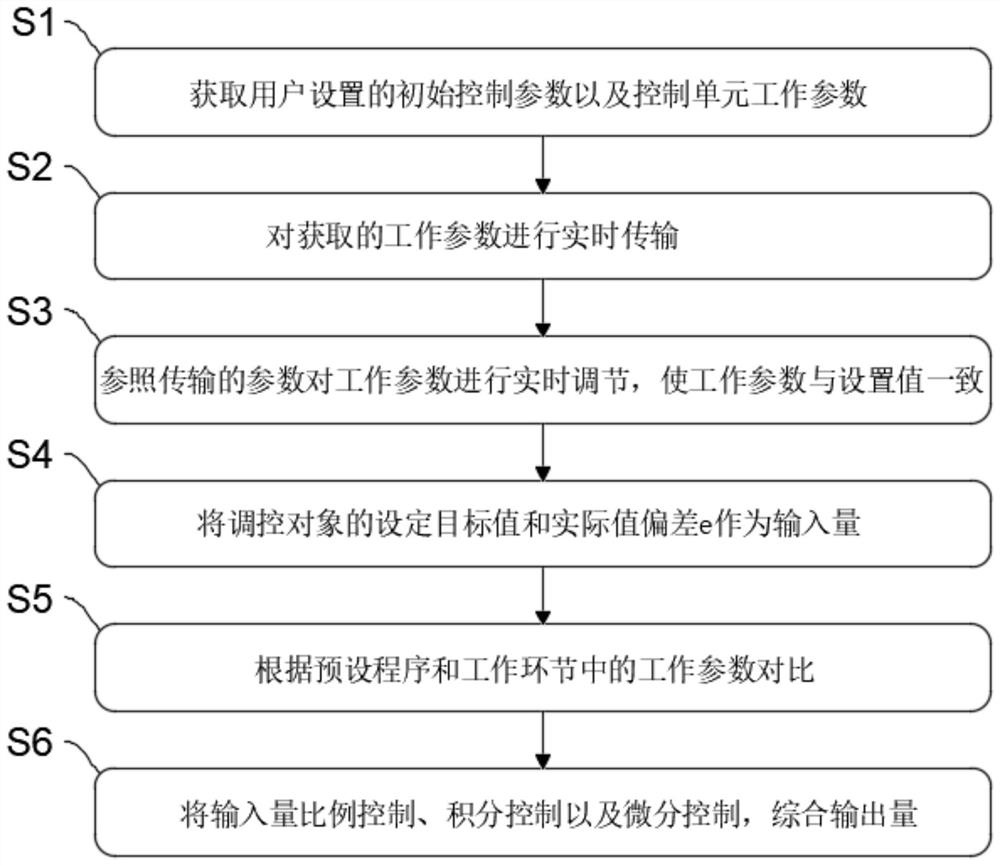

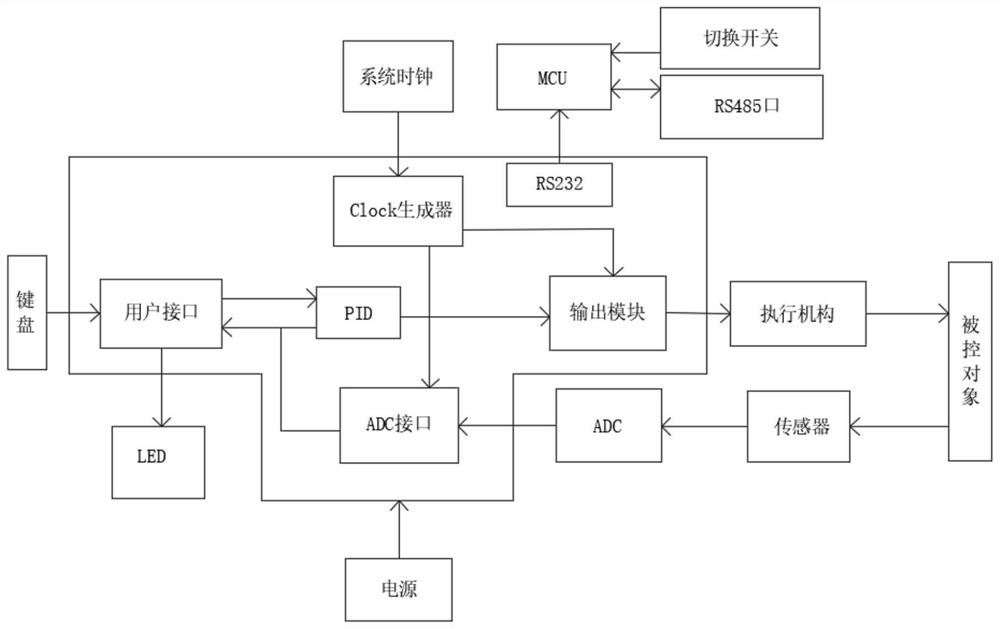

Intelligent PID control device

PendingCN114706290ARealize automatic tuningHigh control precisionControllers with particular characteristicsControl modeSetpoint

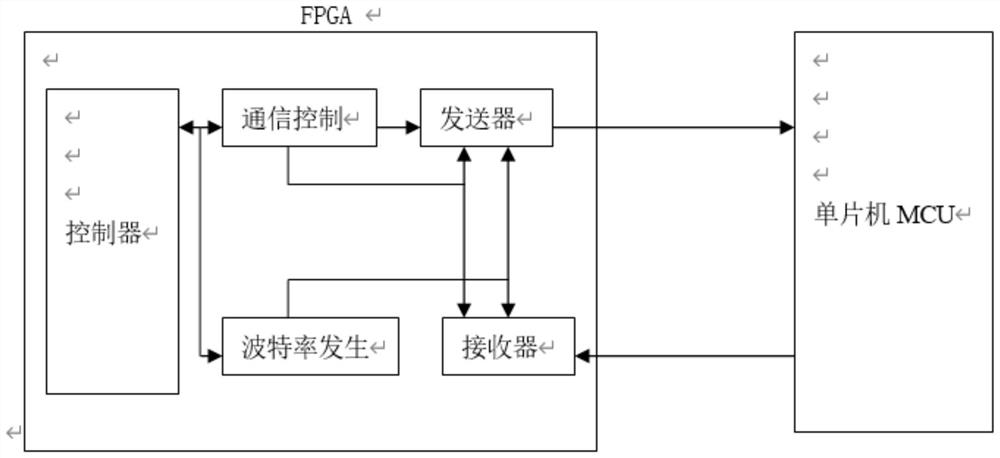

The invention discloses an intelligent PID (Proportion Integration Differentiation) control method. The method comprises the following steps: acquiring initial control parameters set by a user and working parameters of a control unit; the acquired working parameters are transmitted in real time; the working parameters are correspondingly adjusted in real time according to the working parameters transmitted in real time, so that the working parameters are consistent with the set values; taking a set target value and an actual value deviation e of the regulation and control parameter object as an input quantity; comparing working parameters in the working links according to a preset program; the input quantity is subjected to proportional control, integral control and differential control, and the output quantity is synthesized; according to the intelligent PID control device, the single-chip microcomputer serves as a control unit, PID control is achieved through an intelligent algorithm, automatic PID parameter setting and automatic combination of proportional differential (PD), proportional integral (PI) and PID control modes can be achieved through the intelligent PID control device, and the intelligent PID control device is high in control precision, convenient and rapid to use and high in execution efficiency.

Owner:HUANENG QUFU THERMAL POWER CO LTD

Adjusting and optimizing method and device for MPI parameters, storage medium and electronic equipment

PendingCN113760766ARealize automatic tuningHigh precisionCharacter and pattern recognitionSoftware testing/debuggingProcess engineeringIndustrial engineering

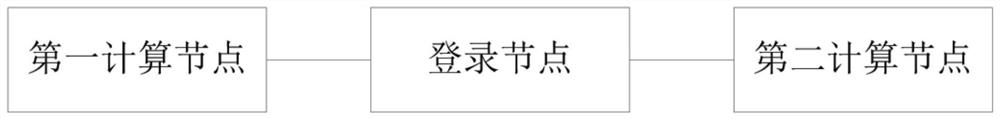

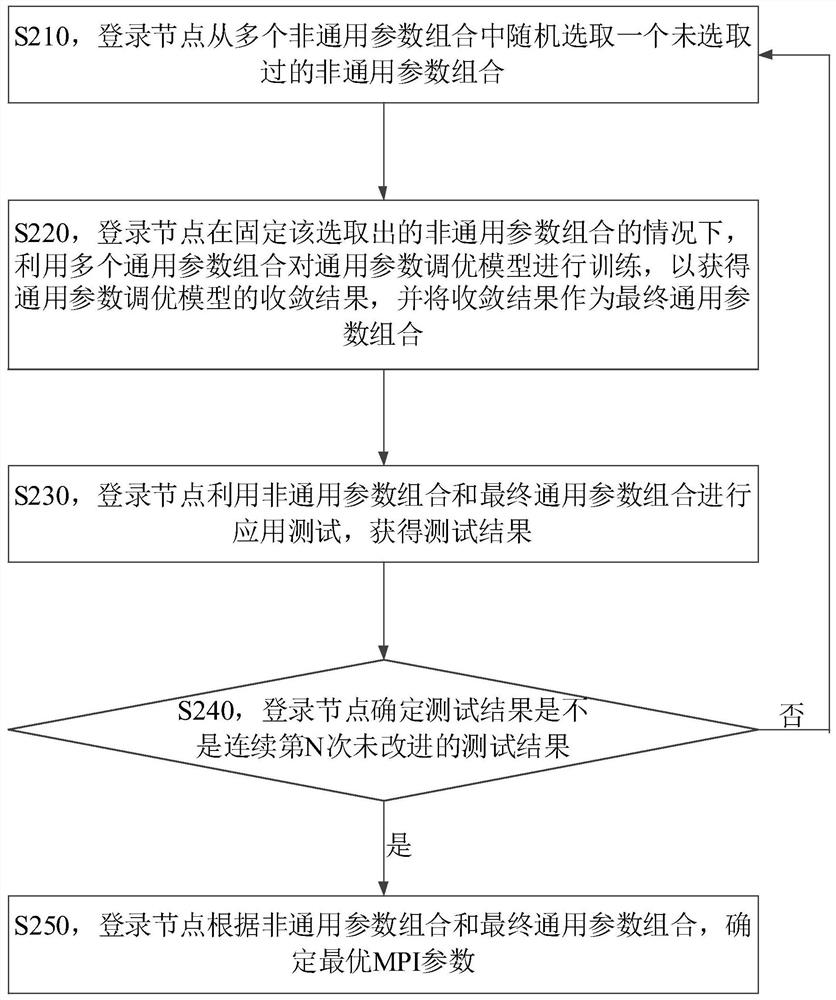

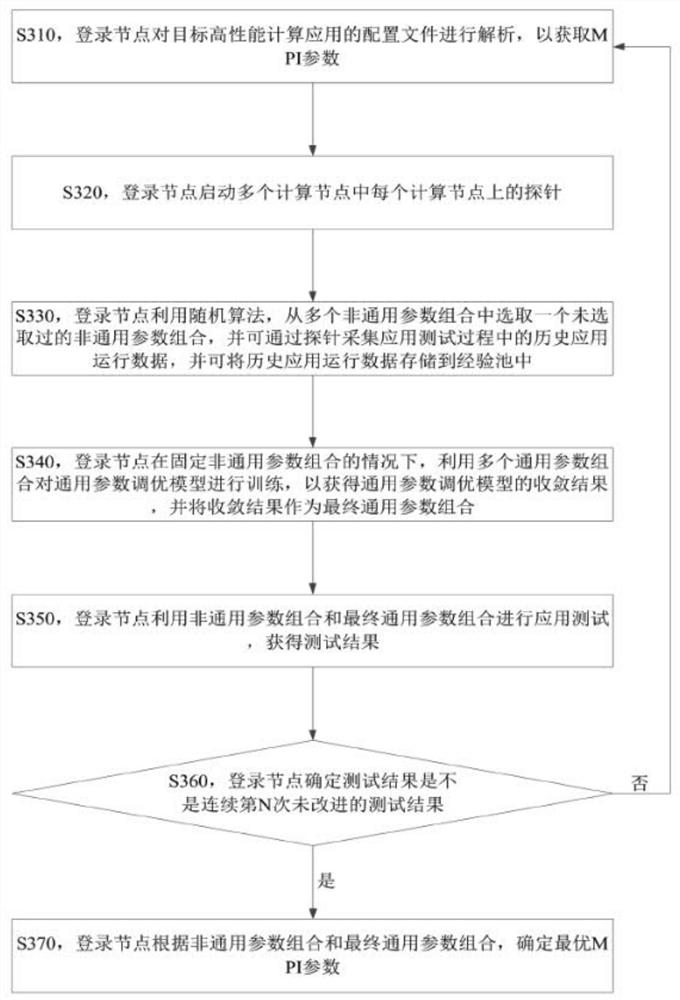

The embodiment of the invention provides an adjusting and optimizing method and device for MPI parameters, a storage medium and electronic equipment. The adjusting and optimizing method comprises the steps of randomly selecting an unselected non-universal parameter combination from multiple non-universal parameter combinations; under the condition that the non-general parameter combinations are fixed, training the general parameter tuning model by using the plurality of general parameter combinations to obtain a convergence result of the general parameter tuning model, and taking the convergence result as a final general parameter combination; using the non-general parameter combination and the final general parameter combination to perform application test to obtain a test result; and if determining that the test result is a continuous Nth unimproved test result, determining an optimal MPI parameter according to the non-general parameter combination and the final general parameter combination. By means of the above technical scheme, the embodiment of the invention can improve the tuning efficiency.

Owner:DAWNING INFORMATION IND BEIJING

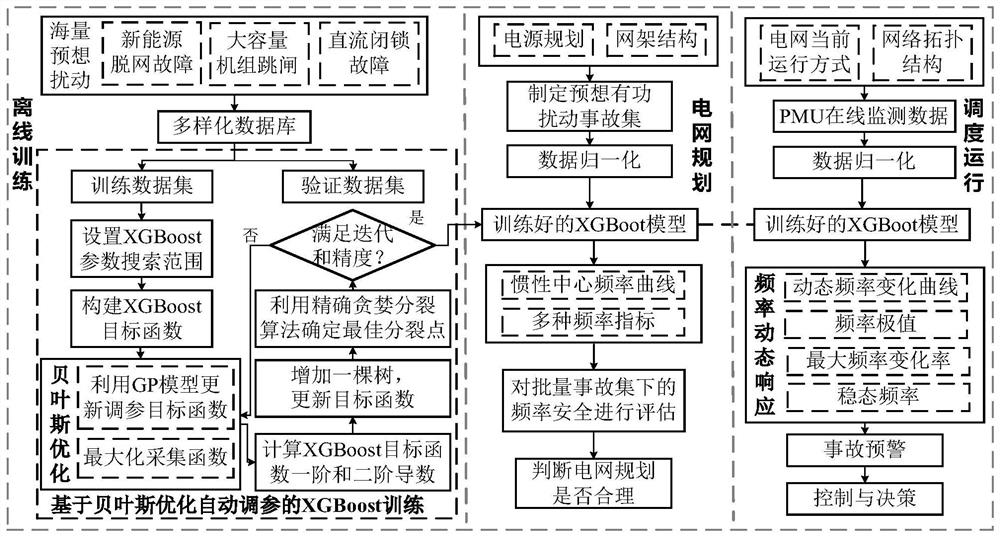

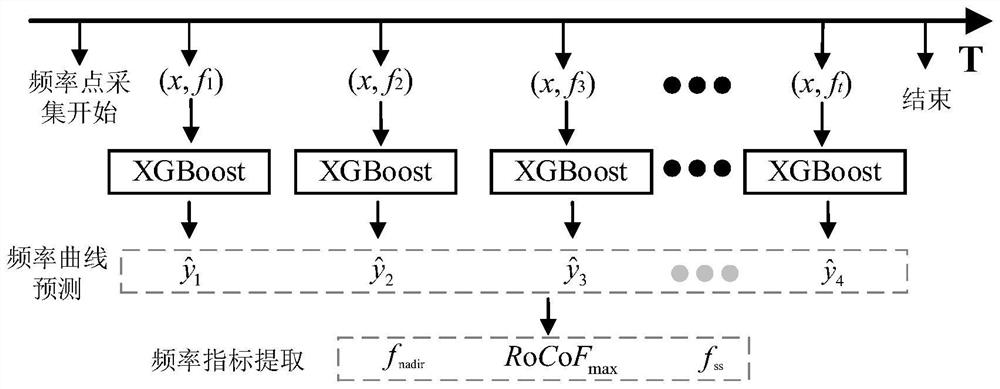

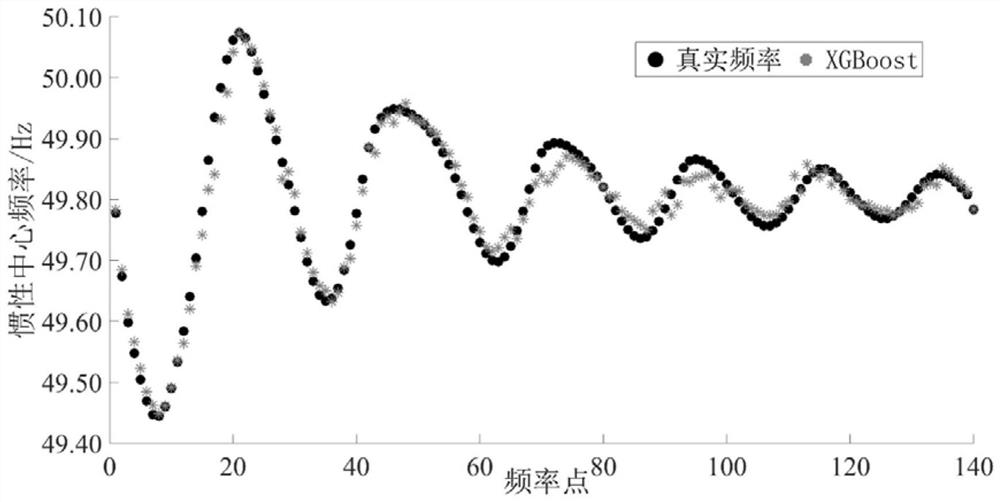

Power system dynamic frequency response curve prediction method and system based on XGBoost

