A kind of production method of low-temperature annealing ultra-deep drawing cold-rolled steel plate and cold-rolled steel plate

A production method and low-temperature annealing technology, applied in the field of steel rolling, can solve problems such as increasing the production cost of steel plates, and achieve the effects of low energy consumption, high elongation, and low yield strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the objectives, technical solutions and advantages of the present invention clearer, the present invention will be further described in detail below with reference to the embodiments. It should be understood that the specific embodiments described herein are only used to explain the present invention, but not to limit the present invention.

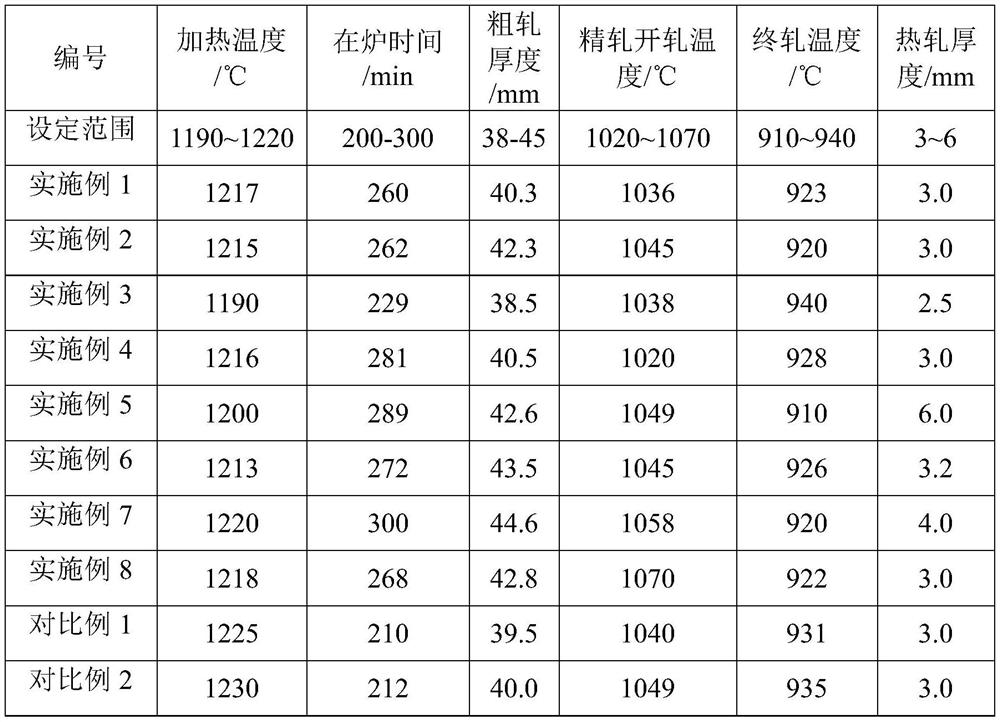

[0022] The production method of the low-temperature annealed ultra-deep-drawing cold-rolled steel sheet according to the present invention generally includes casting a slab, heating the slab to a temperature above the recrystallization temperature for hot rolling, cooling the hot-rolled slab and coiling it into a coil, and then uncoiling and cleaning. , cold rolling to obtain strip steel, and finally continuous annealing and smoothing of strip steel to obtain finished steel plate. Specifically, by controlling the temperature of each step in the hot rolling and annealing treatment and other related parameters, the m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com