Power electrical transformer with self-cooling function

A technology of electric power and transformers, which is applied in the field of transformers, can solve the problems of closed protection in the normal temperature state when the voltage cannot be transformed, and achieve the effect of avoiding the use of electricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

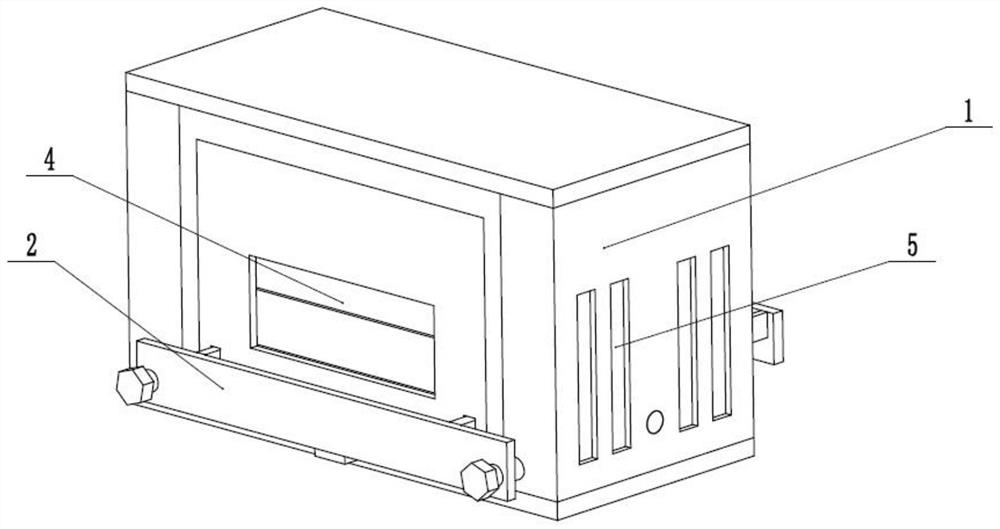

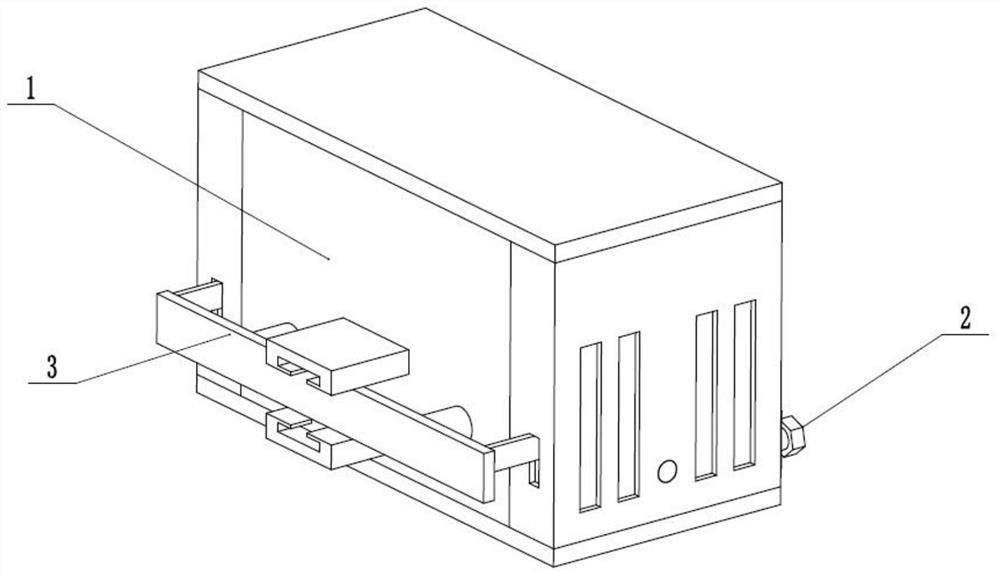

[0031] Such as Figure 1 to Figure 11As shown, a power electrical transformer with a self-cooling function includes a transformer outdoor closed protection frame 1, an adjustable transformer load fixing seat 2, a self-adjusting driver 3, a self-adjusting sliding front door 4, multiple ventilation side doors 5 and compressed air Expander 6, the adjustable transformer load fixing seat 2 is connected to the rear end of the transformer outdoor closed protection frame 1 through thread fit, and the front end of the adjustable transformer load fixing seat 2 is attached to the self-adjusting driver 3, The self-adjusting driver 3 and the self-adjusting sliding front door 4 are meshed and driven, and the self-adjusting sliding front door 4 is rotatably connected in the outdoor closed protection frame 1 of the transformer. Respectively hinged on the two ends of the inner wall of the closed protection frame 1 outside the transformer, the compressed air expander 6 is fixedly connected to t...

