Chamber scraper structure, anilox roller coating oil supply device and coating machine thereof

An oil supply device and anilox roller technology, applied in the field of coating machines, can solve problems such as difficulty in ensuring uniform compression of scrapers, complex structure and operation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with specific embodiments.

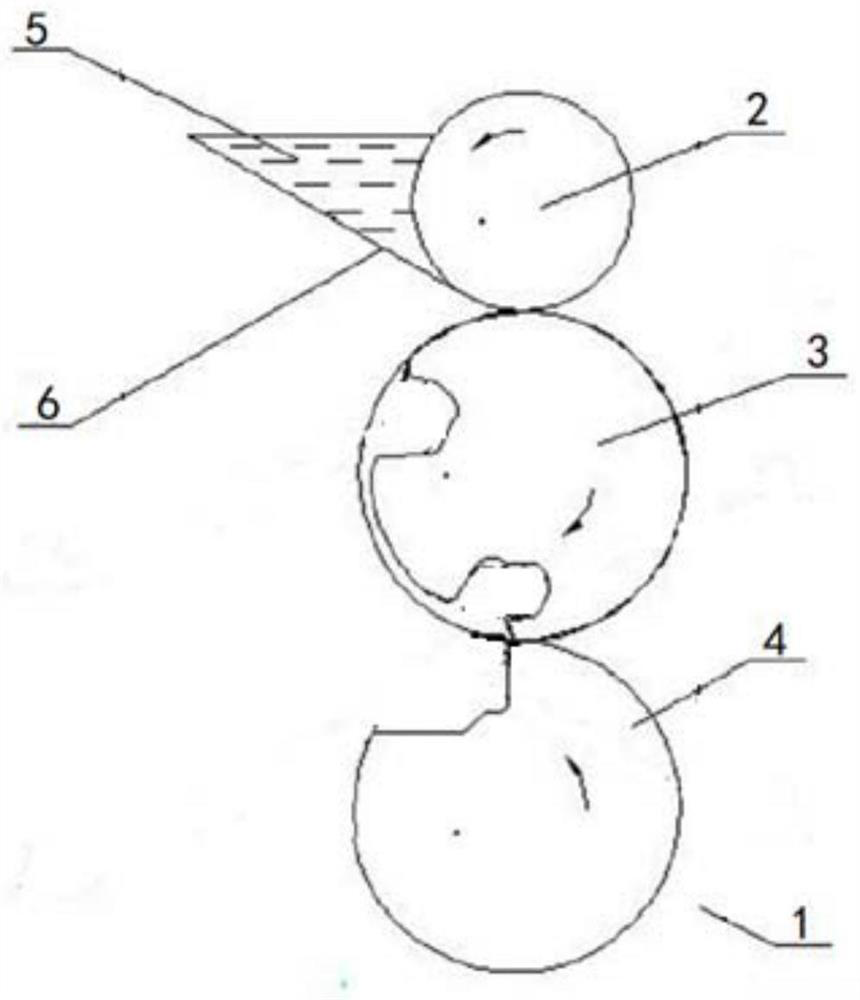

[0029] Such as figure 1As shown, the existing coating machine structure mainly includes a frame 1, anilox roller 2, rubber roller 3, bottom roller 4 and a chamber 5 for storing paint; wherein, the frame 1 is sequentially arranged from top to bottom 1. The anilox roller 2, the rubber roller 3 and the bottom roller 4, the chamber 5 is in contact with the anilox roller 2 to provide coating for the anilox roller 2, and the scraper 6 is set at the contact between the chamber 5 and the anilox roller 2, It can scrape off the excess paint stuck on the surface of the anilox roller 2, and leave the paint between the anilox gaps on the anilox roller 2; The paint is evenly transferred to the rubber roller 3; the bottom roller 4 and the rubber roller 3 rotate synchronously, and drive the sheet to be coated between the two rollers, so that the paint on the rubber roller 3 can be applied...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap