Technology for sealing micropore opening

A microporous and open technology, applied in the field of semiconductor technology, can solve the problems of difficult control of film thickness uniformity, high operating cost, low deposition rate, etc., and achieve the effects of rich and diverse shapes, convenient processing, and high specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

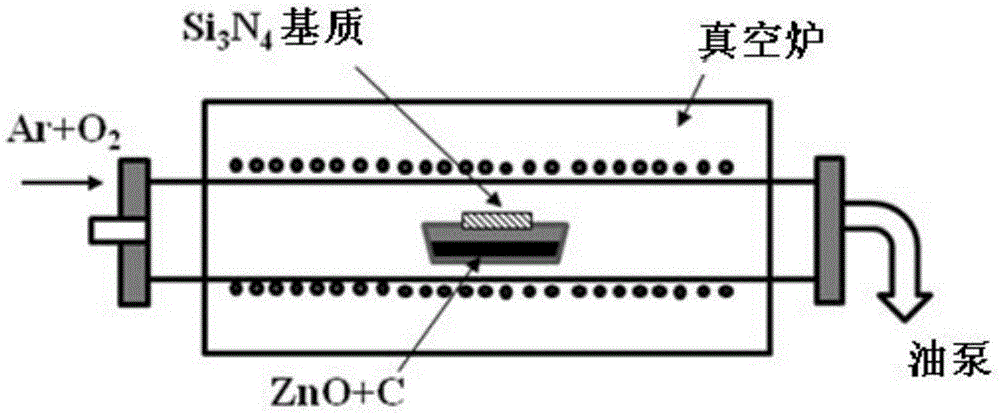

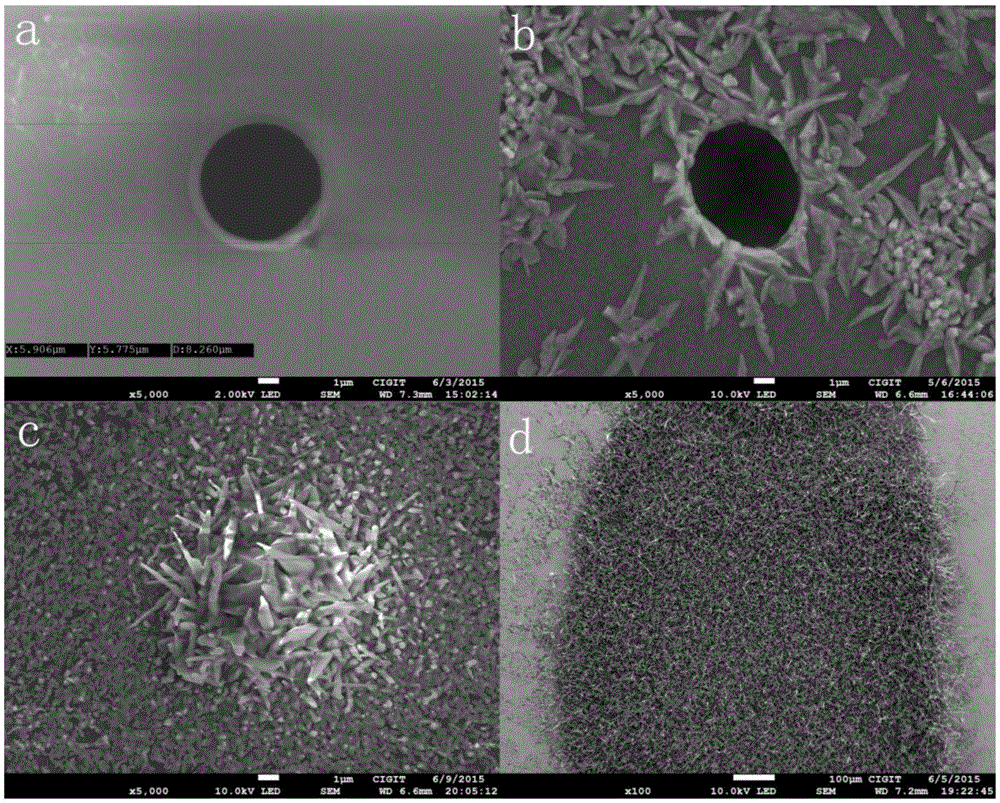

[0031] 1) Mix and grind ZnO powder and carbon powder at a mass ratio of 1:1, and place the powder in a corundum boat;

[0032] 2) In Si containing micropores with a diameter of 5 μm 3 N 4 The area around the holes of the substrate is sputtered with an appropriate amount of Au, the Si3N4 substrate containing micropores is placed on a corundum boat, and the micropores are exposed to the mixed powder;

[0033] 3) Place the corundum boat at the center of the tube furnace of the chemical vapor deposition equipment, evacuate the gas chamber, and increase the temperature of the tube furnace at a rate of 15 °C / min. When the temperature rises to 600 °C, the carrier gas Ar and O 2 Mix at a ratio of 100sccm: 1.5sccm while passing it into the gas chamber, keep the growth pressure at 30KPa, stop the temperature rise after the temperature rises to 960°C, and maintain this condition for 20 minutes of deposition.

