Injection mold head

A technology for injection molds and mold heads, which is applied in the field of molds and can solve problems such as deviation of plastic cooling time and quality impact of plastic products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

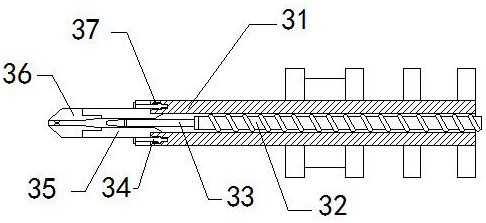

[0026] For example figure 1 -example Figure 5 Shown:

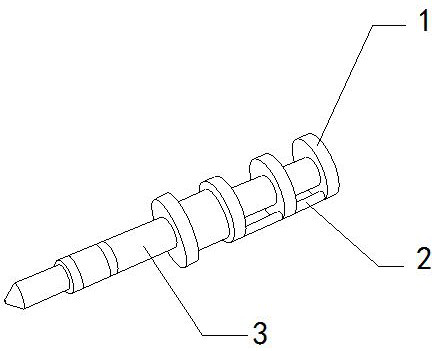

[0027] The present invention provides a die head of an injection mold, the structure of which includes a connecting end 1, a stabilizing rod 2, and an extrusion head 3. The stabilizing rod 2 is embedded and connected to the connecting end 1. Integrated structure; the extrusion head 3 includes a pipe body 31, a screw push rod 32, a booster rod 33, a connecting column 34, a joint block 35, an extrusion mechanism 36, and an elastic strip 37. The screw push rod 32 is connected to the tube The body 31 is threaded, the booster rod 33 is welded to the front end of the screw push rod 32, one end of the connecting column 34 is embedded and connected with the joint block 35, and the other end of the connecting column 34 is in clearance fit with the pipe body 31, The combination block 35 and the pipe body 31 are of an integrated structure, the extruding mechanism 36 is installed at the front end of the combination block 35 , and t...

Embodiment 2

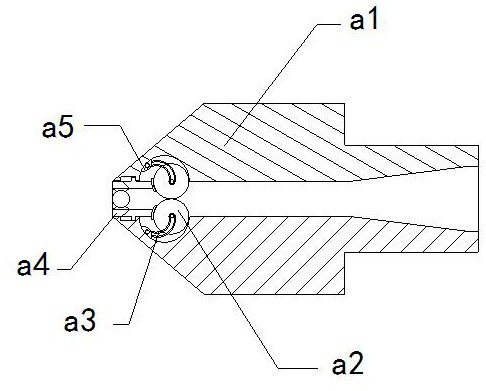

[0034] For example Figure 6 -example Figure 8 Shown:

[0035] Wherein, the clearing mechanism b5 includes an ejector block b51, a telescopic plate b52, an outer ring b53, a pull bar b54, a linkage rod b55, a guide frame b56, and an inner ring b57, and the ejector block b51 and the telescopic plate b52 are integrated structure, the telescopic plate b52 is movably engaged with the guide frame b56, the outer ring b53 is fixed at the outer position of a57, the pull bar b54 is installed at the inner position of the outer ring b53, and one end of the linkage rod b55 is connected to the telescopic The plate b52 is embedded and connected, and the other end of the linkage rod b55 is in clearance fit with the outer ring b53. The guide frame b56 is embedded in the inner position of the inner ring b57. Evenly distributed in a circular shape on the guide frame b56, when the external plastic solution is squeezed in, the mechanism will be squeezed, and the mechanism can be bent, so that ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap