Automatic hanging hook system

a technology of hanging hooks and hooks, which is applied in the field of processing food products, can solve the problems of difficult transfer of food products from conveyor hooks to rack hooks, unsatisfactory loop types, and difficult processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] While the invention may be susceptible to embodiments in different forms, there are shown in the drawings, and herein will be described in detail, specific embodiments with the understanding that the present disclosure is to be considered an exemplification of the principles of the invention, and is not intended to limit the invention to that as illustrated and described herein.

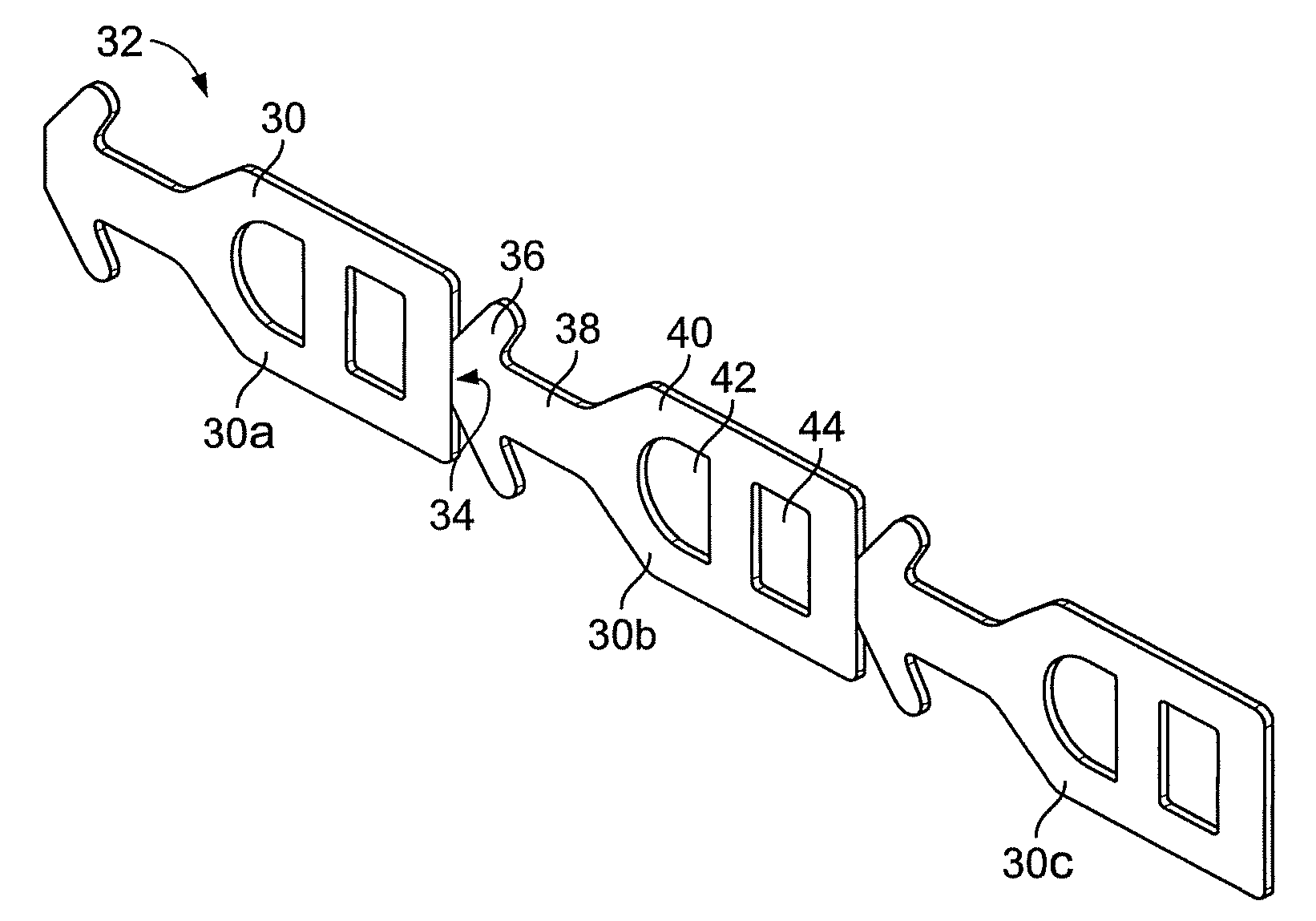

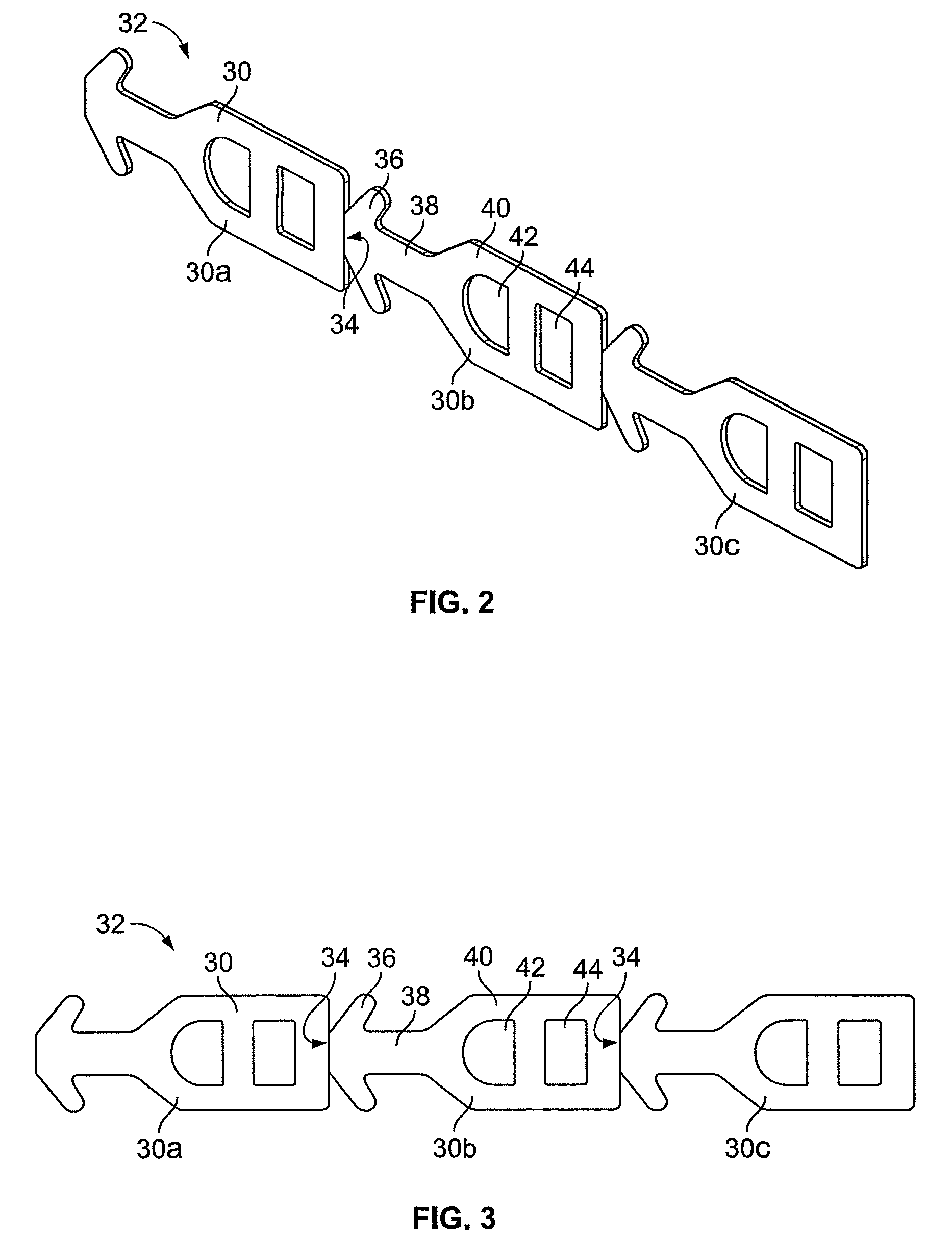

[0025] The loop 30 of a first embodiment of the present invention is shown in perspective view in FIG. 2 and in plan view in FIG. 3. Loop 30 is preferably manufactured in a chain 32 of individual pieces 30a, 30b, 30c, etc. Perforations 34 between each loop 30a, 30b, 30c, etc. are created in the manufacturing process, so that each individual loop 30 breaks off easily from the chain 32. Accordingly, chain 32 is preferably on a reel. The reel is mounted on an automated netter and each individual loop 30a, 30b, 30c, etc., is snapped off the chain 32 when it becomes the leading loop 30.

[0026] Loop 30 has ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap