A kind of optical fiber mode field adapter assembly and preparation method thereof

A mode field adapter and optical fiber technology, applied in the field of all-fiber, can solve the problems of increasing the splice loss, difficult to achieve the mode field matching of the hollow core fiber, easy to damage the special cladding structure of the hollow core fiber, etc., so as to increase the cladding structure. Size, simple and efficient mode field matching, the effect of optimizing the fiber mode field profile

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

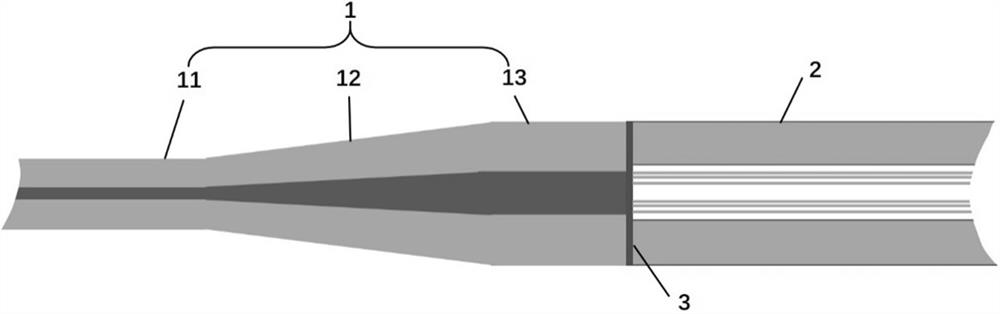

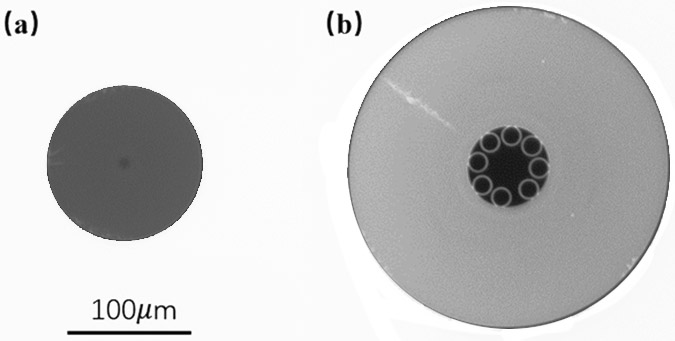

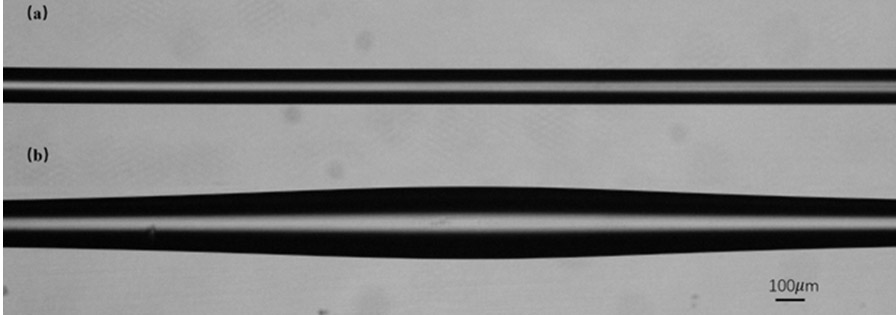

[0032] The selected solid core single-mode fiber 1 such as figure 2 As shown in (a), the core diameter is 8.2 μm, and the mode field diameter is 10.4 μm. The selected hollow core antiresonant fiber 3 such as figure 2 As shown in (b), the parameters are: the fiber core diameter is 35 μm, and the calculated mode field diameter is 25.2 μm. Since the cladding diameter of the single-mode fiber is much smaller than that of the hollow-core anti-resonant fiber, the splicing strength is low, and the mode field diameters of the two fibers are very different, resulting in a huge coupling loss. Considering the loss caused by mode-field mismatch, the coupling loss of the two fibers is estimated to be greater than 3dB.

[0033] In order to solve the problems of excessive splicing loss and low splicing strength of hollow-core anti-resonant optical fibers caused by mismatched mode fields and structural dimensions, an embodiment of the present invention provides an optical fiber mode field...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com