PendingCN114139809ARealize online predictionPredictableMathematical modelsEnsemble learningData setEngineering

The invention provides an XGBoost-based power system dynamic frequency response curve prediction method and system, and the method comprises the steps: firstly, obtaining a diversified database based on a simulation result of a massive anticipated fault scene, randomly dividing the diversified database into a training data set and a test data set, and carrying out the normalization processing of the two data sets; secondly, constructing a frequency response curve predictor based on an XGBoost integrated learning model, and determining an optimal hyper-parameter by using a Bayesian optimization model; and finally, carrying out iterative learning on the frequency response curve predictor by utilizing the training data set, and carrying out online evaluation on the dynamic frequency response of the system under a given expected fault or a current operation state by utilizing the trained frequency response curve predictor. According to the XGBoost model disclosed by the invention, the dependency on a sample is reduced; the automatic tuning of hyper-parameters in the XGBoost model is realized through Bayesian optimization, and the prediction of the whole frequency response curve under the disturbance event is realized.

Owner:ECONOMIC TECH RES INST OF STATE GRID HENAN ELECTRIC POWER +2

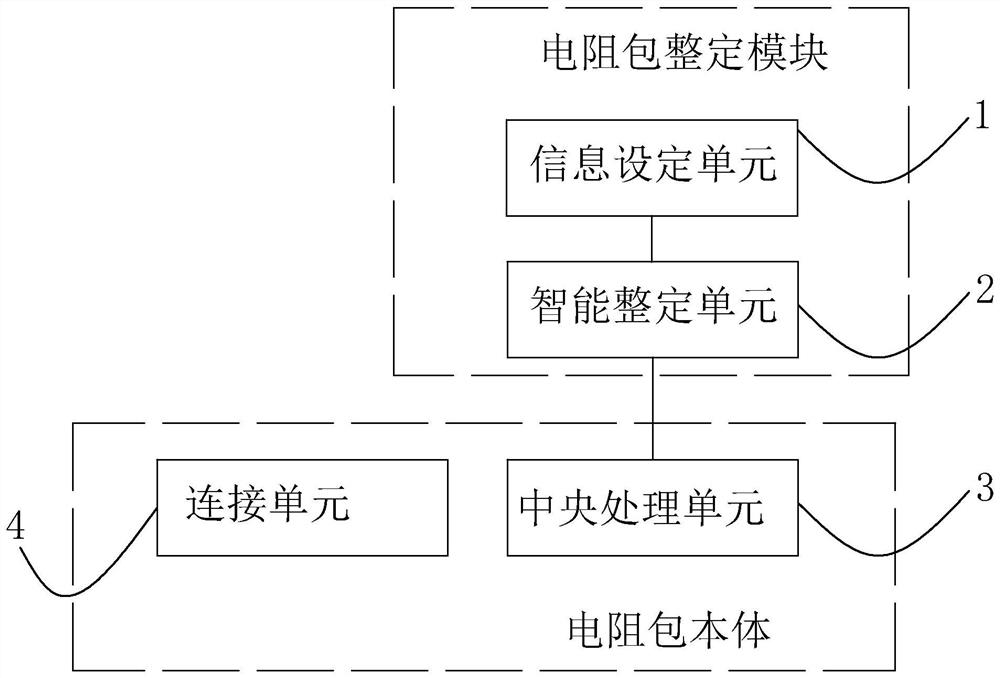

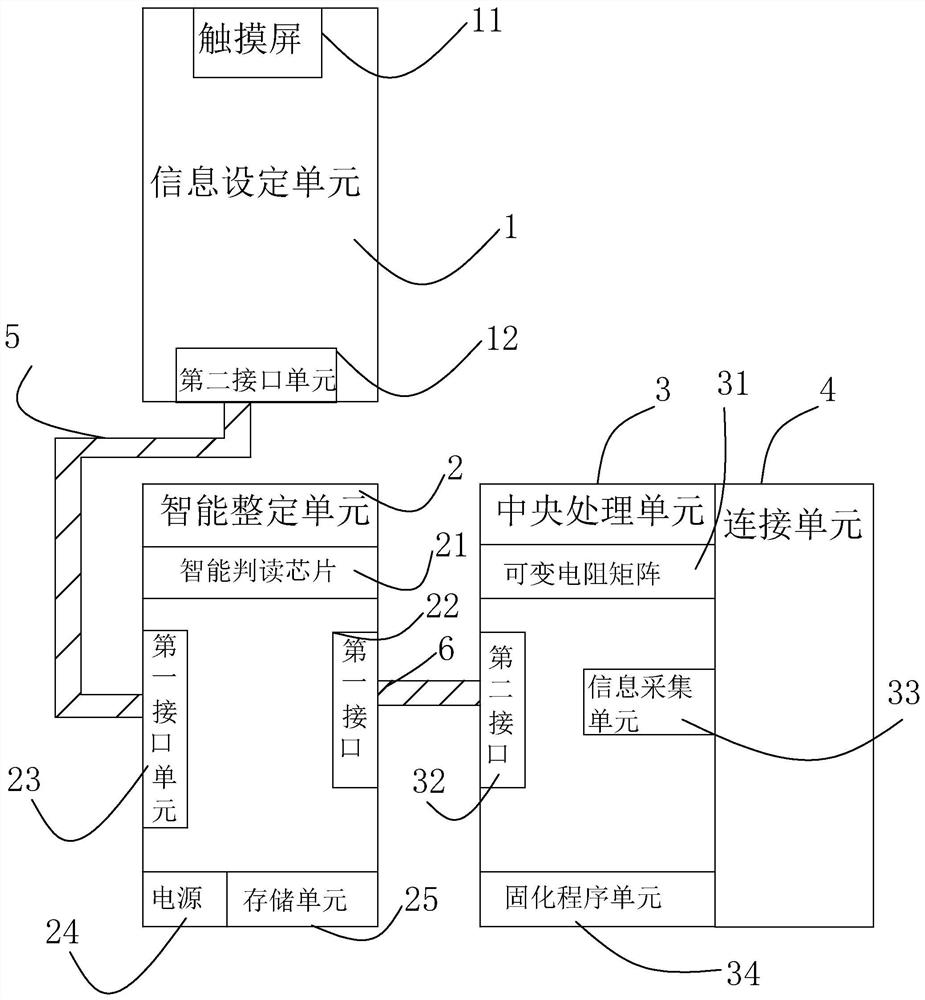

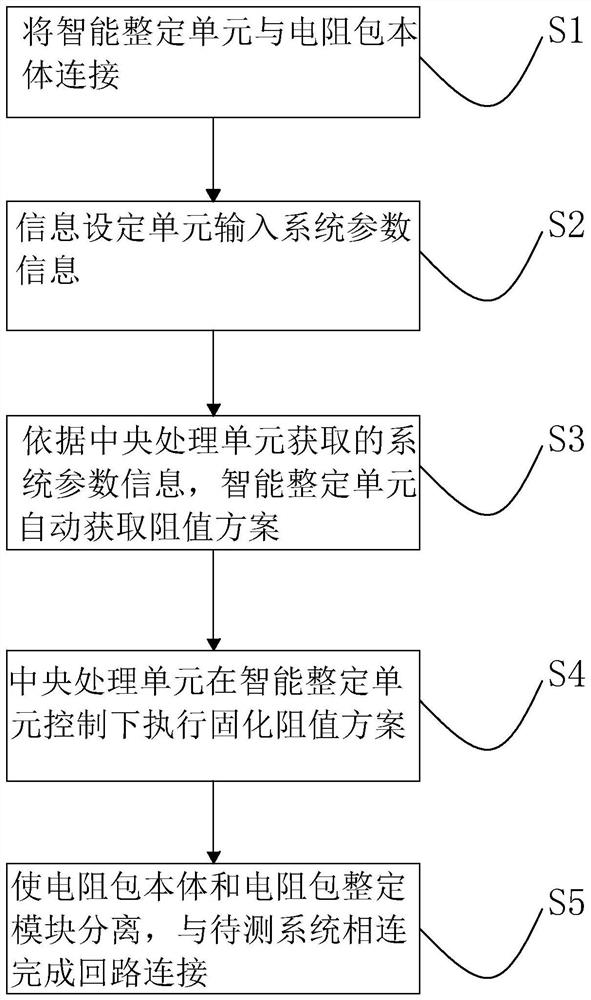

Intelligent-setting resistor packet special for loop detection and setting method of intelligent-setting resistor packet

PendingCN114415063ARealize automatic tuningUniversalShort-circuit testingContinuity testingControl engineeringProcessing element

The invention provides an intelligent setting resistor packet special for loop detection and a setting method thereof.The intelligent setting resistor packet special for loop detection comprises a resistor packet body and a resistor packet setting module, and the resistor packet body and the resistor packet setting module are connected with each other; the resistance pack body comprises a central processing unit which is used for adjusting different resistance value matching schemes and solidifying the resistance value schemes; the resistor packet setting module comprises an intelligent setting unit which is used for detecting a resistor scheme by a parameter intelligent interpretation loop and executing a curing program; and the information setting unit is used for determining connected system information and parameter information required by loop detection. Firstly, the information setting unit inputs parameters, the parameters are input to the intelligent setting unit, the intelligent setting unit dispatches the central processing unit to carry out the resistance curing process after information interpretation, adjustment and setting only need to be carried out through the intelligent setting unit, automatic resistance adjustment is carried out according to the requirements of different engineering sites, and the flexibility degree is high.

