A kind of solder paste storage management mechanism and its working method

A management mechanism and solder paste storage technology, which is applied in the direction of storage devices, packaging, and types of packaged items, can solve the problems of inconvenient handling and easy jamming of solder paste, and achieve the effects of easy use, convenient operation, and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

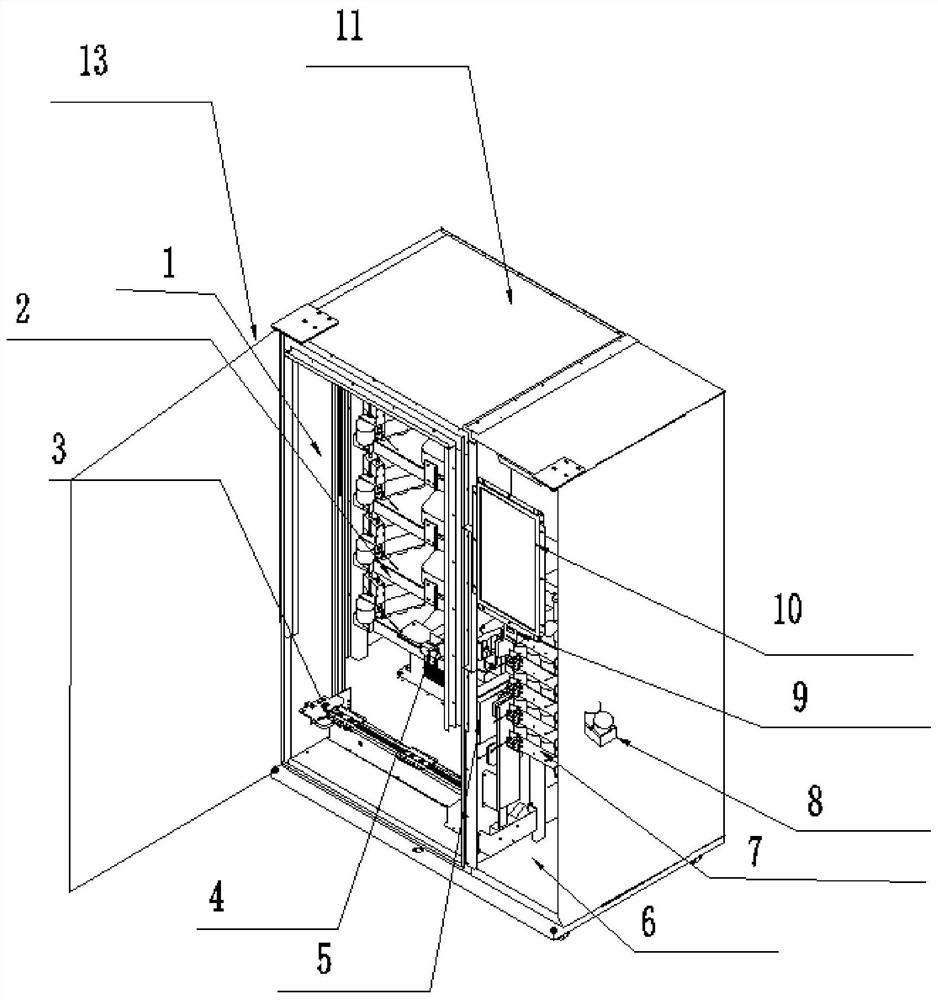

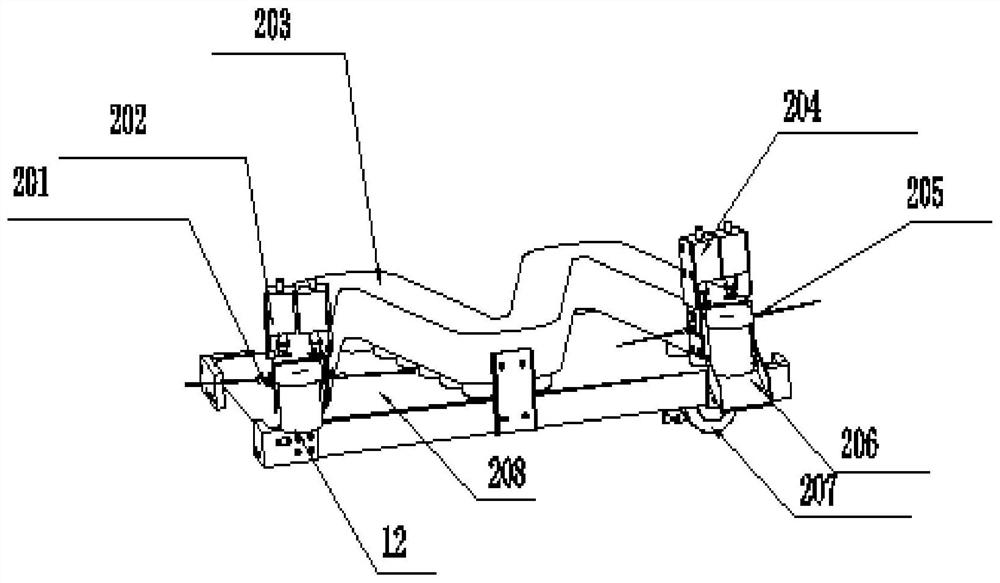

[0027] A solder paste storage management mechanism includes a refrigerating chamber 1, a refrigerating storage track 2, a return chamber 6 and a box body 11. The front of the box body 11 is provided with a code scanning and printing integrated machine 9 and a touch screen 10. After that, the user opens the transparent tempered glass door 13, and the transparent tempered glass door 13 is used to observe the state of the solder paste. Then the user scans the barcode on the solder paste with the barcode scanning and printing all-in-one machine 9. If there is no barcode, print the barcode and paste it on the On the product, the feeding blocking electromagnet 202 corresponding to the refrigerated storage track 2 is then lifted, the solder paste body 12 is put into the conveyor belt 208 in