Portable form and method for using same for concrete strike-off

a technology of concrete and strike-off, which is applied in the field of portable devices, can solve the problems that the finished surface produced by the so-called “wet screed” method of concrete slab construction typically does not conform to the desired grade, and achieves the effect of simplifying positioning and establishmen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

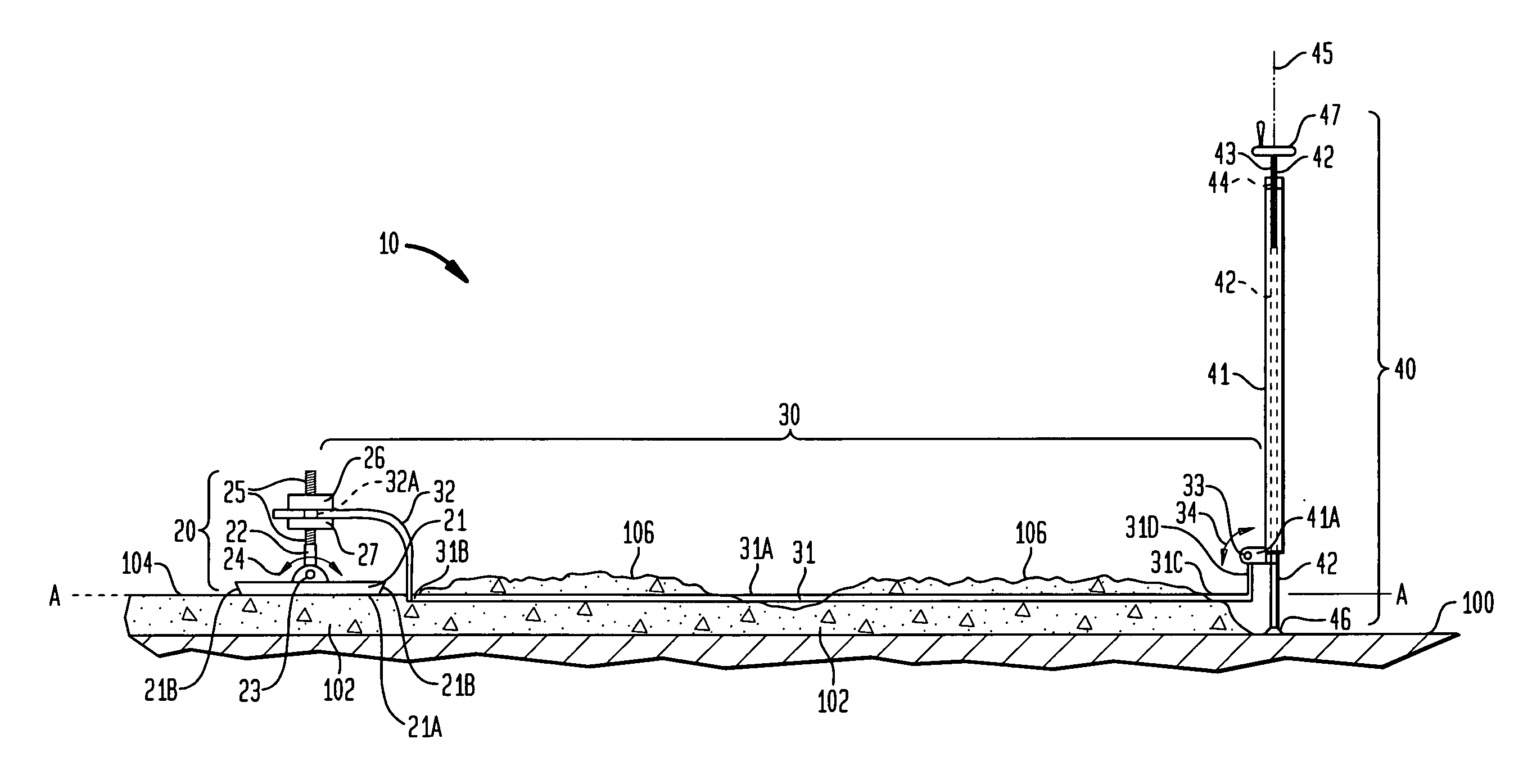

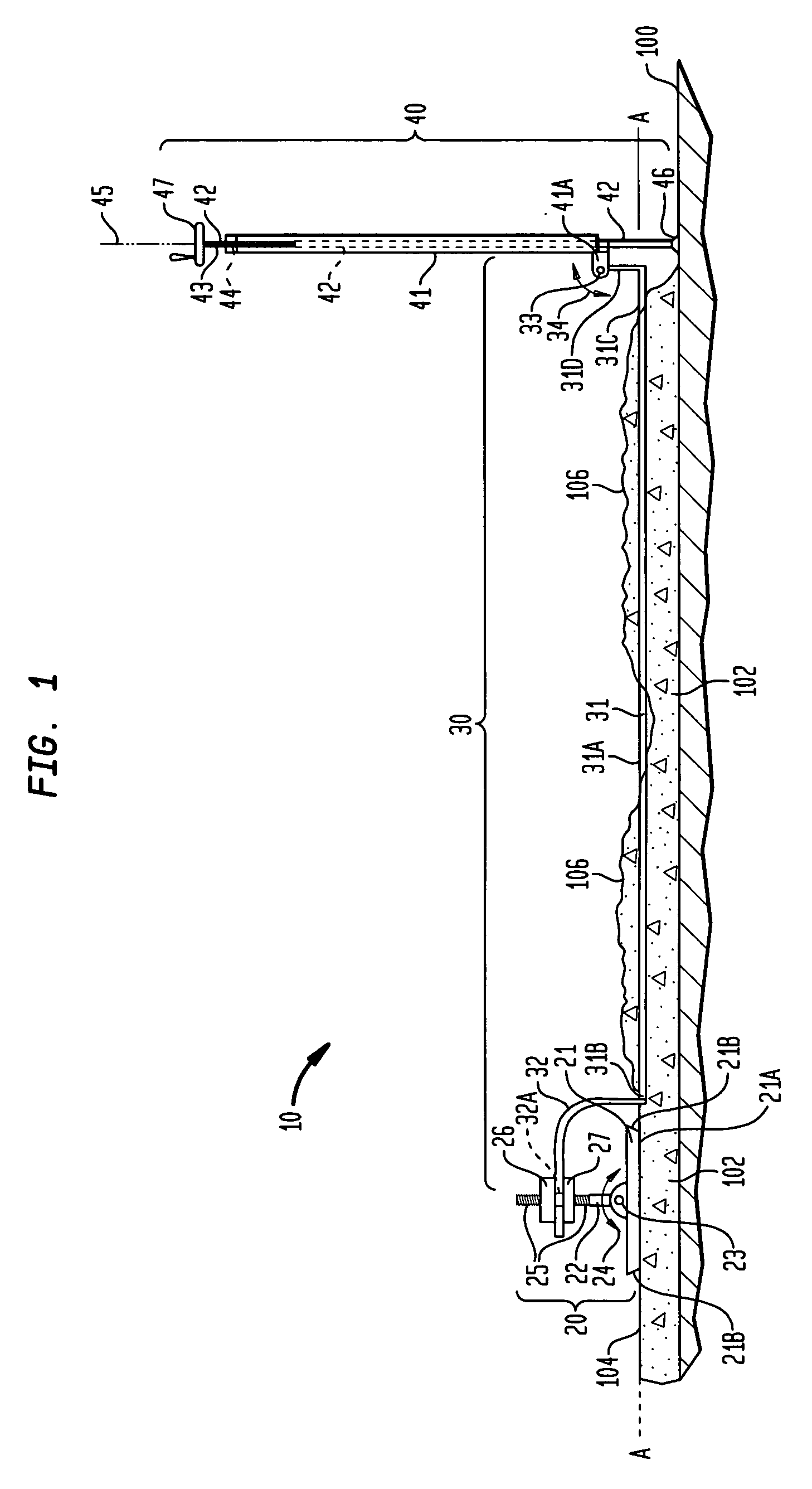

[0019] Referring now to the drawings, and more particularly to FIG. 1, an apparatus for defining a form in a concrete strike-off operation is shown and is referenced generally by numeral 10. Apparatus 10 is illustrated in an operational set-up in which an underlying base structure is referenced by numeral 100, wet or plastic concrete is referenced by numeral 102, a finished surface of the plastic concrete at desired grade A-A is referenced by numeral 104, and an unfinished surface of the plastic concrete is referenced by numeral 106.

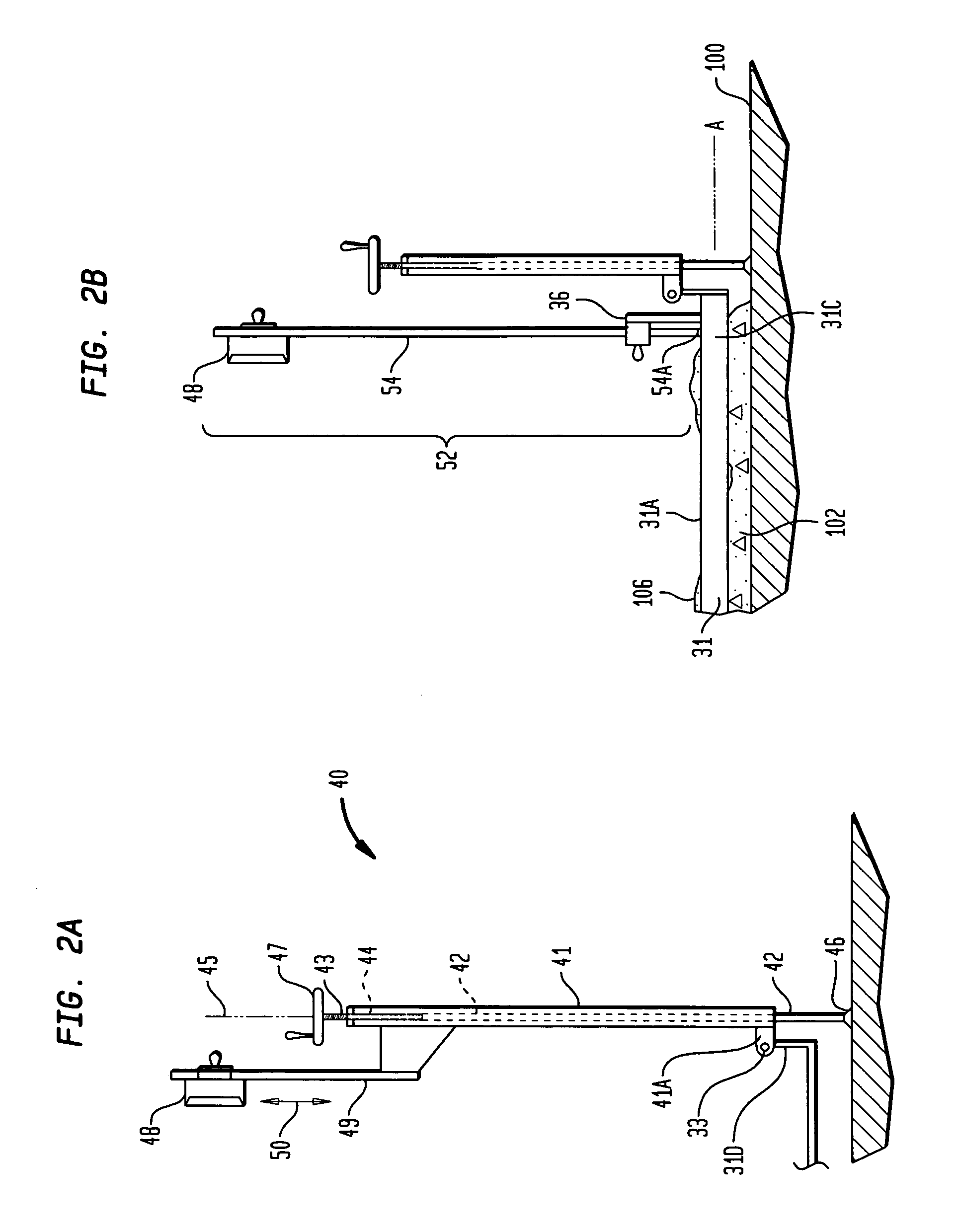

[0020] Apparatus 10 includes three main assemblies that are coupled to one another. The assemblies are a pan assembly 20, a form assembly 30, and a support assembly 40. In general, pan assembly 20 floats on finished surface 104 while providing the means to set the elevation of one end of form assembly 30. Support assembly 40 rests on underlying base structure 100 while providing the means to set the elevation of another end of form assembly 30 by, for e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com