Owner:ZHEJIANG SUPCON TECH

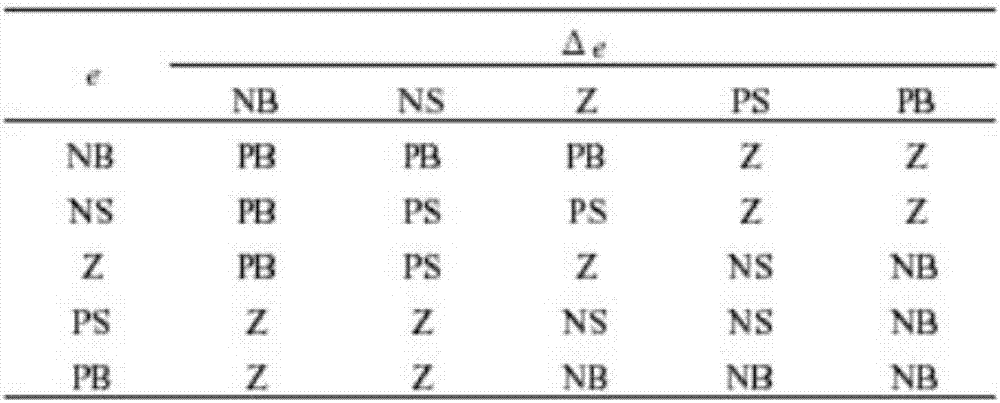

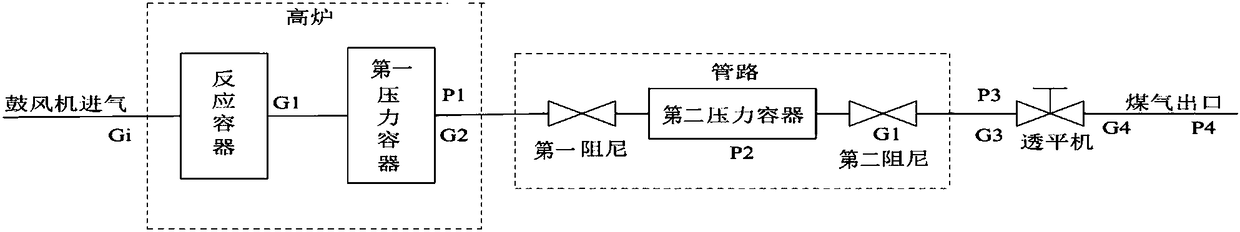

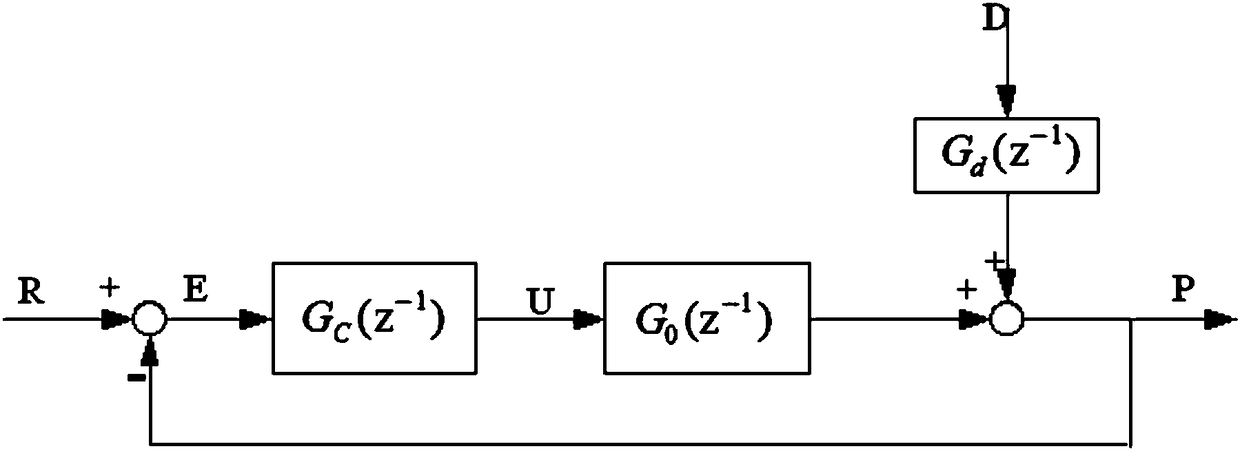

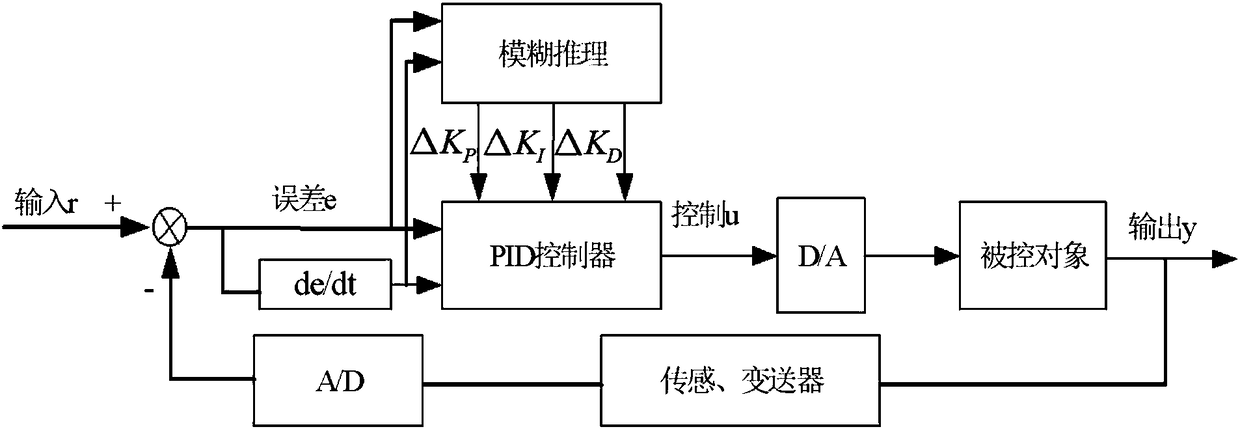

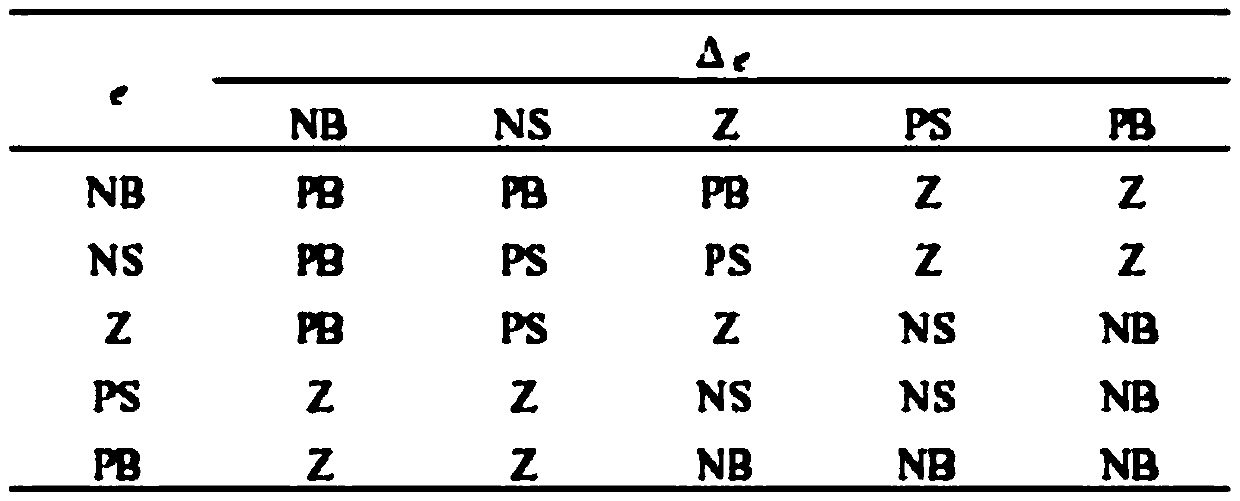

Blast furnace TRT top pressure control model based on fuzzy adaptive control and control method

PendingCN108301886AStructure determinationStable controlBlast furnace detailsSteam engine plantsFuzzy ruleDynamic models

