Automatic paper filling equipment based on intelligent shoe packaging

A paper jamming and equipment technology, applied in the field of automatic paper jamming equipment, can solve the problems of low efficiency, low precision, and low paper jamming efficiency, and achieve the effects of improving efficiency, simplifying paper jamming process, and saving processing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

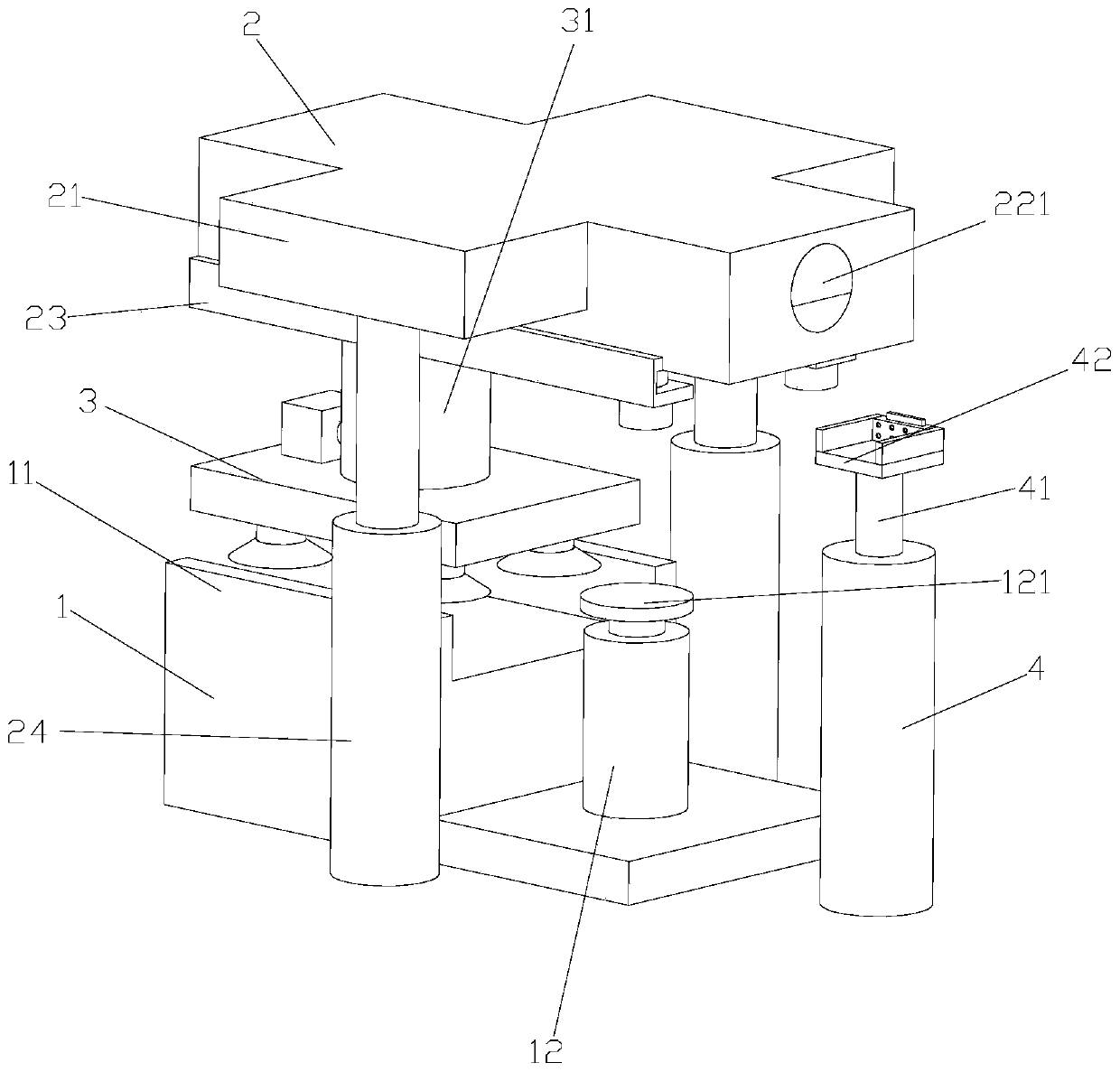

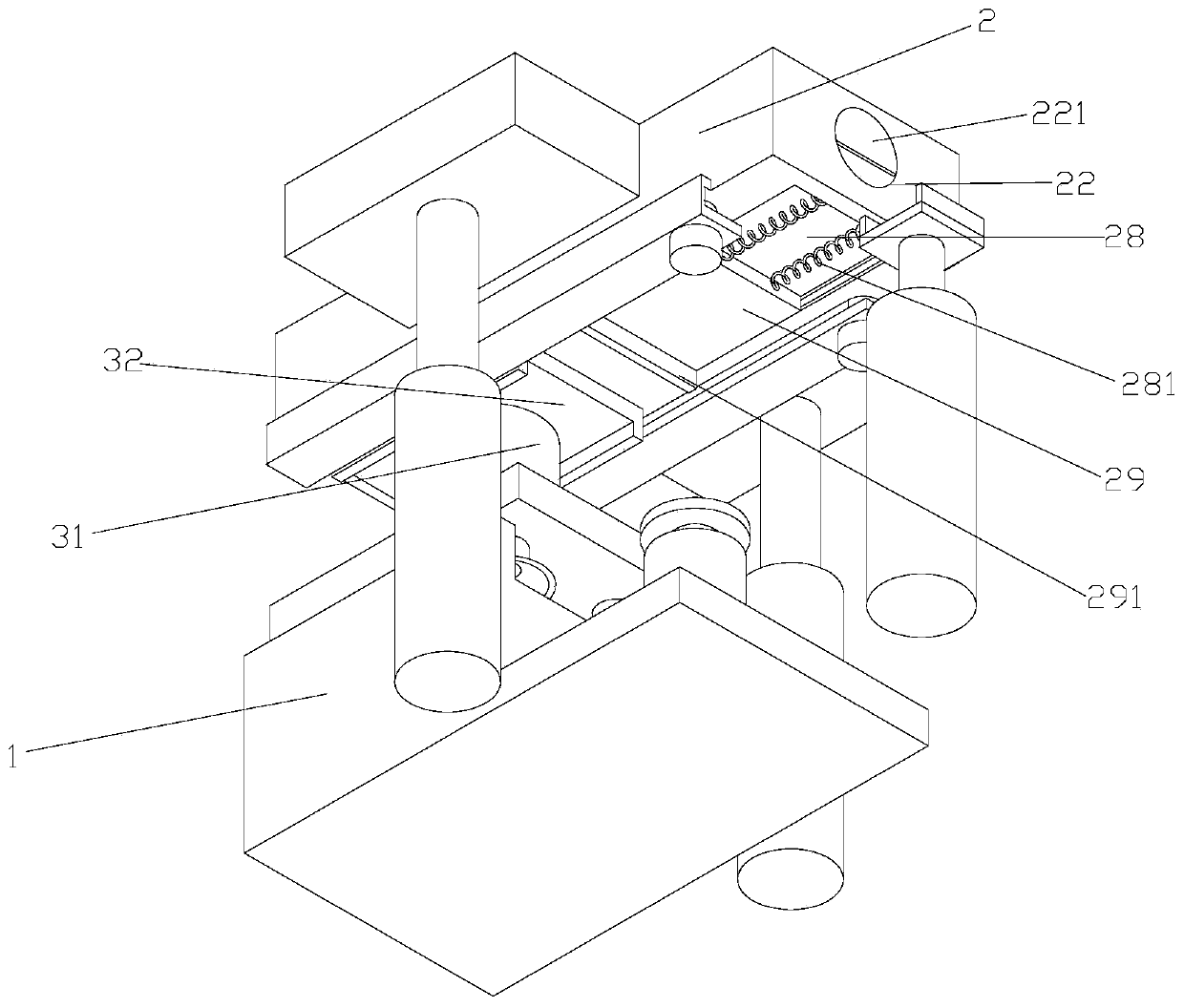

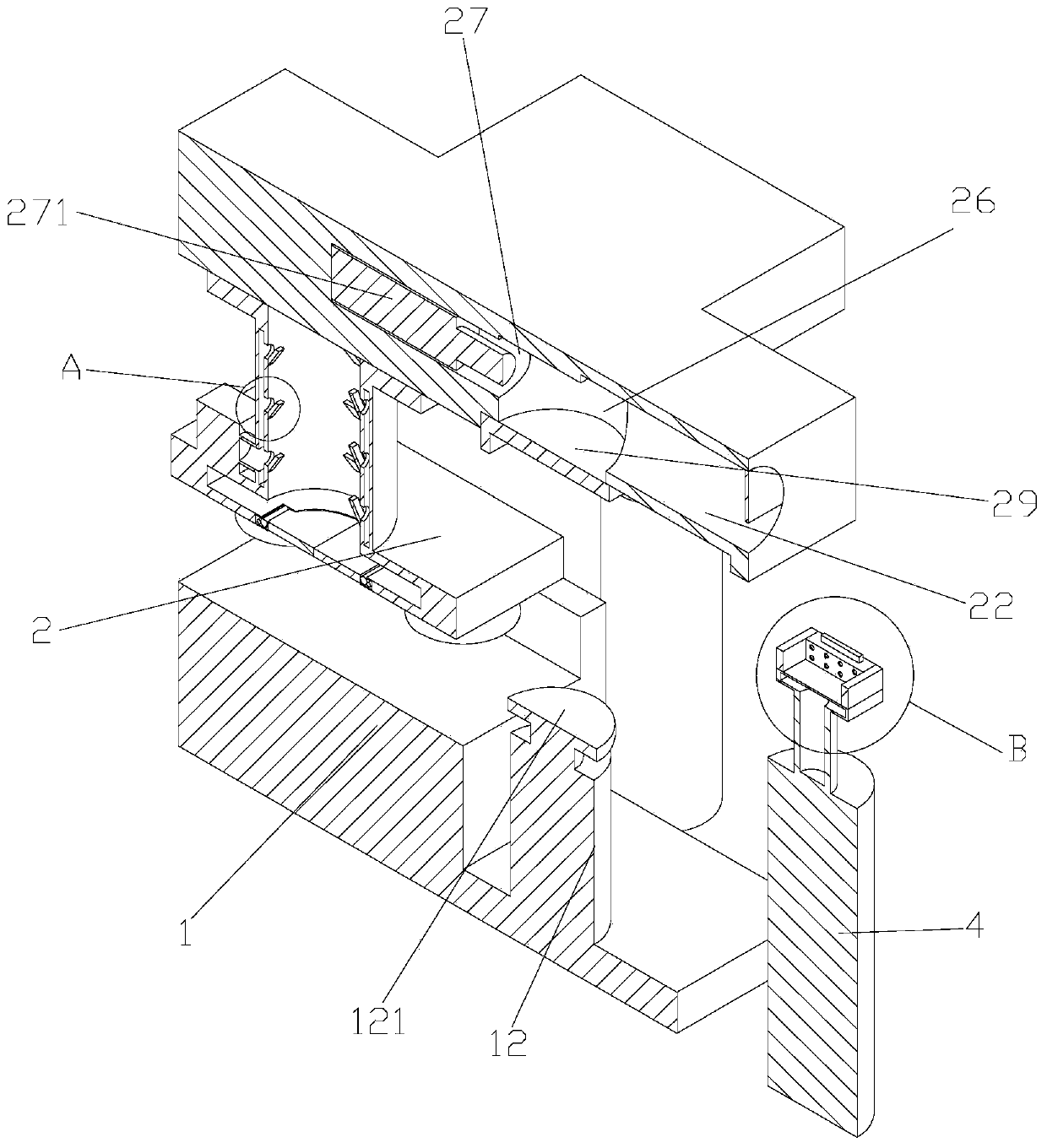

[0033] like Figure 1-16 As shown, an automatic paper stuffing device based on intelligent packaging of footwear, including a base 1, a mounting plate 2 above the base 1, a pick-up device at the bottom of the mounting plate 2 and a The paper jamming device on one side of the base 1, first baffles 11 are respectively provided on both sides of the base 1; a third connecting block 21 is provided on the side wall of the mounting plate 2, and the third connecting block The bottom of 21 is provided with a hydraulic cylinder 24; under the action of the hydraulic cylinder, the mounting plate can be driven to perform lifting motion, thereby driving the reclaiming device to perform lifting motion; the reclaiming device includes a movable plate 32 located at the bottom of the mounting plate 2, The first connecting pipe 31 located at the bottom of the movable plate 32 and the connecting plate 3 located at the bottom of the first connecting pipe 31, the movable plate is provided with a thi...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap