A control method and device for switching between series and parallel modes of a dual-motor power system

A mode switching and power system technology, applied in the field of hybrid power, can solve the problems of inertia impact of lock-up clutch, lower vehicle efficiency, clutch inertia impact, etc., and achieve the effect of reducing lock-up impact and improving drivability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

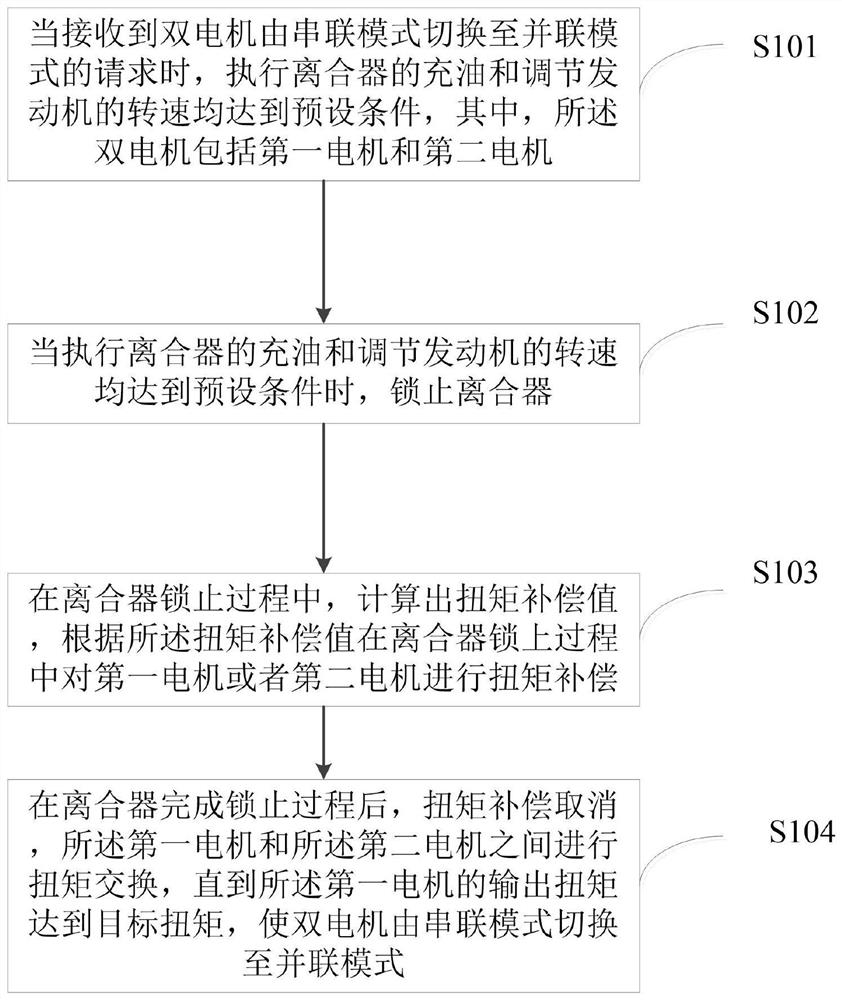

[0045] Embodiment 1 provides a control method for switching between series and parallel modes of a dual-motor power system, such as figure 1 shown, including the following steps:

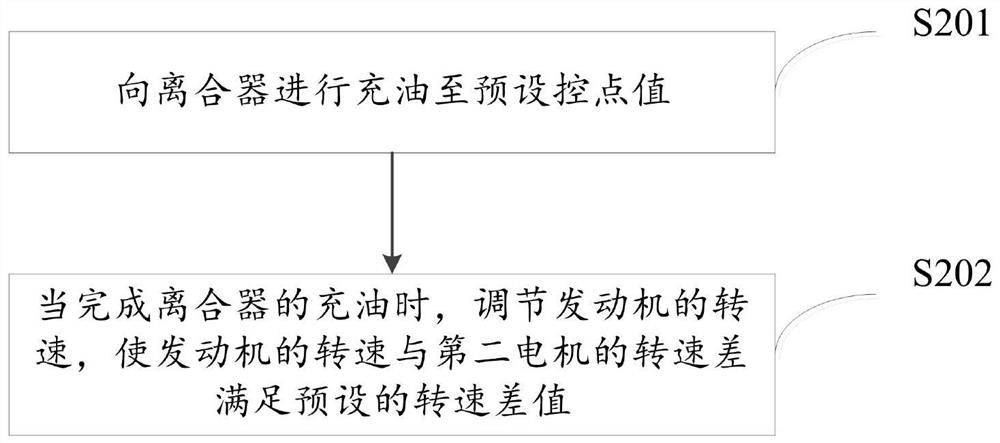

[0046]S101. When receiving a request to switch from the series mode to the parallel mode of the dual motors, perform the oil filling of the clutch and adjust the speed of the engine to meet preset conditions, wherein the dual motors include a first motor and a second motor;

[0047] S102. Locking the clutch when both the fuel filling of the clutch and the speed adjustment of the engine reach the preset conditions;

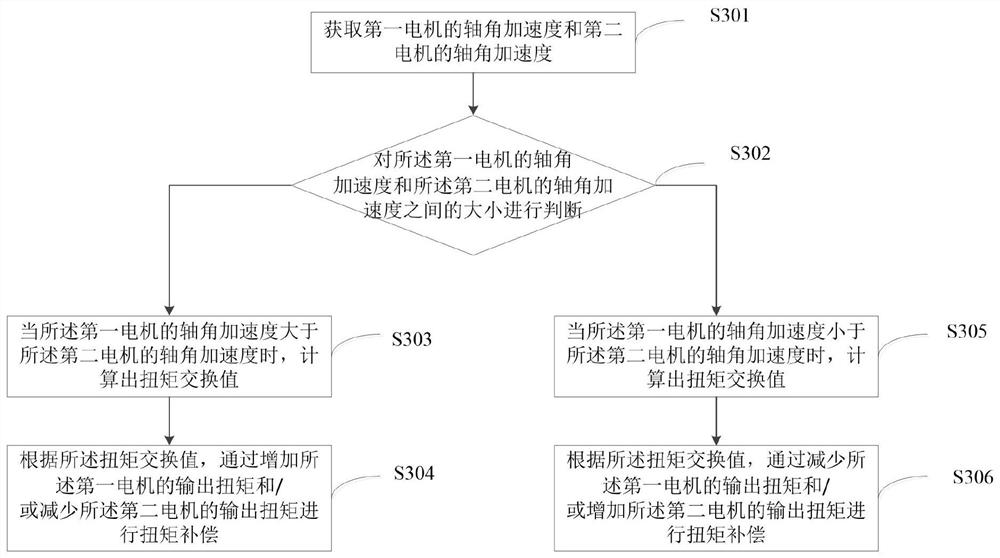

[0048] S103. During the clutch locking process, calculate a torque compensation value, and perform torque compensation on the first motor or the second motor during the clutch locking process according to the torque compensation value;

[0049] S104. After the clutch completes the locking process, the compensation is cancelled, and the torque is exchanged between the first motor and the...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap