Process for the Separation and Purification of Hafnium and Zirconium

a technology of hafnium and zirconium, which is applied in the direction of separation processes, titanium compounds, solvent extraction, etc., can solve problems such as the discontinuity of plant operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

1.1 Organic Products

1.1.1 Zirconium and Hafnium Source

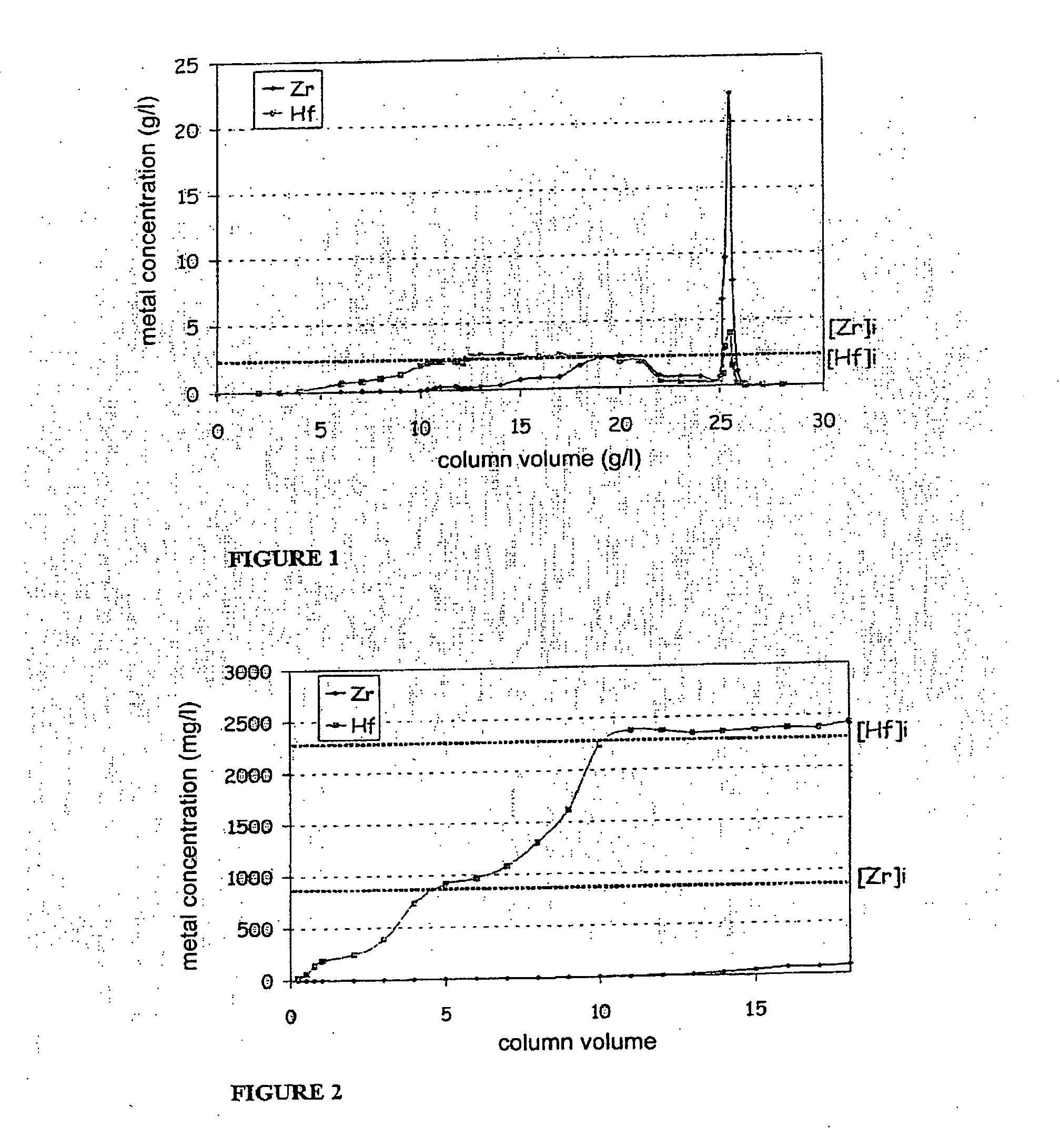

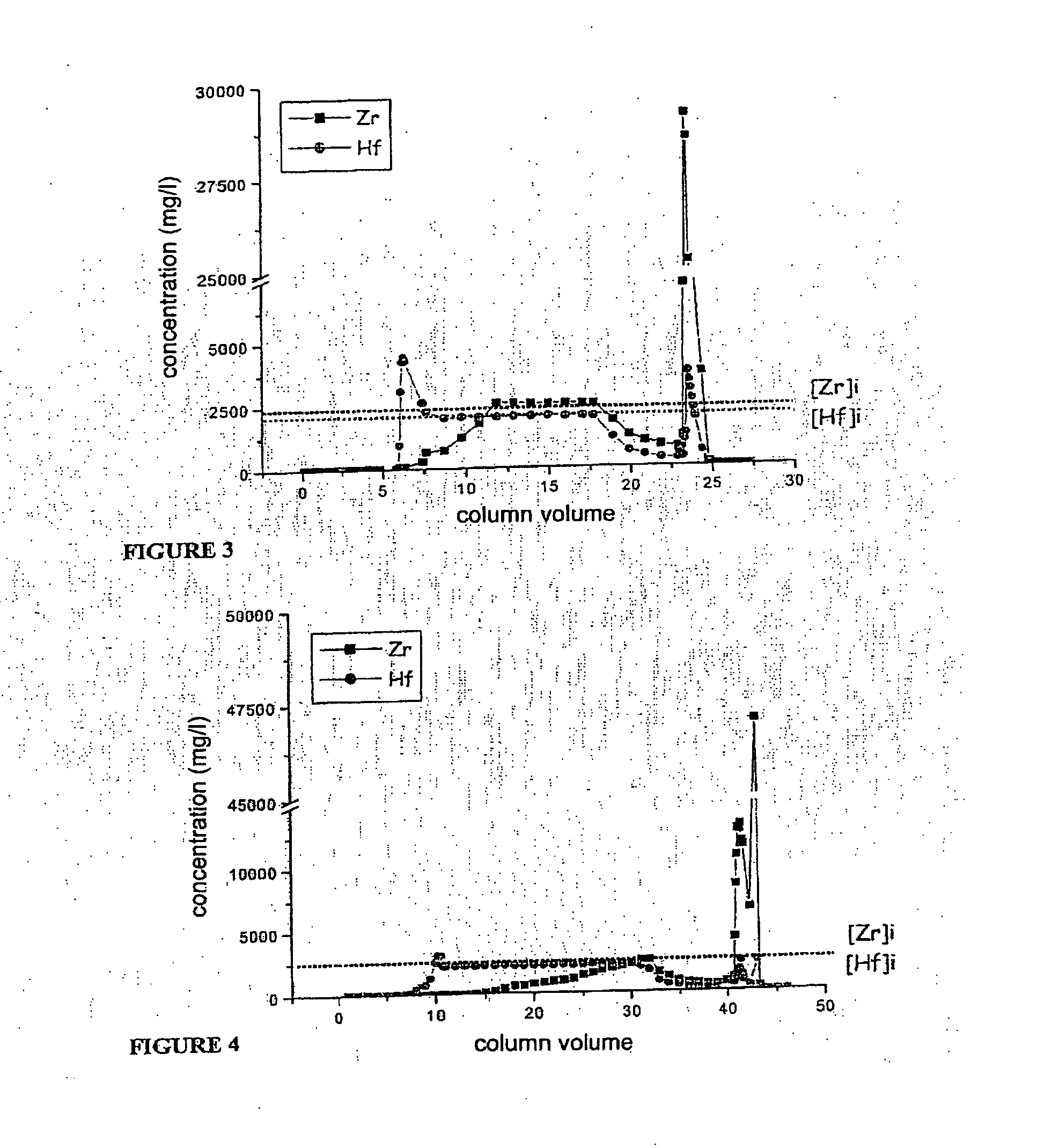

[0110] The zirconium / hafnium separation studies were carried out, on the one hand, from zirconium and hafnium tetrachlorides obtained after carbochlorination (Zr / Hf ratio by weight: 97.5 / 2.5), then extractive distillation.

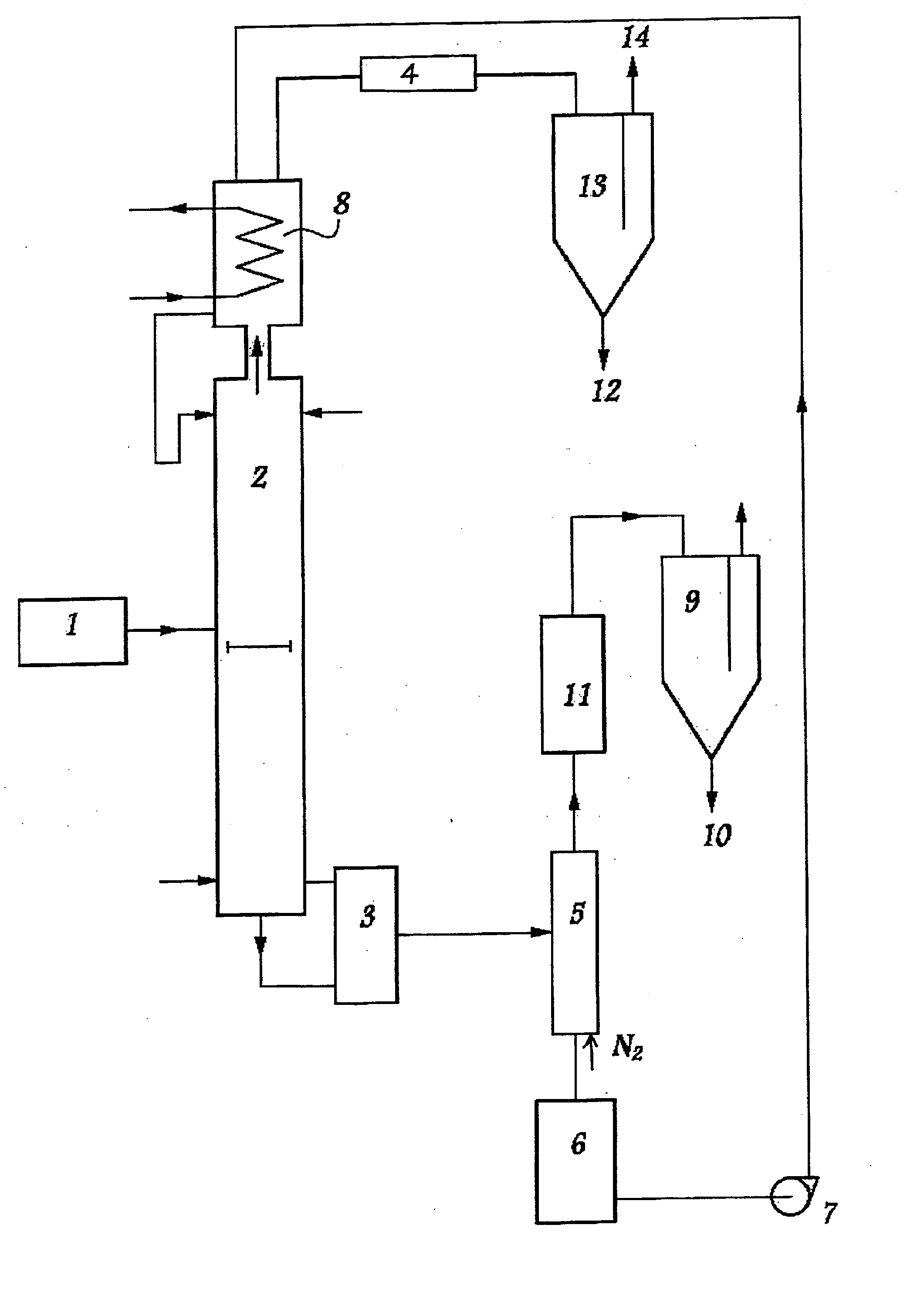

[0111]FIG. 6 illustrates the equipment in which the extractive distillation leading to the separation of ZrCl4 and HfCl4, according to the teaching of FR-A-2 250 707 and FR-A-2 629 360, is carried out.

[0112] The installation comprises a means 1 for feeding a distillation column 2, with zirconium tetrachloride vapours containing hafnium tetrachloride (temperature between 430 and 550° C.). A pump 7 upwardly circulates the extraction solvent according to the invention in the distillation column, in a counter-current to the stream of the zirconium and hafnium tetrachloride vapours. When the circuit is closed, this solvent passes through the absorber 8, the column 2, the boiler 3, the stripping column 5 and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pressure | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com