Blast furnace TRT top pressure control model based on fuzzy adaptive control and control method

A fuzzy self-adaptive, control model technology, applied in steam engine installations, machines/engines, mechanical equipment, etc., can solve problems such as complexity, control algorithms cannot be improved and perfected, and lag in blast furnace top pressure regulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

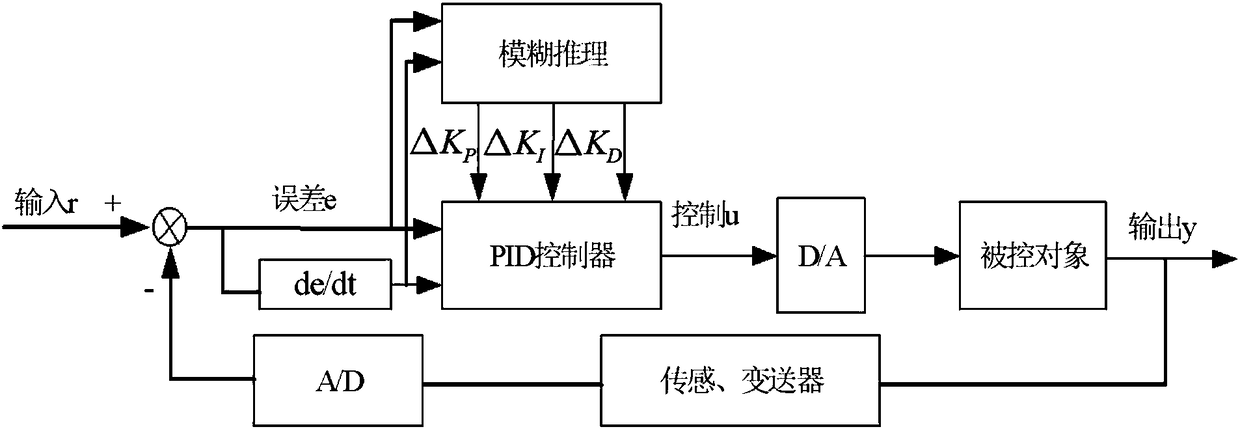

[0042] The invention provides a blast furnace TRT top pressure control system based on fuzzy self-adaptive PID control, combining the advantages of traditional PID control and modern fuzzy control, adopting fuzzy self-adaptive PID control, and applying fuzzy reasoning method to realize the control of blast furnace TRT top pressure The automatic tuning of PID parameters in the system is expected to improve the control effect and achieve stable control of the top pressure of the blast furnace.

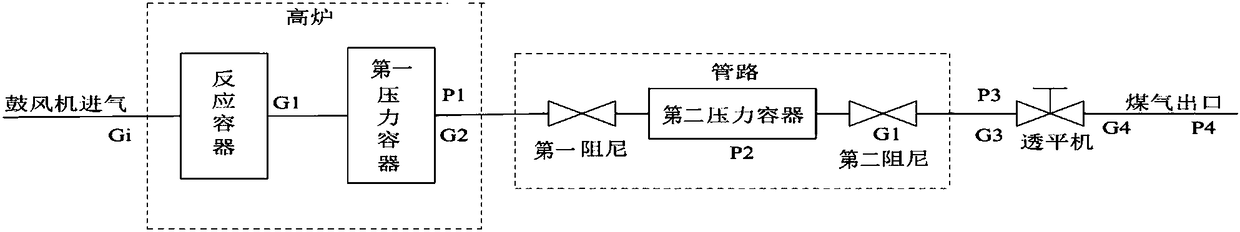

[0043] see figure 1 , a blast furnace TRT top pressure control system based on fuzzy self-adaptive PID control in the present invention, comprising a blast furnace, a pipeline and a turbine, and the blower air is discharged from the gas outlet after passing through the blast furnace, pipeline and turbine in sequence; A reaction vessel and a first pressure vessel are provided; the pipeline includes the first damper, the second pressure vessel and the second damper.

[0044] When the TRT de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com