Liquid atomization device

A liquid atomization and liquid technology, applied in the field of atomizers, can solve the problem of inconvenient movement of liquid atomization devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The application will be described in further detail below in conjunction with the accompanying drawings.

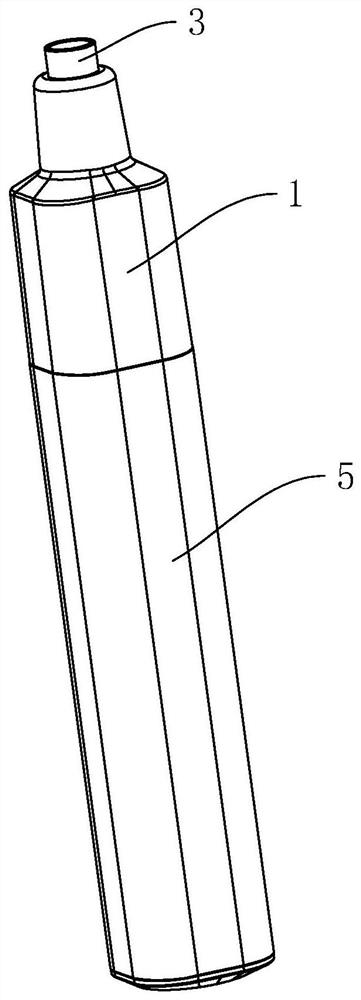

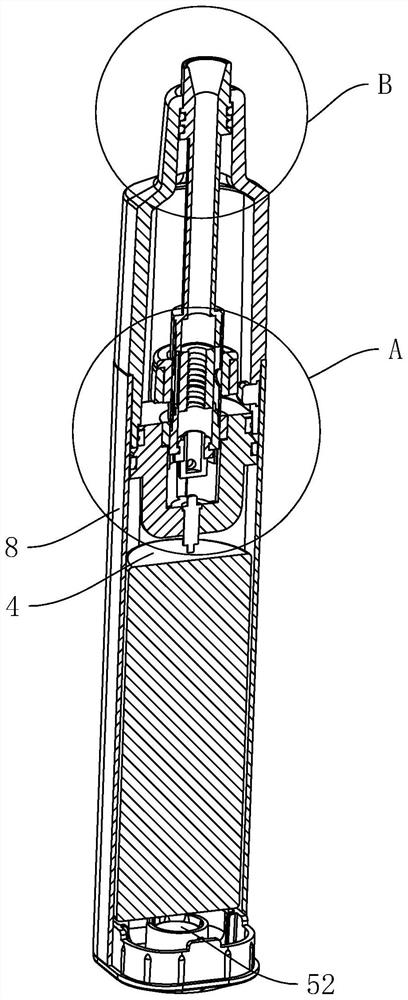

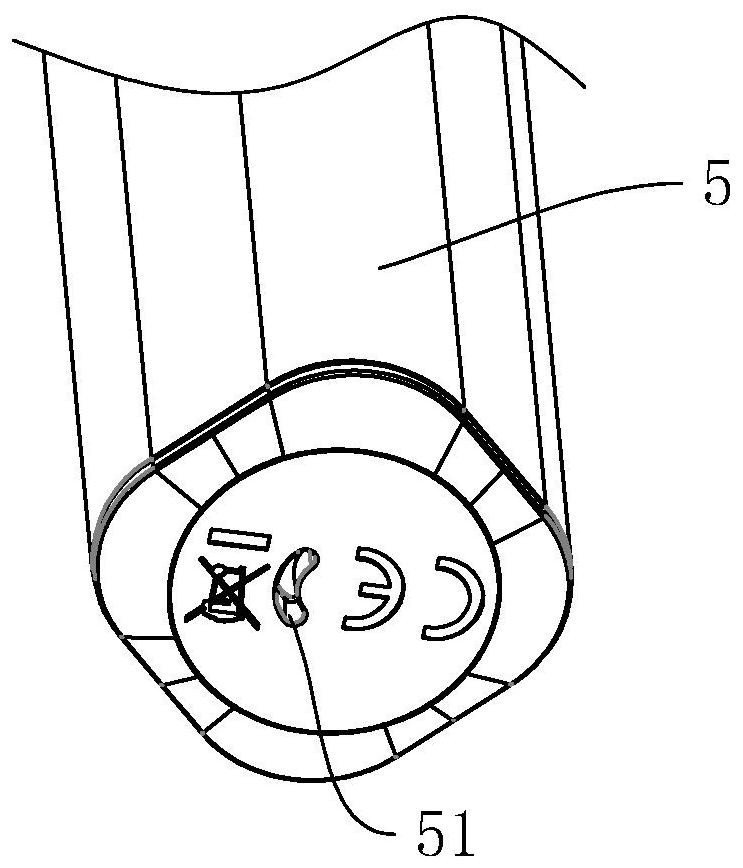

[0032] A liquid atomization device disclosed in the present application, such as figure 1 with figure 2 As shown, it includes a liquid chamber 1 with openings at both ends, an atomizing core 2 installed in the liquid chamber 1, an air guide tube 3 coaxially connected to the atomizing core 2, and a power supply for the atomizing core 2 connected to the liquid chamber 1 The cell 4. The opening at one end of the liquid chamber 1 is sleeved with a housing 5 with an opening at one end. The battery cell 4 is arranged in the housing 5, and the end surface of the housing 5 away from the liquid chamber 1 is provided with an air inlet 51 communicating with its inner cavity (see image 3 ), a flow sensor 52 is clamped in the inner cavity of the housing 5 close to the air inlet 51, and the flow sensor 52 is electrically connected to the battery cell 4 to control the on-off ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap