Bin

a technology for bins and bin covers, applied in the field of bins, can solve the problems of undesirable noise, undesirable noise, and bins with bin covers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

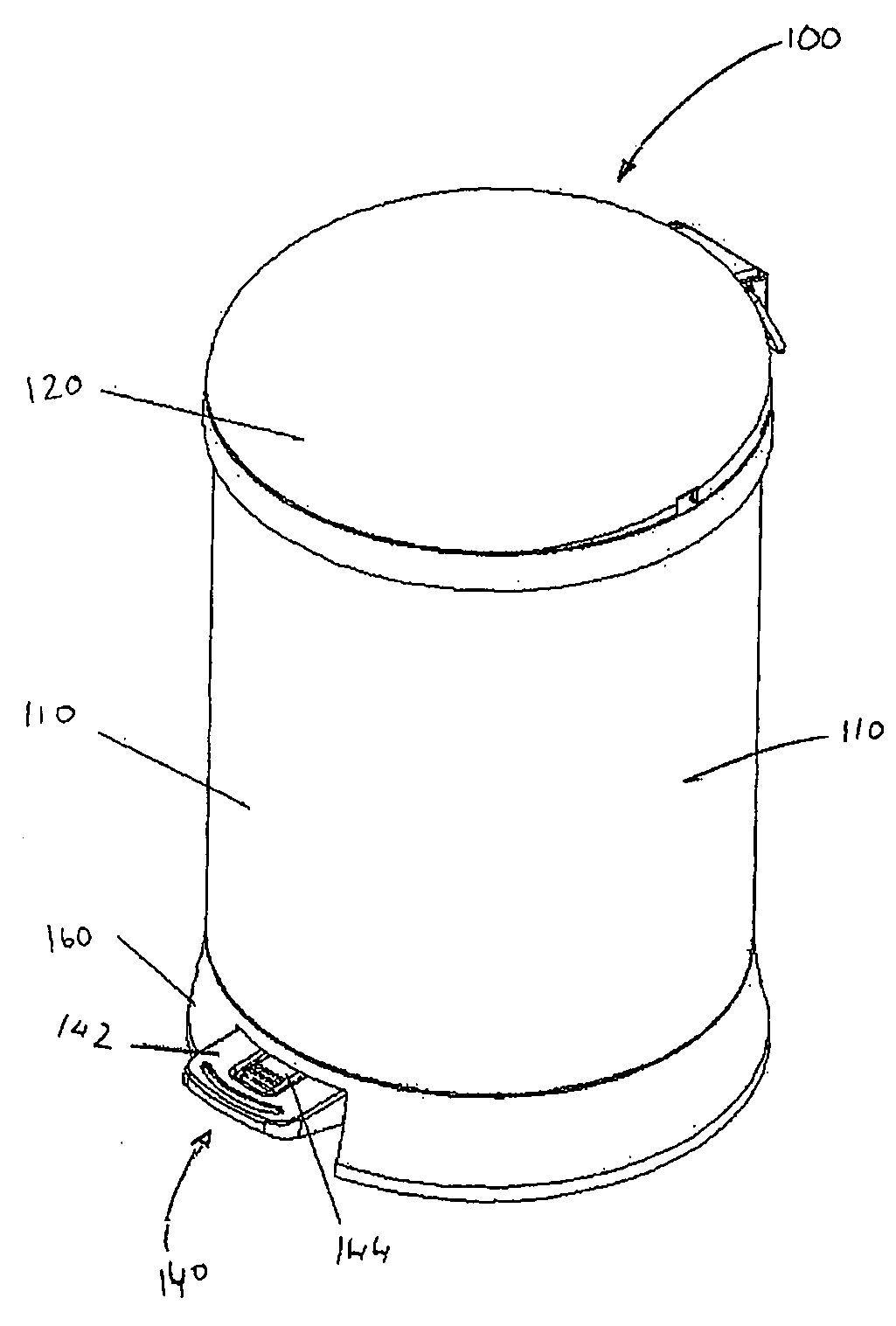

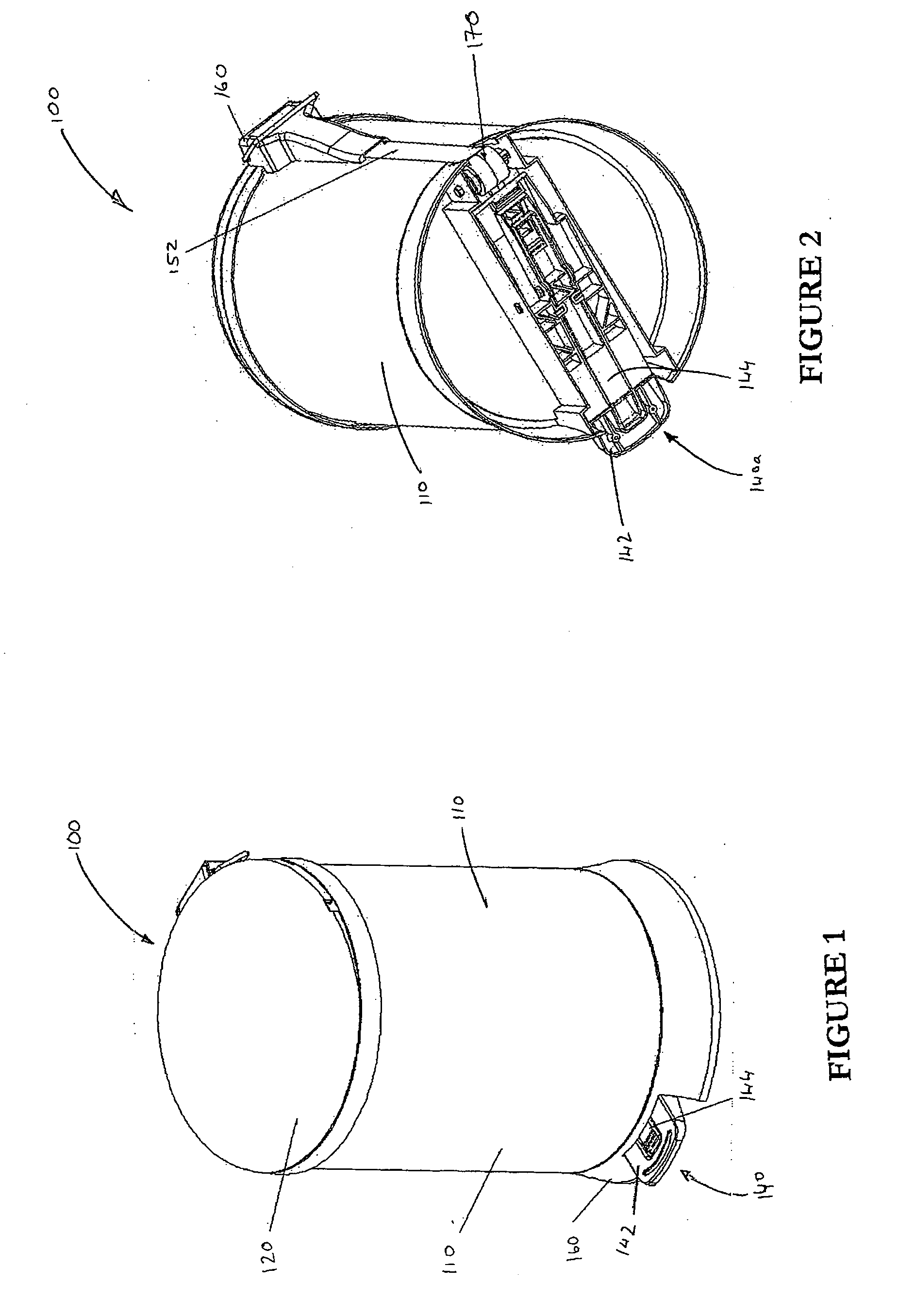

[0331]With reference to the accompanying figures, a bin according to a first aspect of the invention is generally indicated by the numeral 100.

[0332]In one embodiment according to the invention now described, there is provided a bin 100, suitable for the retention of rubbish. The bin 100 comprises a container 110, and a lid 120 which is pivotable about an axis 122 to move between an open position (as shown in FIGS. 8, 9, 19, and 20) in which items, such as domestic rubbish, are received into the container 110, and a closed position (as shown in FIGS. 1, 7, 10, 11, 12, 13, 16, 17, 18, 21 and 22) in which access to the container is sealed by the lid 120, preferably by an airtight seal to prevent smells escaping. The bin 100 further comprises a lid actuating device 130 for moving the lid 120 between the open position and closed positions.