the refrigerated zone, and the corresponding refrigerated zone conveyor motor 207 on the refrigerated storage track 2 starts to work, and the feeding port The feed sensor 201 in the refrigerated ar...

Embodiment 2

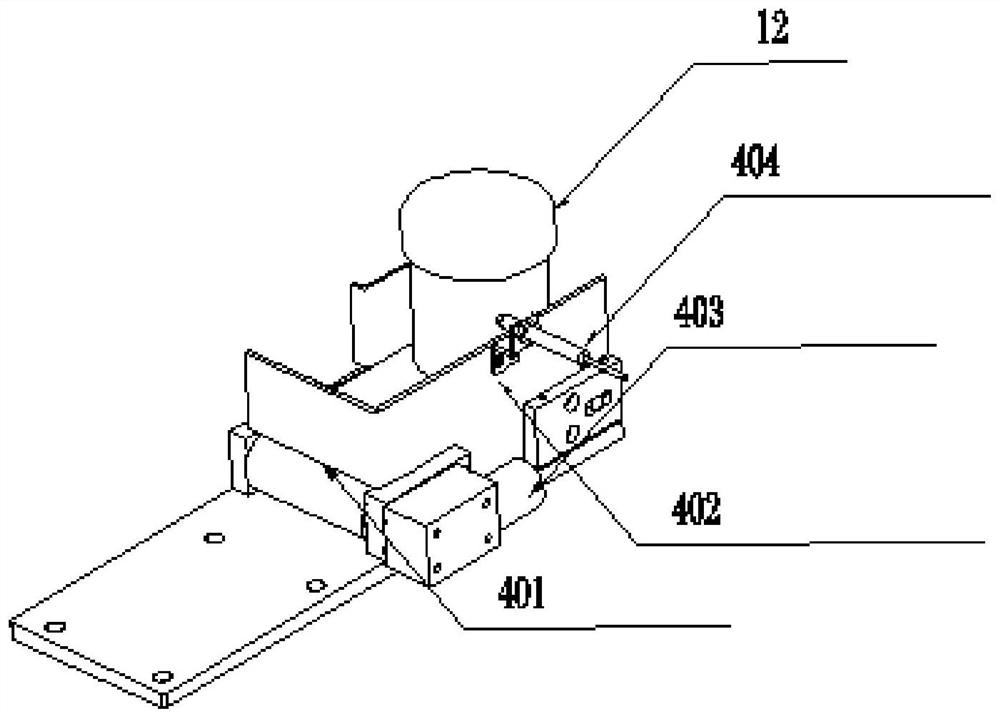

[0031] A solder paste storage management mechanism includes a refrigerating chamber 1, a refrigerating storage track 2, a return chamber 6 and a box body 11. The front of the box body 11 is provided with a code scanning and printing integrated machine 9 and a touch screen 10, and users can reserve tin through the touch screen 10. After the paste body 12 takes the material and reaches the solder paste temperature return time, the XZ axis moving shaft assembly 3 moves the connecting assembly 4 to the corresponding outlet of the refrigerated storage track 2, the conveyor belt 208 in the refrigerated area starts to work, and the refrigerated area discharges the material. The blocking electromagnet 204 is lifted up, and after the solder paste body 12 is in place, the refrigerating area discharge sensor 205 senses the product and then sends a signal, the refrigerating area conveyor 208 stops working, and the refrigerating area discharge blocking electromagnet 204 is put down, blocking...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com