Connector and a connector system

一种连接器、终端接头的技术,应用在连接、连接装置的零部件、运输和包装等方向,能够解决短路终端7缺少支撑、不能够防止向后移动、位置和锁定突出部分的个数在结构限制等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

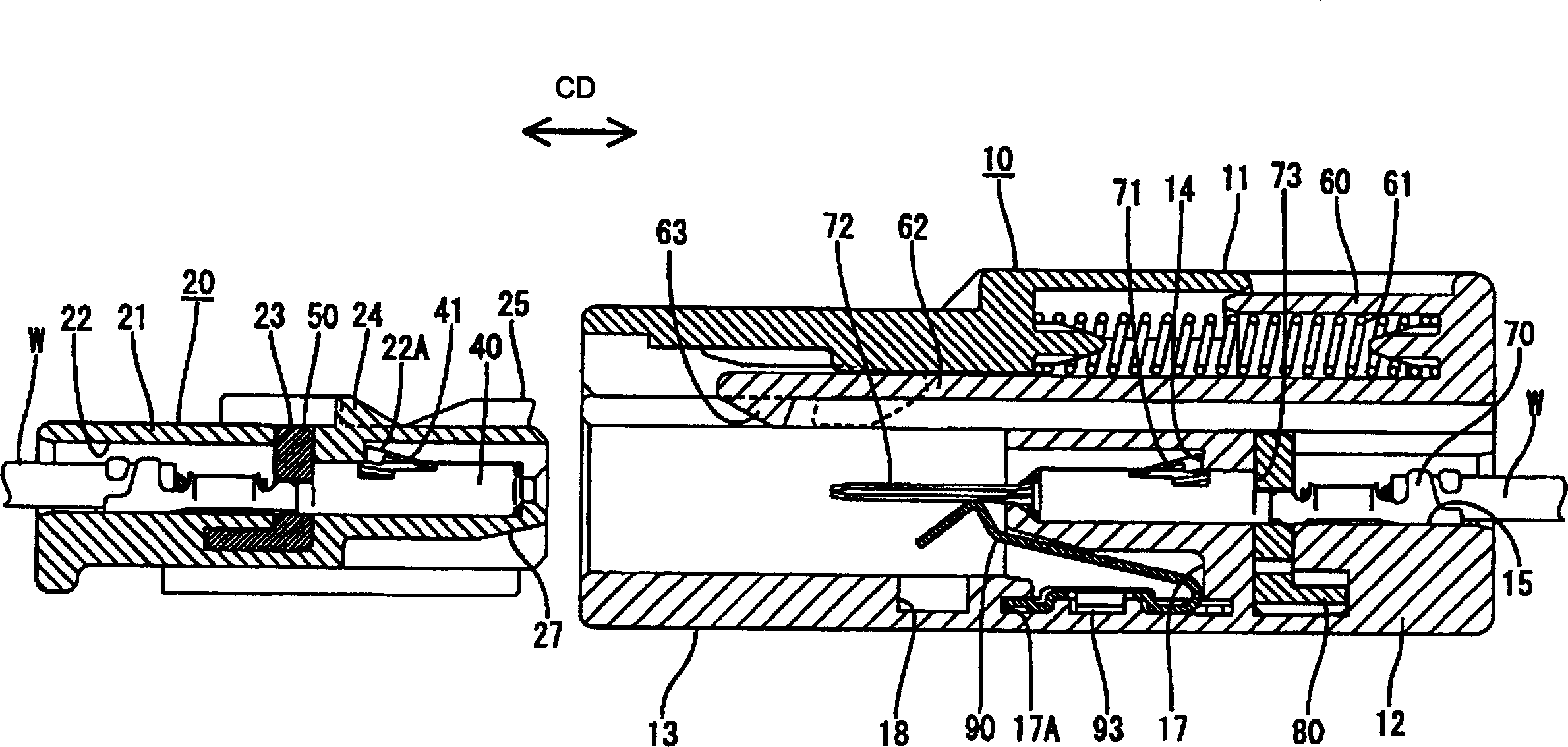

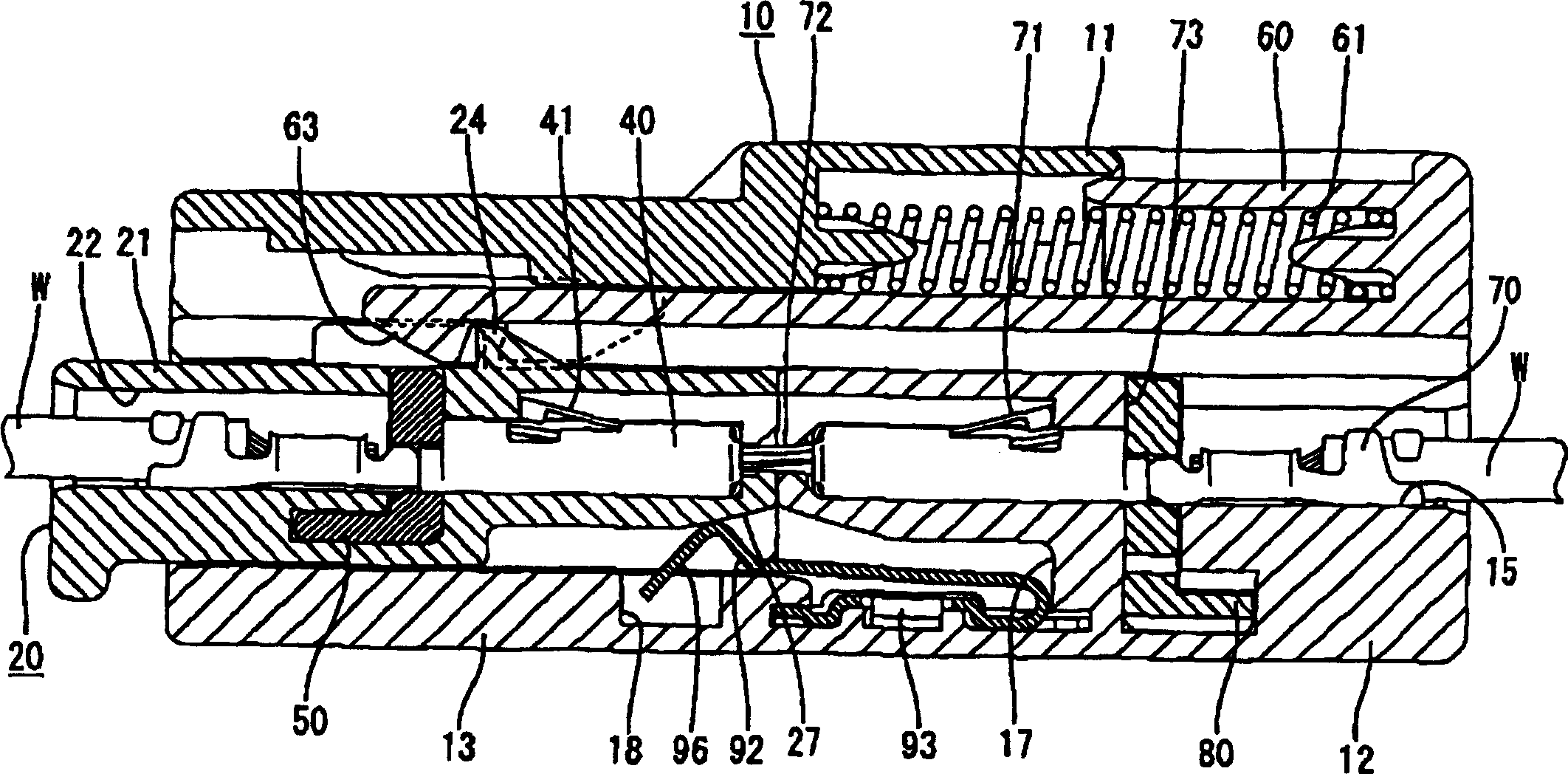

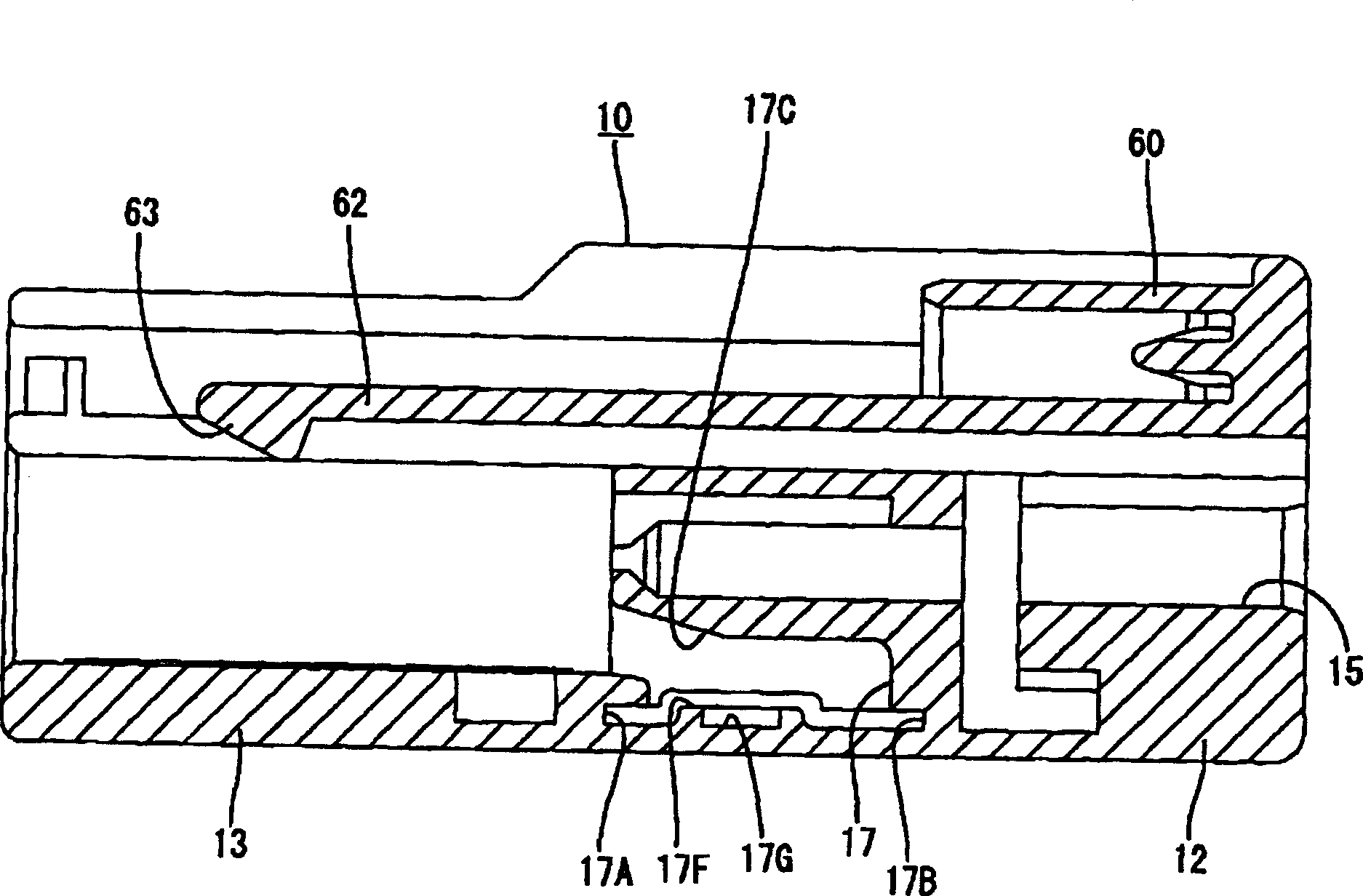

[0054] refer to figure 1-8 The first preferred embodiment of the present invention will be described. A connector used, for example, in an air bag actuation circuit mounted in a motor vehicle is described in the first preferred embodiment. The connector is preferably a male connector 10 and forms at least a part of the airbag actuation circuit by connecting with a female connector 20 (corresponding to a preferred mating connector). In the following description, the mating side of the male and female connectors 10, 20 is referred to as the front side.

[0055] First, the female connector 20 will be described. The female connector 20 has a female housing made of synthetic resin, for example, and its shape is substantially as figure 1 The one on the left is block-shaped, and one or more (preferably a plurality (three in this embodiment)) cavities pass through the female housing 21 substantially side by side along the front-rear direction. One or more female terminal fittings ...

no. 2 example

[0075] Figure 9 (B) shows a second preferred embodiment of the present invention. Although the second embodiment is the same as the first embodiment in that the anchor mounting hole 16 is formed in one side surface of the male housing 11 extending along the connecting direction, it is the same as the first embodiment in the bottom plate 94 of the short-circuit terminal 90 and The receiving portion 17E is different in structure.

[0076] Specifically, the shorting terminal 90 of the second embodiment has an inclined portion 100 inclined upward or inward toward a deformation space from one end of the bottom plate 94 (the side where the folded portion 95 is placed) to the other end.

[0077] The inclined portion 100 has a pointed portion 100A at a position close to the other end of the bottom plate 94 and a locking portion 93 formed at a central position thereof. The engaging piece 98 preferably extends substantially horizontally (connection direction CD) from the pointed port...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com