The invention discloses a blast furnace TRT top pressure control model based on fuzzy adaptive control and a control method. The blast furnace TRT top pressure control model comprises a blast furnaceTRT. One end of the blast furnace TRT is connected with blast furnace gas generated after dust removal, one path of the other end of the blast furnace TRT is connected with a generator through a pipeline, and the other path of the other end of the blast furnace TRT is connected with a gas pipe network outlet. The error e and the error change ec are adopted as input, e and ec are constantly detected during operation, fuzzy inference is carried out through the fuzzy rule, and a fuzzy matrix table is searched for parameter adjustment to meet the requirements of e and ec for PID parameter self-adjusting at different moments; and PID parameters are modified online through the fuzzy rule, the blast furnace TRT system is subjected to reasonable simplification treatment, main disturbance of the blast furnace top pressure under the normal work condition is introduced into the model, a dynamic model of the blast furnace top pressure under the normal work condition is ensured, and therefore the foundation is laid for subsequent study and analysis of the blast furnace top pressure control algorithm.

Owner:YULIN UNIV

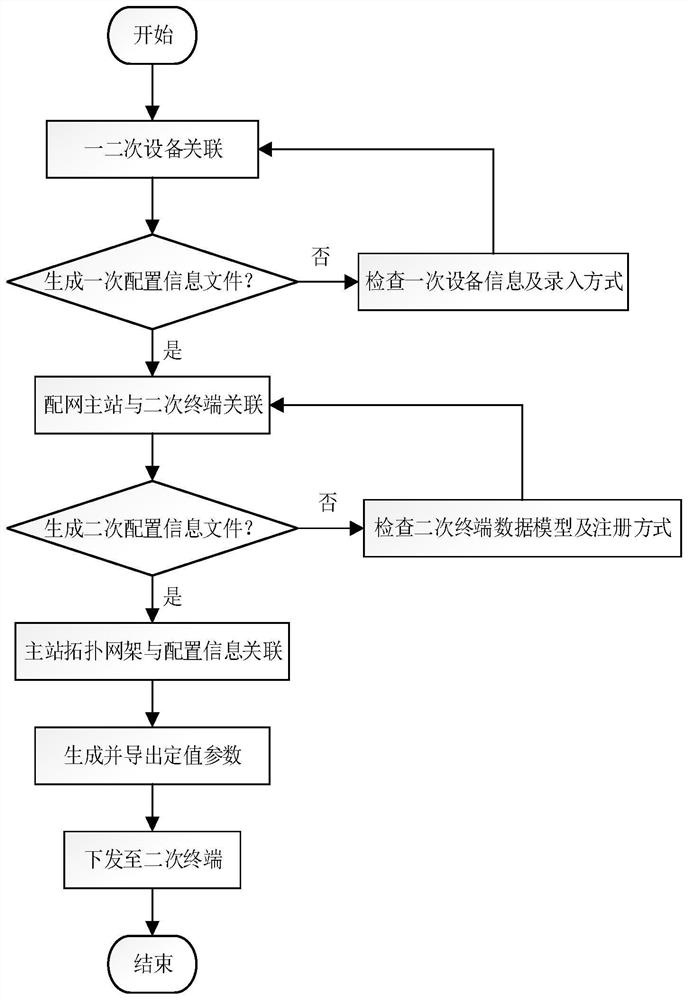

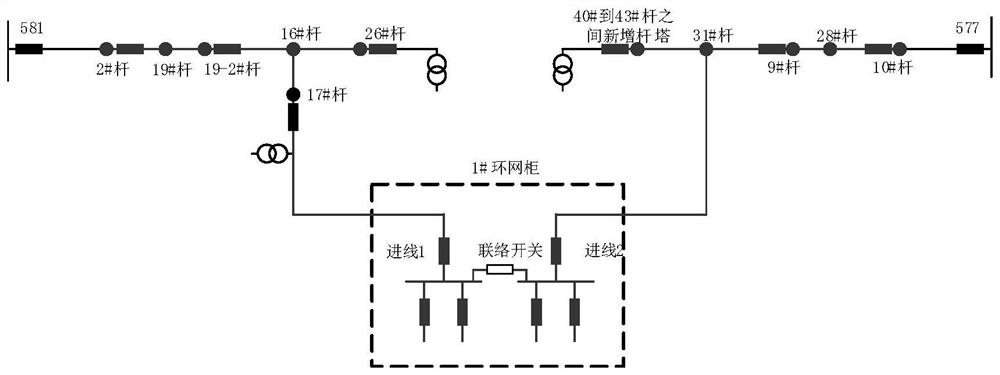

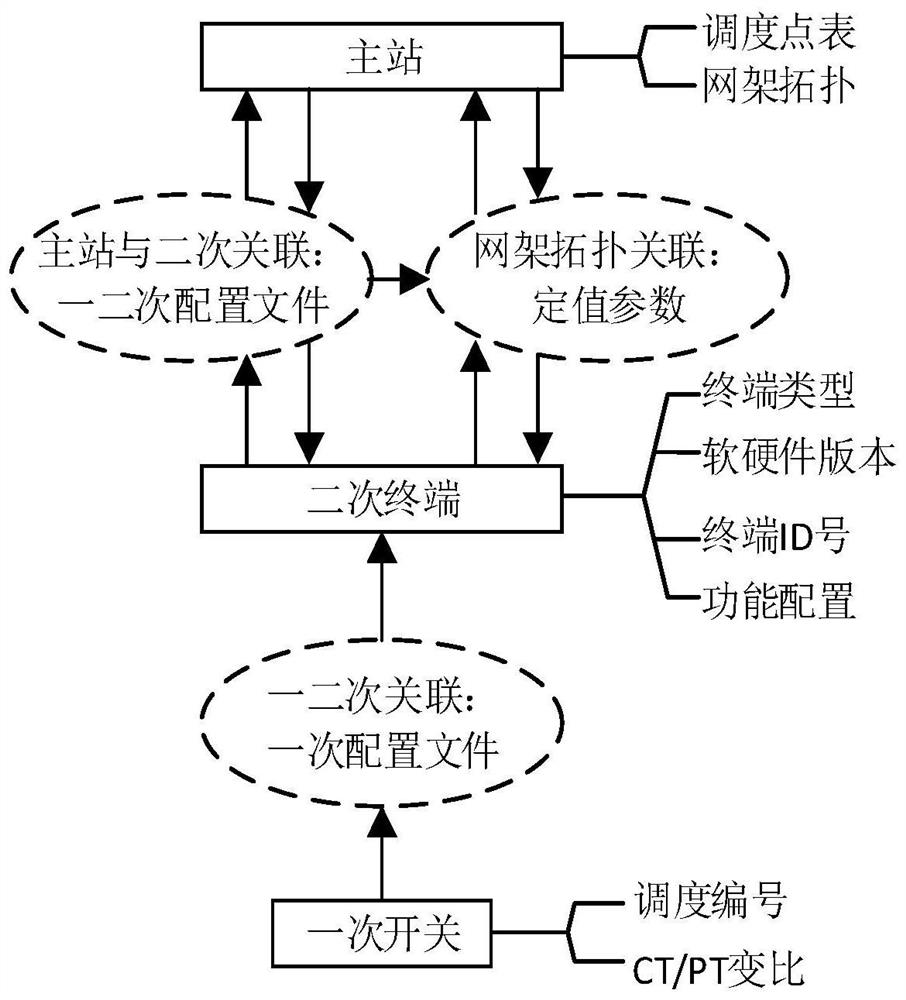

Distribution network constant value automatic setting method based on network frame topology and primary and secondary association

PendingCN113497434ARealize automatic tuningSafe and stable operationParameter calibration/settingEmergency protection data processing meansPrimary stationStation

The invention discloses a distribution network constant value automatic setting method based on grid topology and primary and secondary association, which comprises the following steps: step 1, performing primary and secondary equipment association, namely association between primary switch equipment and a secondary terminal, and generating a primary configuration information file after association; step 2, associating the distribution network master station with the secondary terminal, and generating a secondary configuration information file after association; and step 3, associating the network frame topology of the main station with the primary configuration information file and the secondary configuration information file, finally generating and exporting constant value parameters according to a related constant value setting principle and method, and uniformly issuing the constant value parameters to a secondary terminal by the main station. According to the setting method, automatic setting of the distribution network constant value parameters can be realized, the defects of low constant value calculation efficiency and low accuracy caused by human subjective factors are overcome, and the operation and maintenance cost and the error probability are reduced.

Owner:NR ELECTRIC CO LTD +1

A method and system for automatically adjusting linpack performance testing

ActiveCN107451022BRealize automatic tuningRealize automatic configurationDetecting faulty hardware by configuration testFaulty hardware testing methodsAutomationOperations order

Owner:ZHENGZHOU YUNHAI INFORMATION TECH CO LTD

Speed loop control parameter setting method and device

ActiveCN109713977ARealize automatic tuningImprove the efficiency of settingMotor parameters estimation/adaptationMotor speedComputer science