Embodiment 2

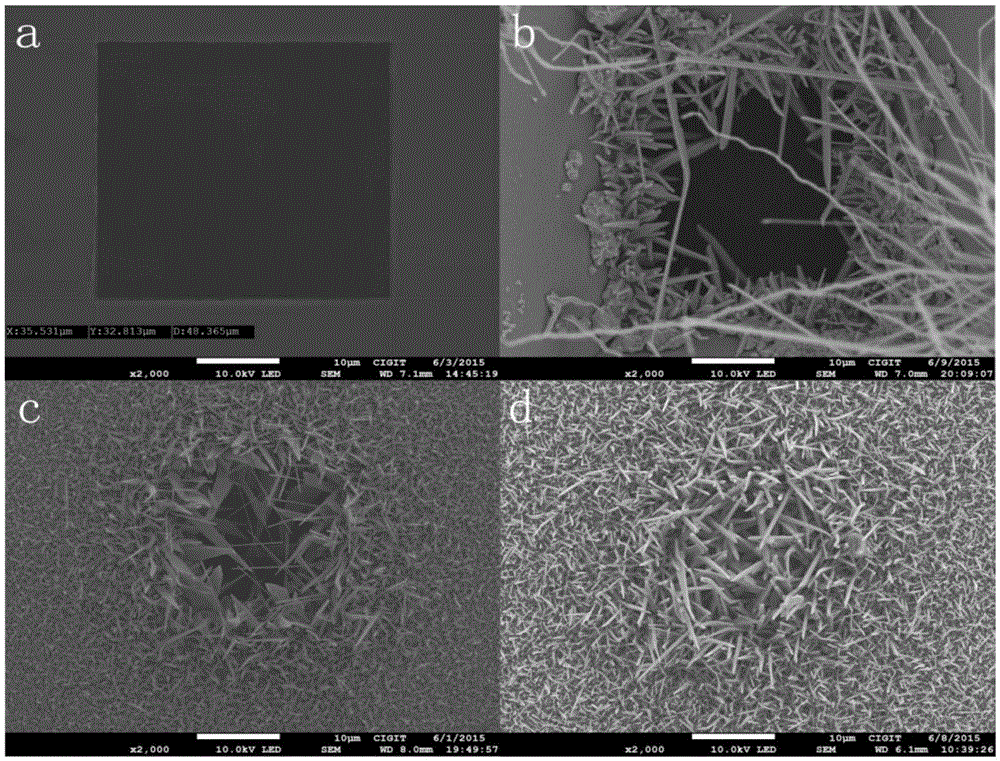

[0038] 1) Mix and grind ZnO powder and carbon powder at a mass ratio of 1:1, and place the powder in a corundum boat;

[0039] 2) In Si containing micropores with square pores with a side length of 35 μm 3 N 4 The area around the hole of the substrate is sputtered with an appropriate amount of Au, which will contain microporous Si 3 N 4The substrate is placed on the corundum boat with the opening of the pores facing the mixed powder;

[0040] 3) Place the corundum boat at the center of the tube furnace of the chemical vapor deposition equipment, evacuate the gas chamber, and increase the temperature of the tube furnace at a rate of 15 °C / min. When the temperature rises to 600 °C, the carrier gas Ar and O 2 Mix at a ratio of 100sccm: 1.5sccm while passing it into the air chamber, keep the growth pressure stable at 30KPa, stop the temperature rise after the temperature rises to 900°C and keep this condition for deposition for 20min, 30min, 40min.

[0041] image 3 Represent...

Embodiment 3

[0043] 1) Mix and grind ZnO powder and carbon powder at a mass ratio of 1:1, and place the powder in a corundum boat;

[0044] 2) In Si containing micropores with square pores with a side length of 450 μm 3 N 4 The area around the holes of the substrate is sputtered with an appropriate amount of Au, the Si3N4 substrate containing micropores is placed on a corundum boat, and the micropores are exposed to the mixed powder;

[0045] 3) Place the corundum boat at the center of the tube furnace of the chemical vapor deposition equipment, evacuate the gas chamber, and increase the temperature of the tube furnace at a rate of 15 °C / min. When the temperature rises to 600 °C, the carrier gas Ar and O 2 Mix at a ratio of 100sccm: 1.5sccm while feeding into the gas chamber, keep the growth pressure stable at 30KPa, stop the temperature rise after the temperature rises to 1000°C, and maintain this condition for deposition for 20min and 50min.

[0046] Figure 4 Represents the SEM image...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com