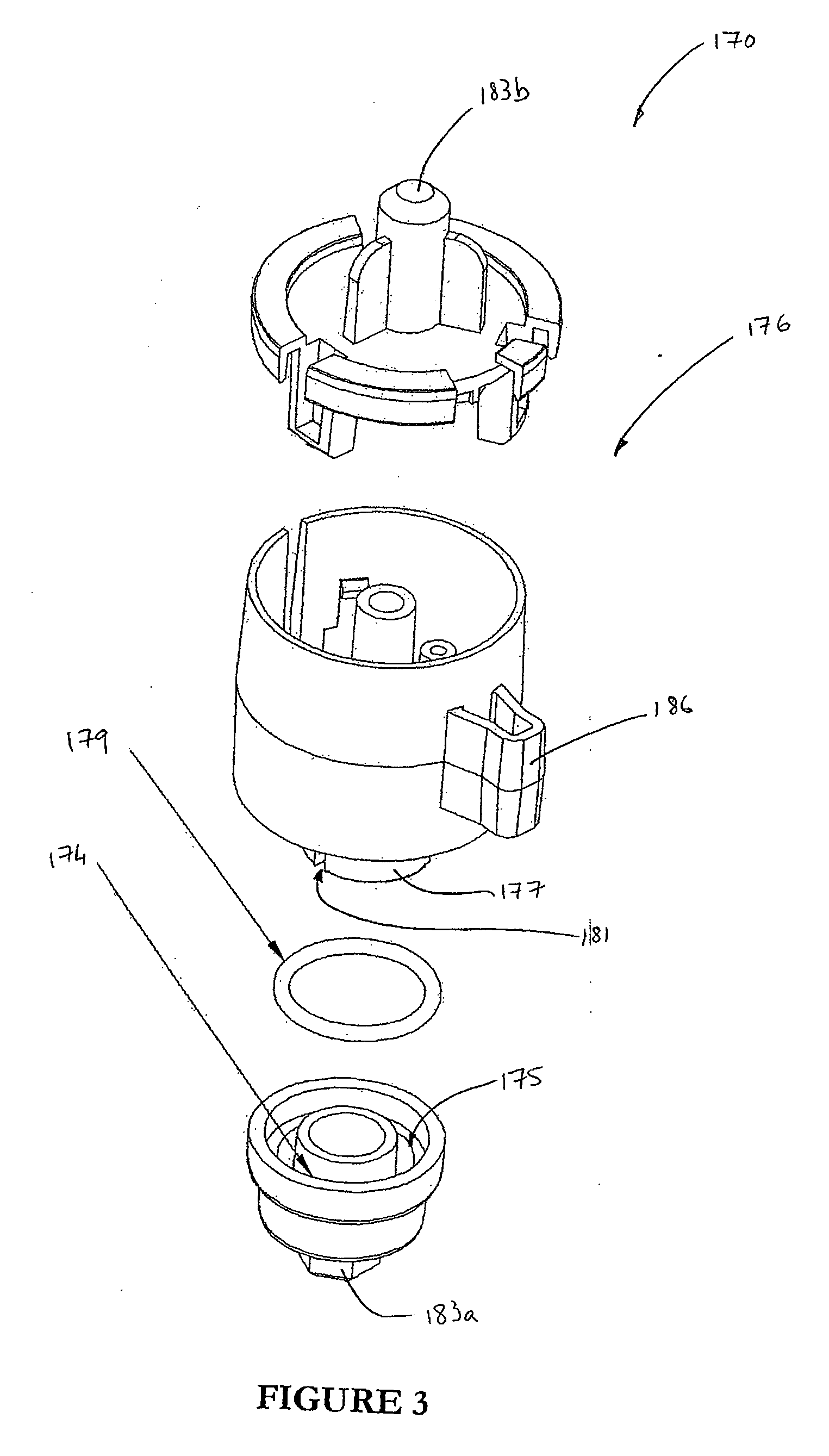

[0333]The lid actuating device 130 includes an actuator mechanism 140, shown in this embodiment as a foot pedal mechanism 140a, actuatable by a user (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com