specific Embodiment approach 2

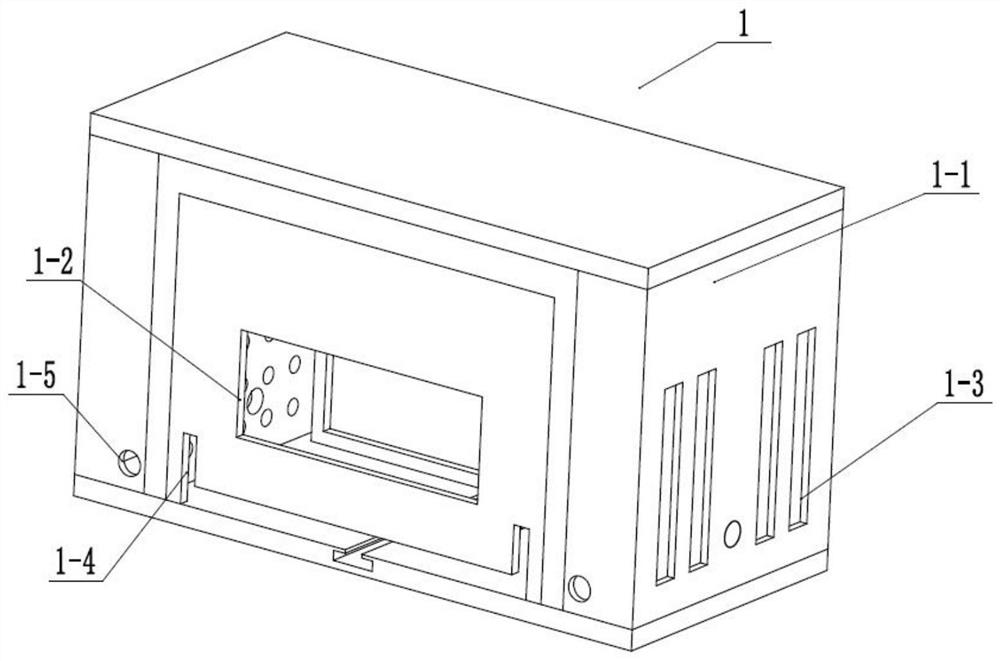

[0033] Such as Figure 1 to Figure 11 As shown, this embodiment will further explain Embodiment 1. The outdoor closed protective frame 1 of the transformer includes a protective box 1-1, a front ventilation slot 1-2, a plurality of side ventilation slots 1-3, and an adjustment slot 1 -4. Two rotating round holes 1-5, two inner wall interval ventilation plates 1-6, T-shaped chute 1-7 under the inner wall, two front sliding seats 1-8 and two limiting rack chute 1 -9, the center of the rear end of the protection box 1-1 is provided with a connected front ventilation slot 1-2, and the two ends of the protection box 1-1 are respectively provided with a plurality of connected side ventilation slots 1-3, the protection box The lower side of the rear end of 1-1 is provided with a connected adjustment slot 1-4, two rotating round holes 1-5 are evenly arranged on the rear end of the protection box 1-1, and the ventilation plates 1-6 are evenly spaced between the two inner walls. Fixedl...

specific Embodiment approach 3

[0035] Such as Figure 1 to Figure 11 As shown, this embodiment will further explain Embodiment 2. The adjustable transformer load fixing seat 2 includes a transformer 2-1, a transformer load slide base 2-2, an adjustment connecting plate 2-3 and two adjustment Bolt 2-4, the lower end of the transformer 2-1 is fixedly connected to the transformer load slide 2-2 by bolts, the transformer load slide 2-2 is slidably connected in the adjustment slot 1-4, and the adjustment connection plate 2- 3. It is fixedly connected to the rear end of the transformer bearing slide seat 2-2. The two adjusting bolts 2-4 are respectively connected to the adjusting connecting plate 2-3 through thread fit, and the two adjusting bolts 2-4 are respectively connected to the two Rotate in the circular hole 1-5. The transformer 2-1 is fixedly connected to the transformer bearing slide 2-2 by bolts; when the temperature of the transformer 2-1 rises, the temperature of the compressed air in the compressed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com