Package for shipping and storage of panel products

a panel product and packaging technology, applied in the field of packaging materials for shipping flat panel products, can solve the problems of increasing labor difficulty and shipping expenses, difficult packaging and shipping of stone and various composite materials, and high labor intensity of packaging process,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

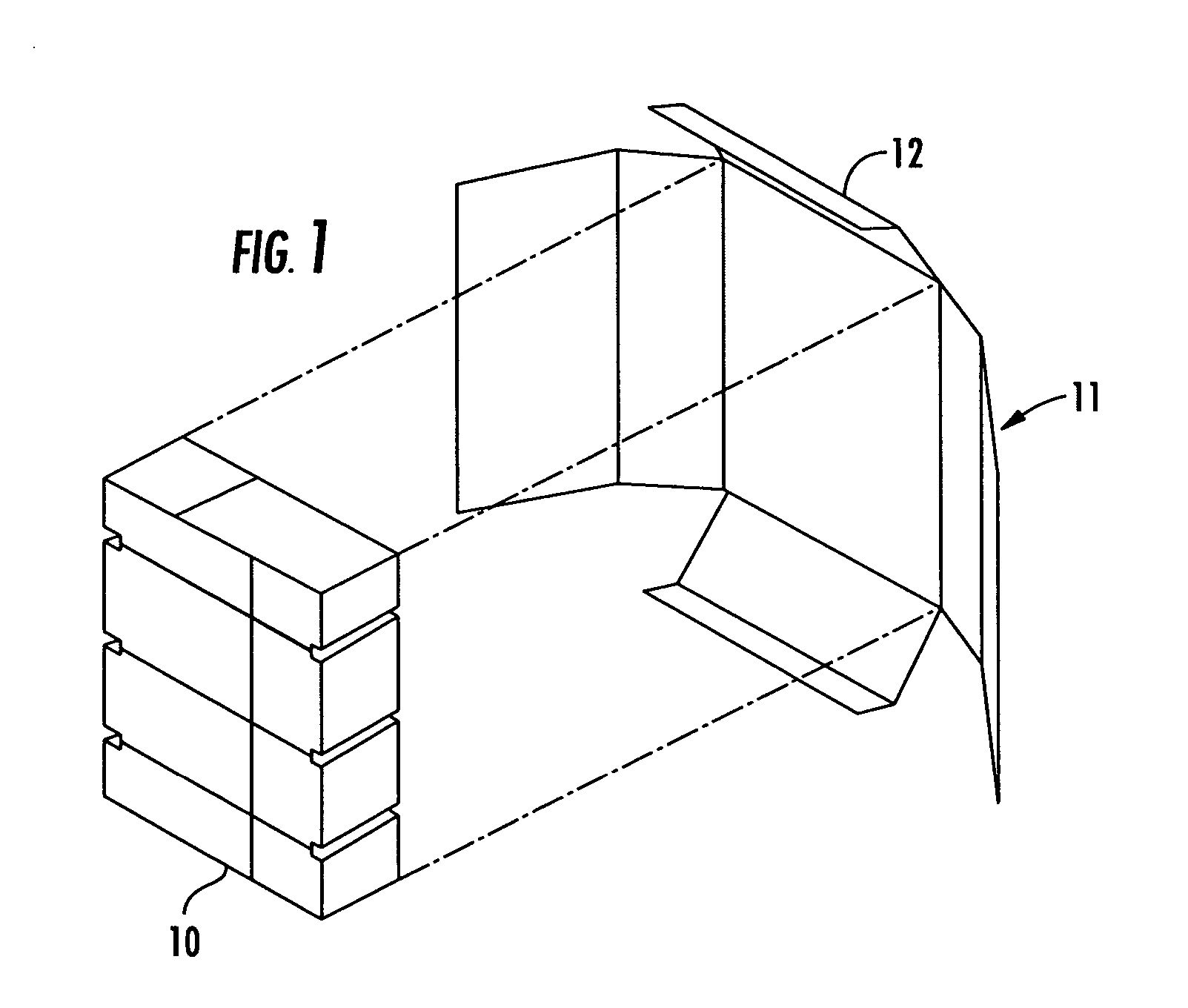

[0018] Referring now to the figures and more particularly to FIG. 1, a shipping package 11 constructed in accordance with the present invention is shown. The shipping package 11 comprises a protected panel product 10 enclosed inside of an outer shipping packaging 12. The protected panel product 10 and shipping packaging 12 protect the product from damage during shipping and further provide a location for mounting a shipping label.

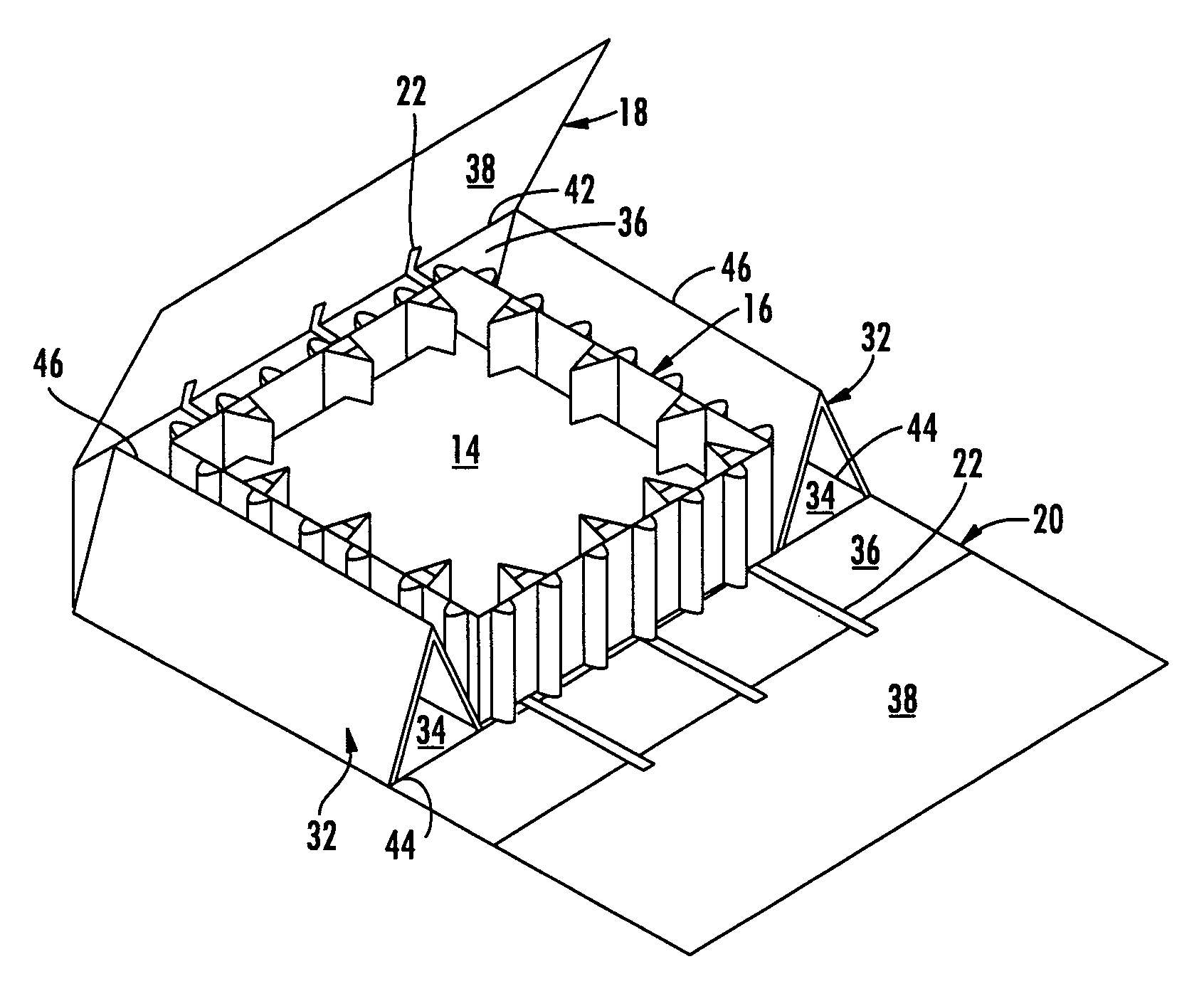

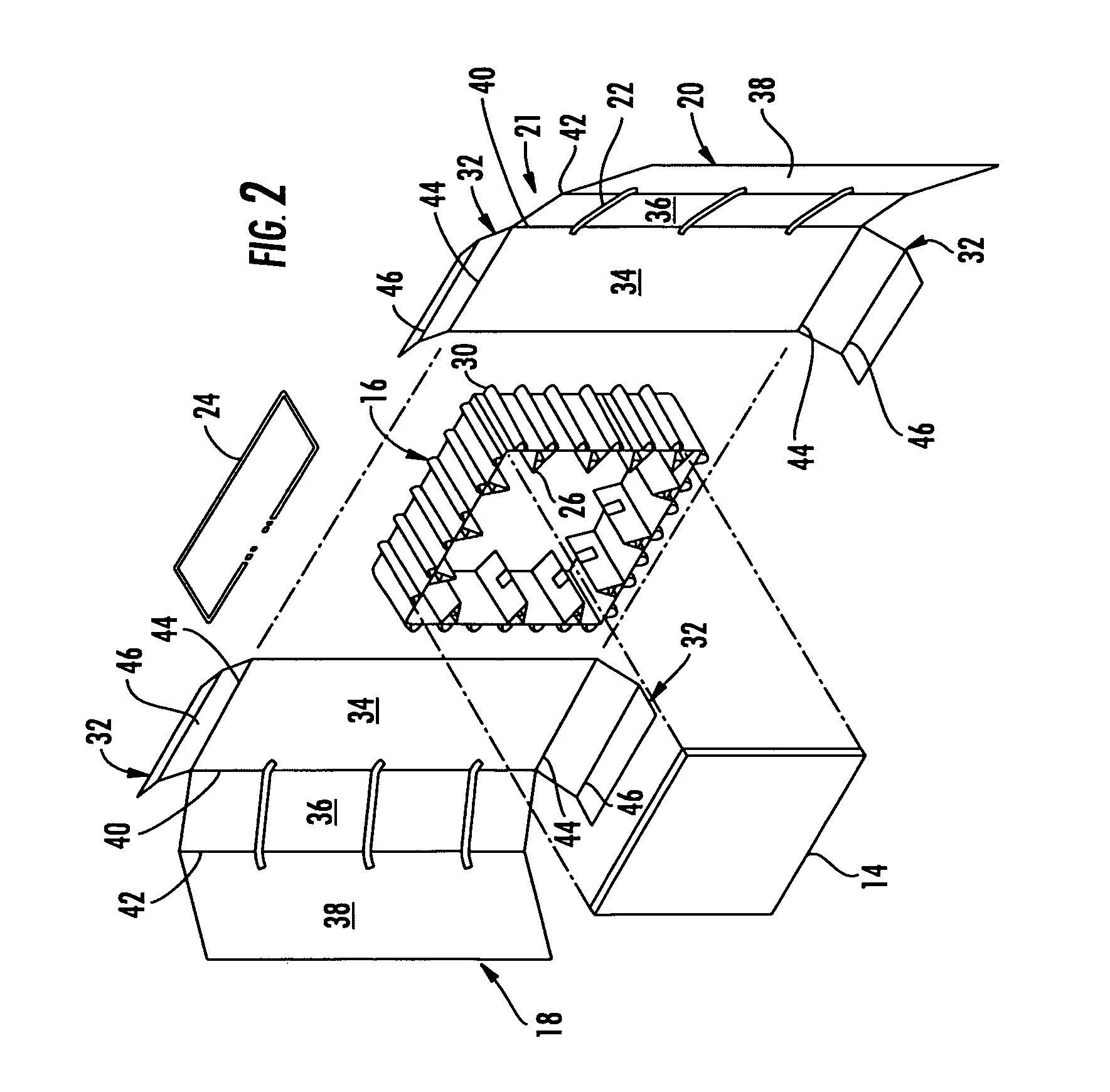

[0019] Referring now to FIG. 2, the protected panel product 10 is a sheet or flat panel product 14 which is enclosed peripherally about its outer circumferential edge in a length of inner protective packaging material 16, which is itself enclosed in an outer protective package 21. The outer protective packaging material 21 is preferably, as shown here, a size-adjustable box constructed of two protective panels 18 and 20 which can be “telescoped” longitudinally to adjust to various lengths of panel products 14, as described below. The lateral dimension of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com