Multi-flavoured hot beverage dispenser

a dispenser and multi-flavour technology, applied in beverage vessels, special dispensing means, packaging, etc., can solve the problems of operator turning away customers, increasing the return of providing an extra flavour, and not being able to justify the added revenue obtained

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

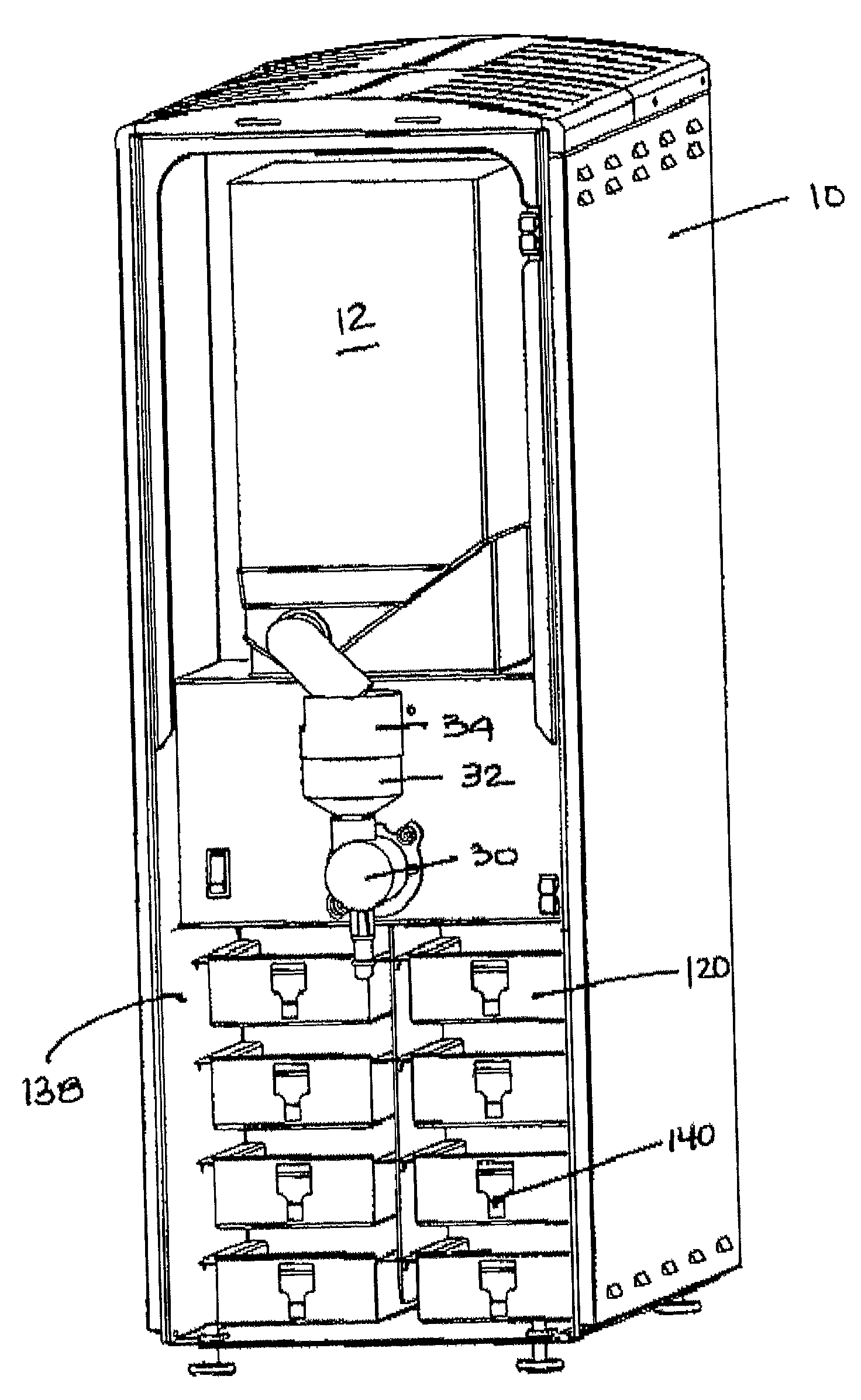

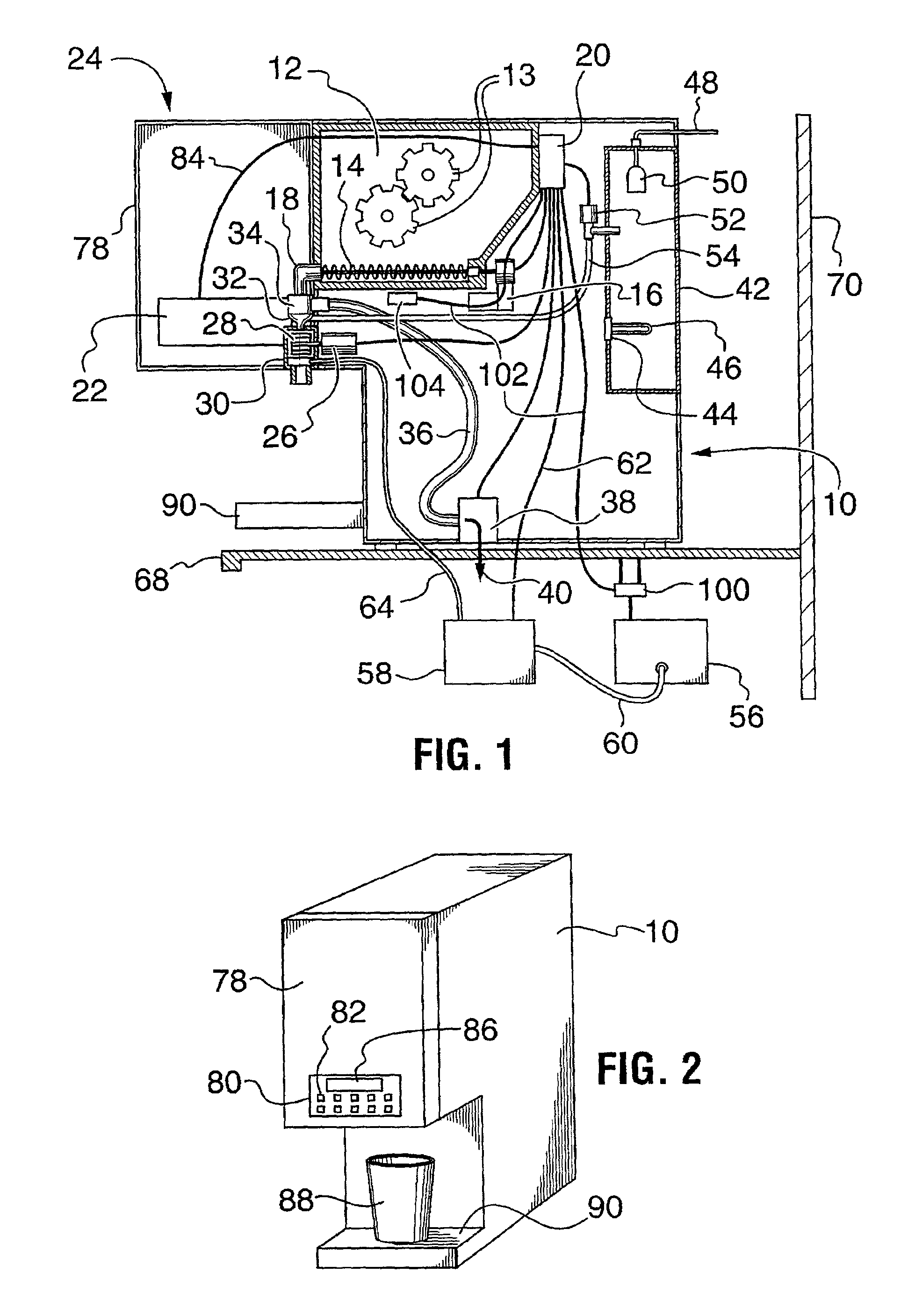

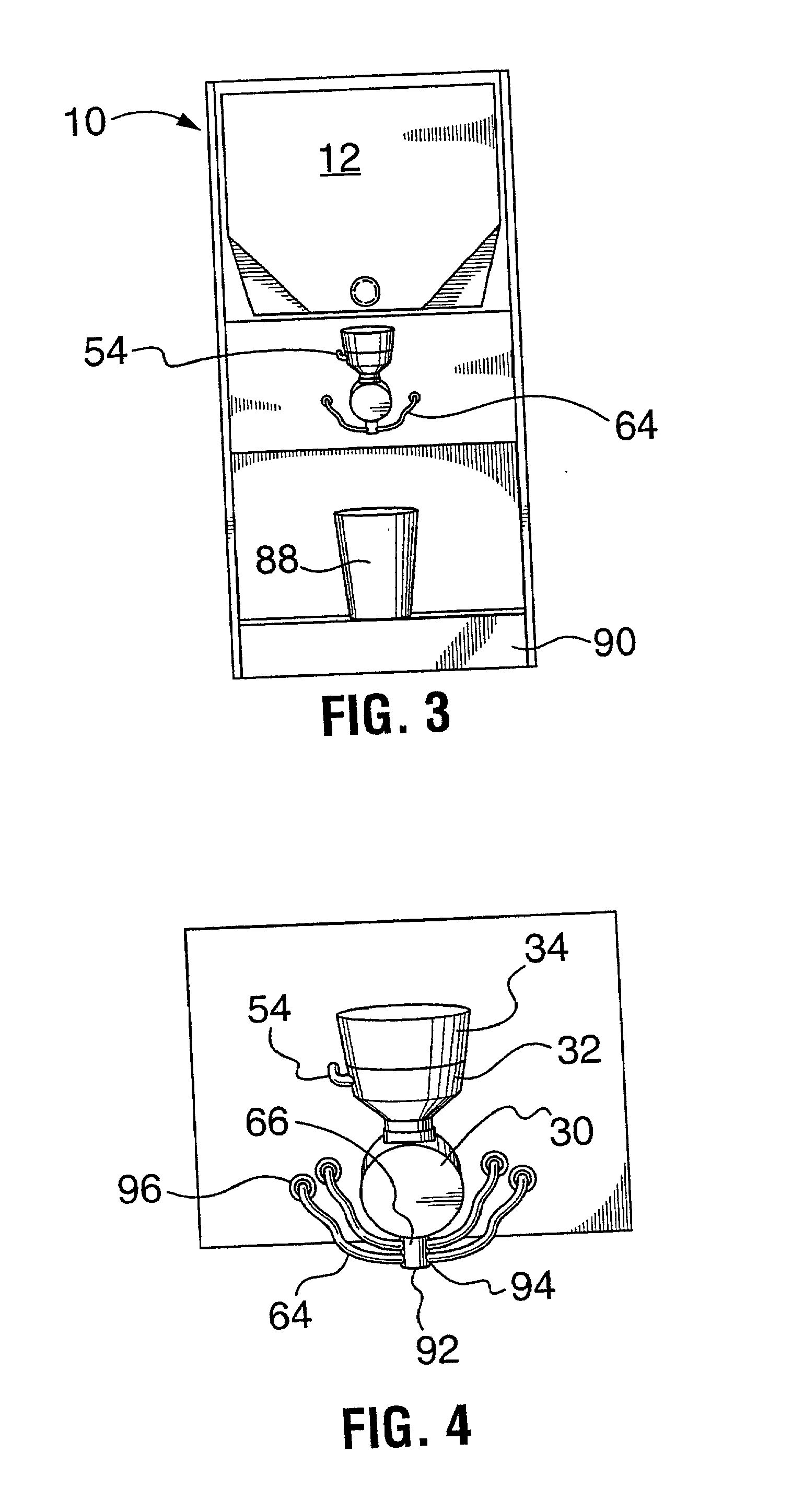

[0042] FIG. 1 shows a partial cross-sectioned side view of a preferred embodiment of a multi-flavoured hot drink dispenser constructed in accordance with the principles of the present invention. The dispenser is generally depicted by reference numeral 10 and uses a base powder dispensing system comprising a hopper 12 to hold a base powder. Typically, the base powder will be an unflavoured base powder and the flavour of the hot drink that will be produced will be provided by a flavouring syrup. It will be understood, however, that the base powder may also be a hot chocolate drink powder that is further flavoured by a selected flavouring syrup. The hopper 12 has been cross-sectioned in this view to show internal components. Hopper 12 contains an auger drive 14 which is activated by auger motor 16 to dispense powder out of the powder dispensing nozzle or hopper dispenser outlet 18. Auger motor 16 is controlled and powered by main control board 20. Main control board 20 is electrically ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com