Capsizing moment testing machine for measuring rotating drive pair and special-type turntable bearing

A technology for slewing drive and slewing bearing, which is used in mechanical bearing testing, measuring devices, and machine gear/transmission testing. , display the intuitive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In conjunction with the accompanying drawings, the present invention is described in detail in the form of embodiments. However, the present invention is not limited to the following examples.

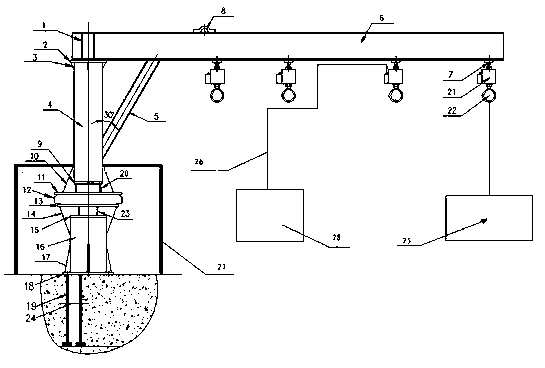

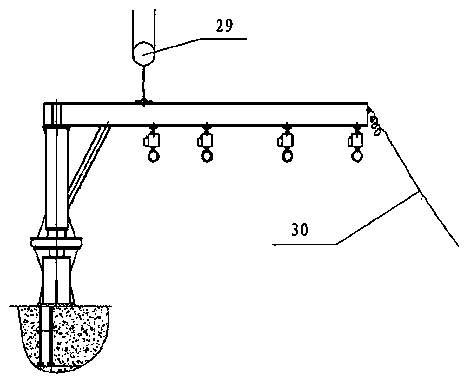

[0023] like figure 1 Shown: The overturning moment testing machine for measuring the slewing drive pair or the special turntable bearing described in this embodiment mainly includes a vertical beam 4, an inclined beam 5, a cross beam 6, a base 16, a force sensor 21, a weight frame 25 and a computer 28. One end of the crossbeam 6 is connected to the vertical beam 4 through the first flange 1. In order to ensure the strength, a stiffener plate 1 is fixedly connected to the joint between the first flange 1 and the crossbeam 6. The connection part of the vertical beam 4 is fixedly connected with the first triangular rib 3 . The lower end of the vertical beam 4 is connected to the upper end surface of the first round steel pipe 20 through the second flange 9 , and the third flange ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com