Pivot joint

A pivoting and pivoting point technology, applied in the field of pivoting joints, can solve the problems of decreased positioning accuracy, non-spherical parts, cannot be replaced cheaply, etc., to achieve the effect of increasing lifespan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

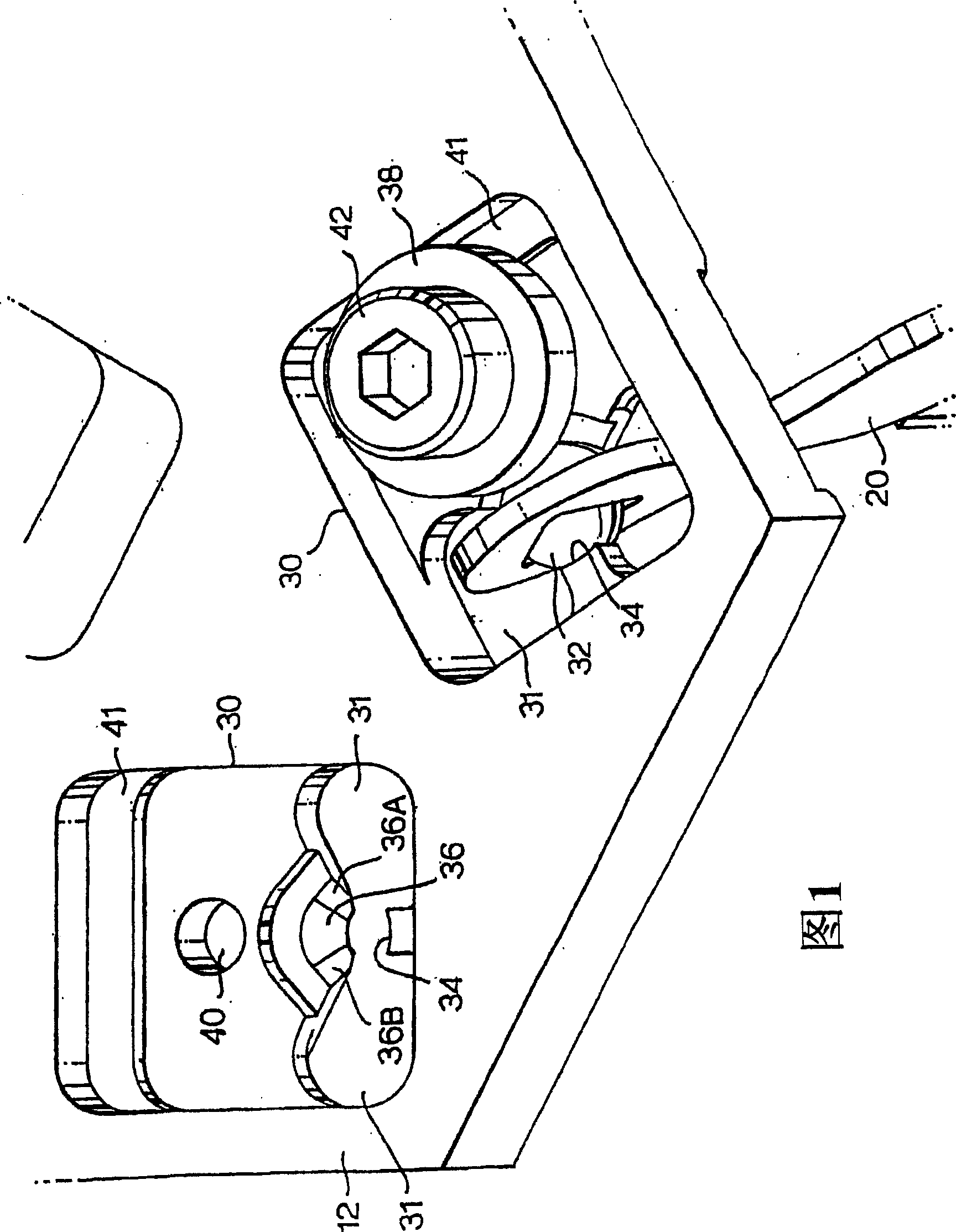

[0022] Figure 1 is an isometric view of two pivot joints. The first structure consists of a seat for a sphere and a sphere. One platform 12 has structured cutouts 30 (seats). The ball 32 of the pivot joint is supported in the cut-out 30 by the surface defined by the edge of the cut-out. In FIG. 1 two cutouts 30 are shown, one with the other parts of the ball joint in situ and one without the other parts of the ball joint.

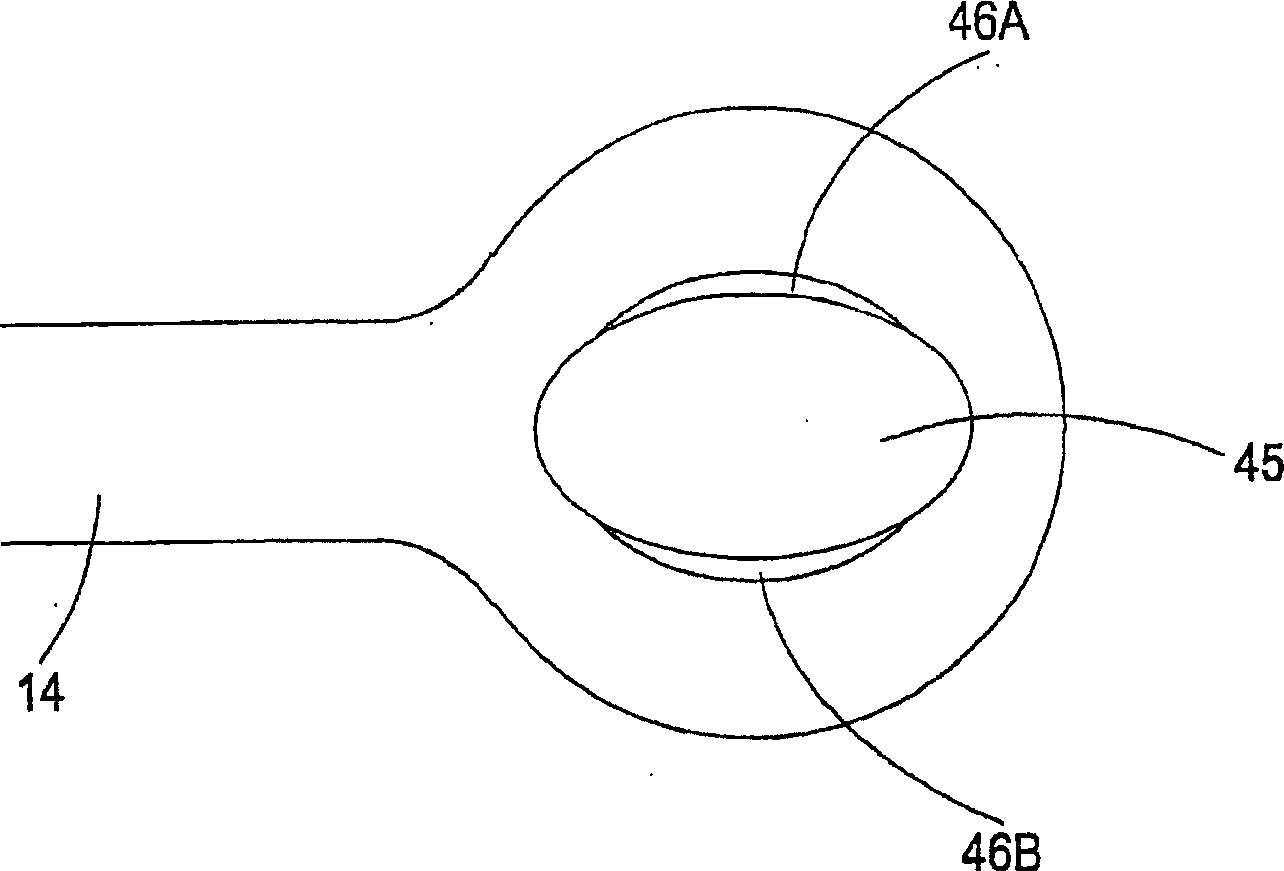

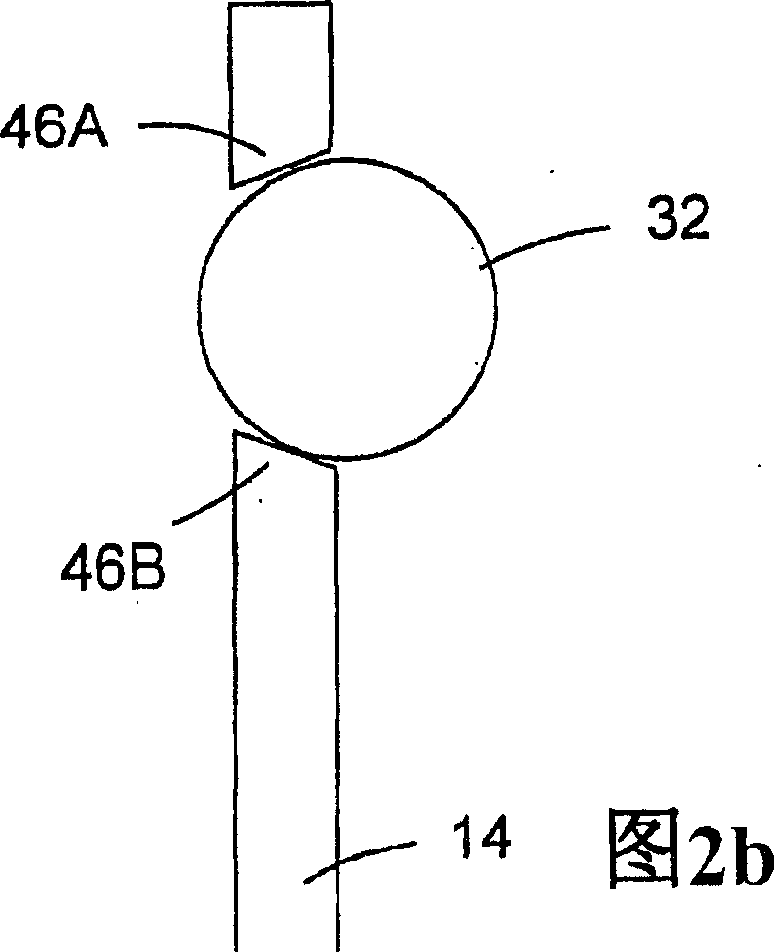

[0023] The ball 32 is supported by two opposing surfaces 34 , 36 of the cutout 30 . The first curved surface 34 is in contact with one side of the ball 32 and the second curved surface 36 is in contact with the lower surface of the ball 32 at two contact points 36A, 36B. The position of the ball 32 is determined by the three contact points 34 , 36A, 36B and a fourth contact point provided by a clamp 38 , 42 . The ball is thus kinematically reproducible in the above-mentioned cutout.

[0024] In this example, the clamp includes a washer 38 and a fixing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com