The invention discloses a speed loop control parameter setting method and device. The method comprises the following steps: determining a proportional parameter theoretical value (shown in the description) and an integral parameter theoretical value (shown in the description) of a speed ring PI controller according to a motor speed ring parameter theoretical calculation formula as a proportional parameter initial value (shown in the description) and an integral parameter initial value (shown in the description) for the setting of a speed ring; determining a minimum evaluation value of an errorintegral performance evaluation function in an iteration direction according to the proportional parameter initial value (shown in the description), the integral parameter initial value (shown in thedescription), and the set iteration step and formula, and obtaining a corresponding integral parameter and a corresponding proportion parameter when the minimum evaluation value is not larger than apreset threshold value. Through the method, the speed loop control parameter setting effect is improved, and the method does not depend on a model of a motor system, is wider in application range, iseasy for operation, and is high in setting efficiency.

Owner:XIAMEN HUALIAN ELECTRONICS CO LTD

A multi-model lf furnace electrode adjustment method based on steel grade clearance and slag thickness

ActiveCN105404149BEasy to controlRealize automatic tuningIncreasing energy efficiencyControllers with particular characteristicsReal-time Control SystemPower flow

The invention, which belongs to the field LF furnace electrode regulator field, relates to a multi-model LF furnace electrode adjusting method based on steel type clearance slag thickness. With the method, problems that the sensitivity of the controller is low and the network is not suitable for a real-time control system can be solved. Input data of an electrode regulator are collected, wherein the data include a three-phase secondary side current and three-phase secondary side voltage that are obtained by direct measurement, an initial current setting value of the electrode regulator, and data of the steel type, clearance, and slag thickness for setting a PID controller; according to the data, parameters of the PID controller are set in an on-line mode; static parameters of the set PID controller as well as the data of the steel type, clearance, and slag thickness are recorded, and an LF electrode PID setting model set is established; and after establishment of the PID setting model set, data of the steel type, clearance, and slag thickness are inputted, determination is carried out, and a proper model is invoked automatically. Therefore, optimization of an original control system is realized, thereby substantially improving the on-line adjusting process of the system and realizing better control of the electrode.

Owner:BENGANG STEEL PLATES +1

Industrial robot and its trajectory tracking control method based on iterative feedback adjustment

InactiveCN109669348BImprove control effectEliminate the effects of noise interferenceAdaptive controlControl engineeringIndustrial robotics

The invention discloses an industrial robot based on iterative feedback adjustment and a trajectory tracking control method thereof, and belongs to the field of industrial robot control. The method combines the limitation of the amplitude of a control input signal and trajectory tracking errors, establishes a trajectory tracking control criterion, derives to obtain a partial derivative of the control criterion relative to a speed controller and a position controller, then designs three iterative experiments and uses the collected data to complete the estimation of the information of the partial derivative of the control criterion, and realizes the update and correction of trajectory tracking controller parameters of joint drive systems. Compared with the prior art, the trajectory trackingcontrol method is a model-free adaptive control method which is not affected by unmodeled dynamics and modeling errors, the effect of noise disturbance by a method of repeatedly obtaining data by iteration is eliminated, and position following errors in an iteration domain are combined to adaptively update the trajectory tracking controller parameters of a correction system to ensure that the following control performance of the system is optimal.

Owner:HUAZHONG UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com