Intelligent PID control device

A control unit and control method technology, applied in the field of PID control, can solve the problems of slow system output response, difficult parameter adjustment, steady-state error, etc., and achieve the effects of high execution efficiency, convenient and fast use, and high control precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

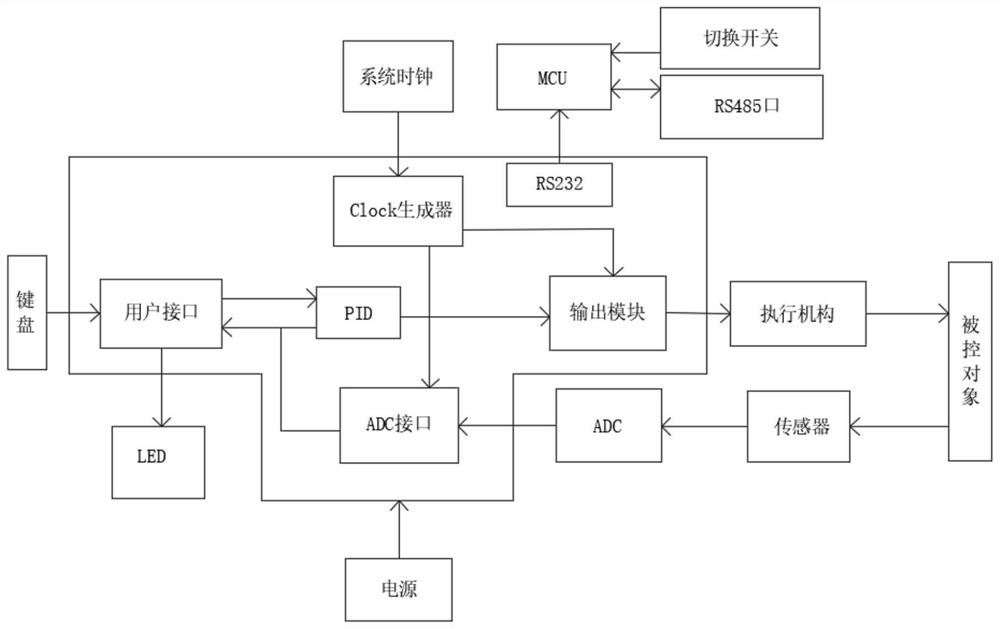

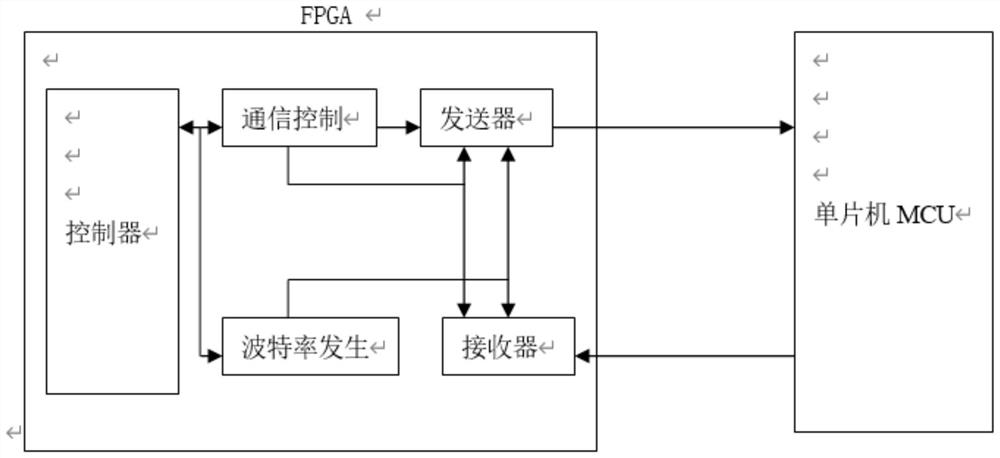

[0042] The technical solutions in the embodiments of the present invention will be clearly and completely described below with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only a part of the embodiments of the present invention, but not all of the embodiments.

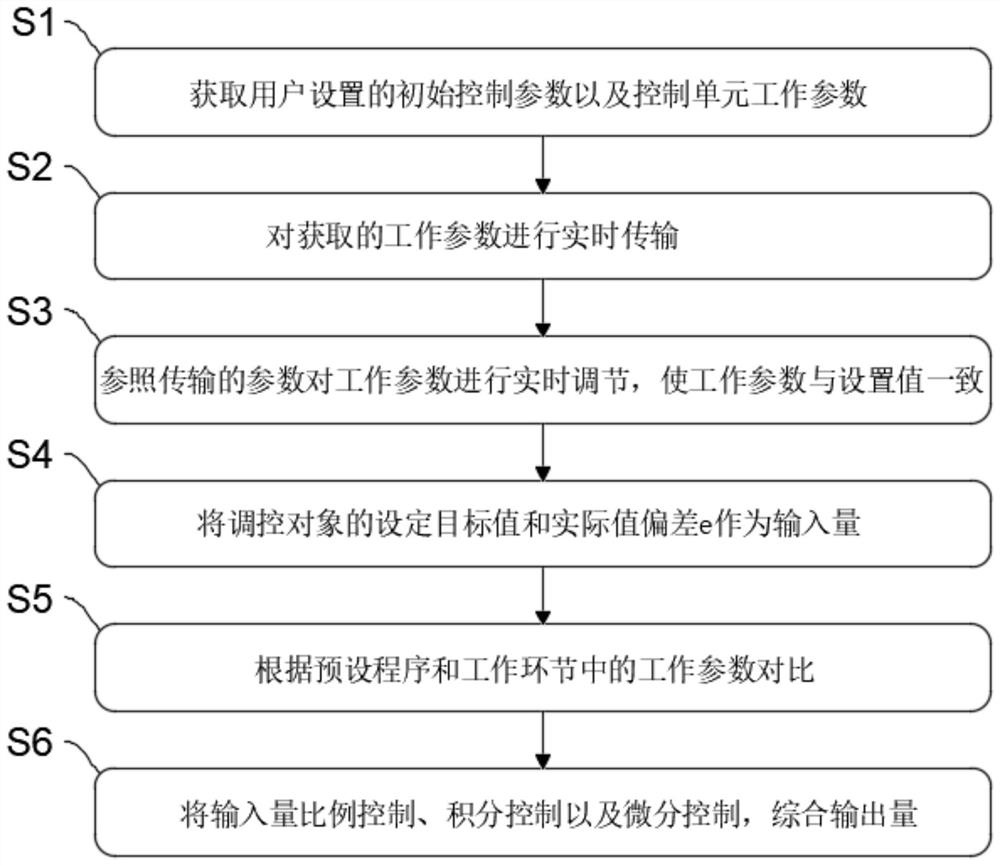

[0043] refer to Figure 1-4 , an intelligent PID control method, the steps are as follows:

[0044] S1: Obtain the initial control parameters set by the user and the working parameters of the control unit;

[0045] S2: Real-time transmission of the acquired working parameters;

[0046] S3: Adjust the working parameters in real time according to the working parameters transmitted in real time, so that the working parameters are consistent with the set values; the method is as follows:

[0047] First, set conservative parameters at the beginning of debugging to give a step given signal;

[0048] According to the output waveform of the cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com