Fire-resistant and wear-resistant cable and cable processing system

A fire-resistant and wear-resistant, processing system technology, used in insulated cables, cable/conductor manufacturing, cables, etc., can solve the problems of easily exposed conductors on the structural layer, easy to wear on the surface of the cable, affecting the normal operation of the cable, etc. Use time, prolong protection time, reduce possible effects of damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

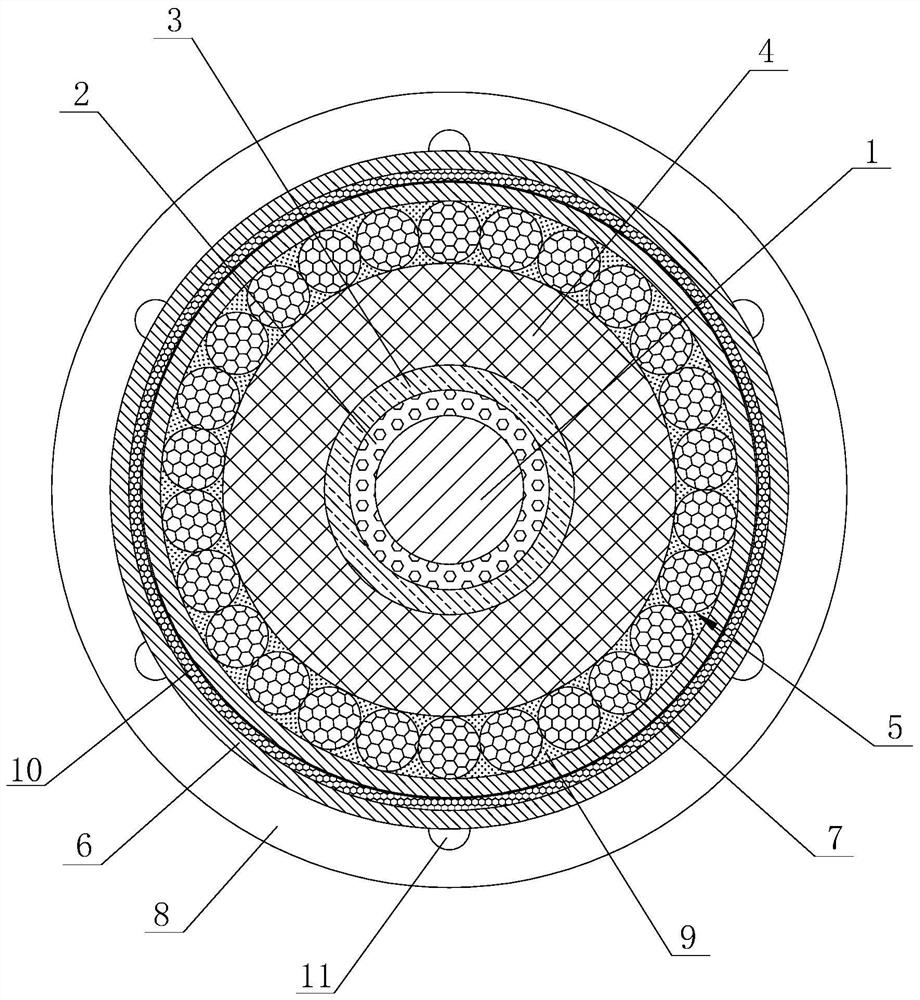

[0046] refer to figure 1 , Embodiment 1 of the present application discloses a fire-resistant and wear-resistant cable, including: an inner layer and an outer layer.

[0047] refer to figure 1 , the inner layer is provided with a conductor 1, an insulating layer 2 and a flame retardant layer 3 sequentially from the inside to the outside.

[0048] refer to figure 1, Conductor 1 is braided copper wire. The insulating layer 2 is made of polyethylene, and the insulating layer 2 covers the outside of the conductor 1 . The flame retardant layer 3 is made of phenolic resin composite material, and the flame retardant layer 3 is coated on the outside of the insulating layer 2 so as to prolong the service time of the cable in case of fire.

[0049] refer to figure 1 , the outer layer is provided with a fireproof layer 4, a protective layer 5 and an outer sheath 6 sequentially from the inside to the outside.

[0050] refer to figure 1 , the fireproof layer 4 is formed by stacking ...

Embodiment 2

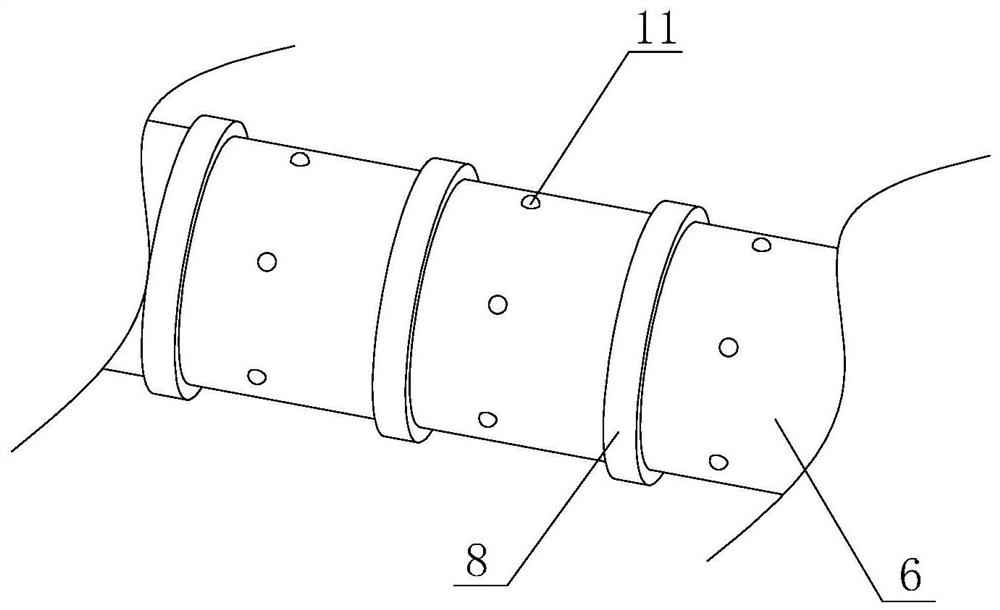

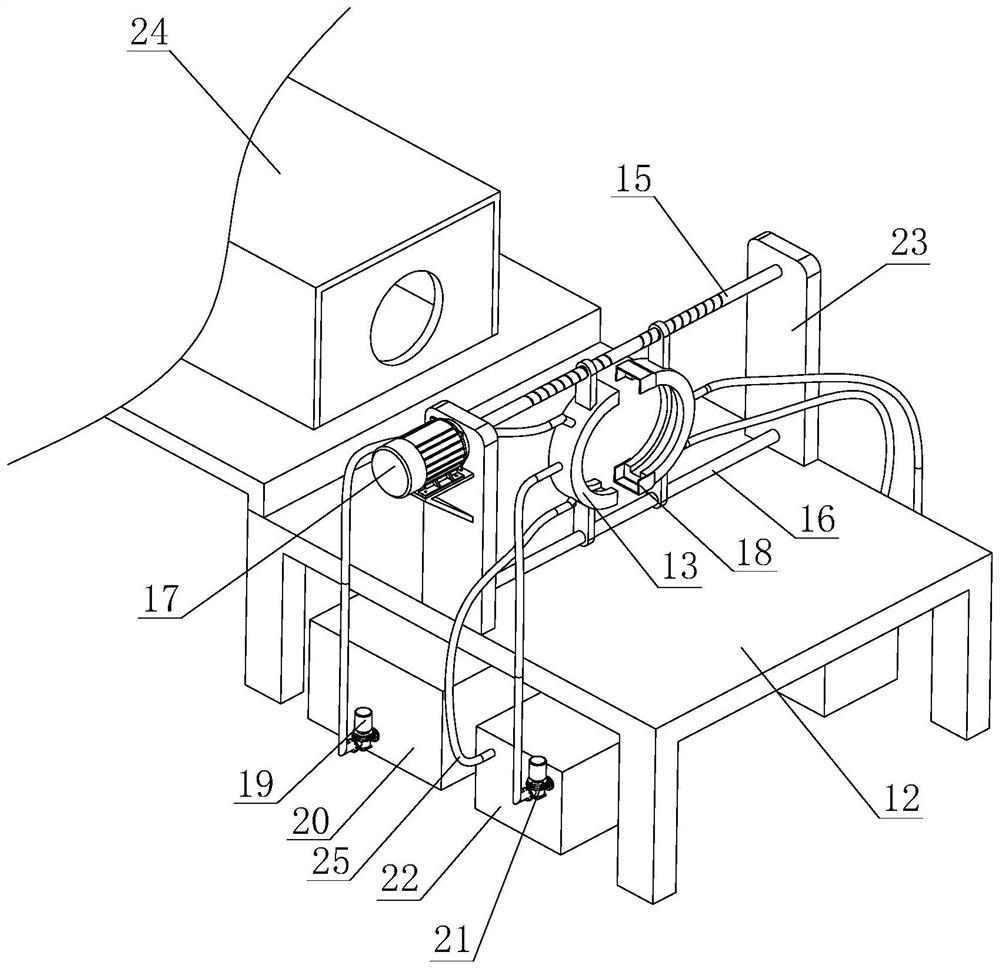

[0057] refer to image 3 and Figure 4 , Embodiment 2 of the present application discloses a cable processing system, including a production line 24, which is used for processing and forming cables, and the production line 24 drives the cables to travel intermittently, and the related technologies of cable production will not be repeated here. The production line 24 is provided with a welding ring machine, which is used for processing the cables as described in the first embodiment. After the cable is processed by the production line 24, the wear-resistant ring 8 is fixedly installed on the outside of the cable by a ring welding machine.

[0058] refer to image 3 and Figure 4 , The ring welding machine includes: a body 12 and two shaping dies 13 . The cable passes through the upper side of the body 12, and two shaping dies 13 are respectively located on opposite sides of the cable. The cross-sections of the two shaping dies 13 are arranged in a semicircular shape, the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com