Piston reciprocating magnetic repulsion generating (electric) module and its combined application system

A technology of electric and piston rings, applied in the direction of electric components, electrical components, electromechanical devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

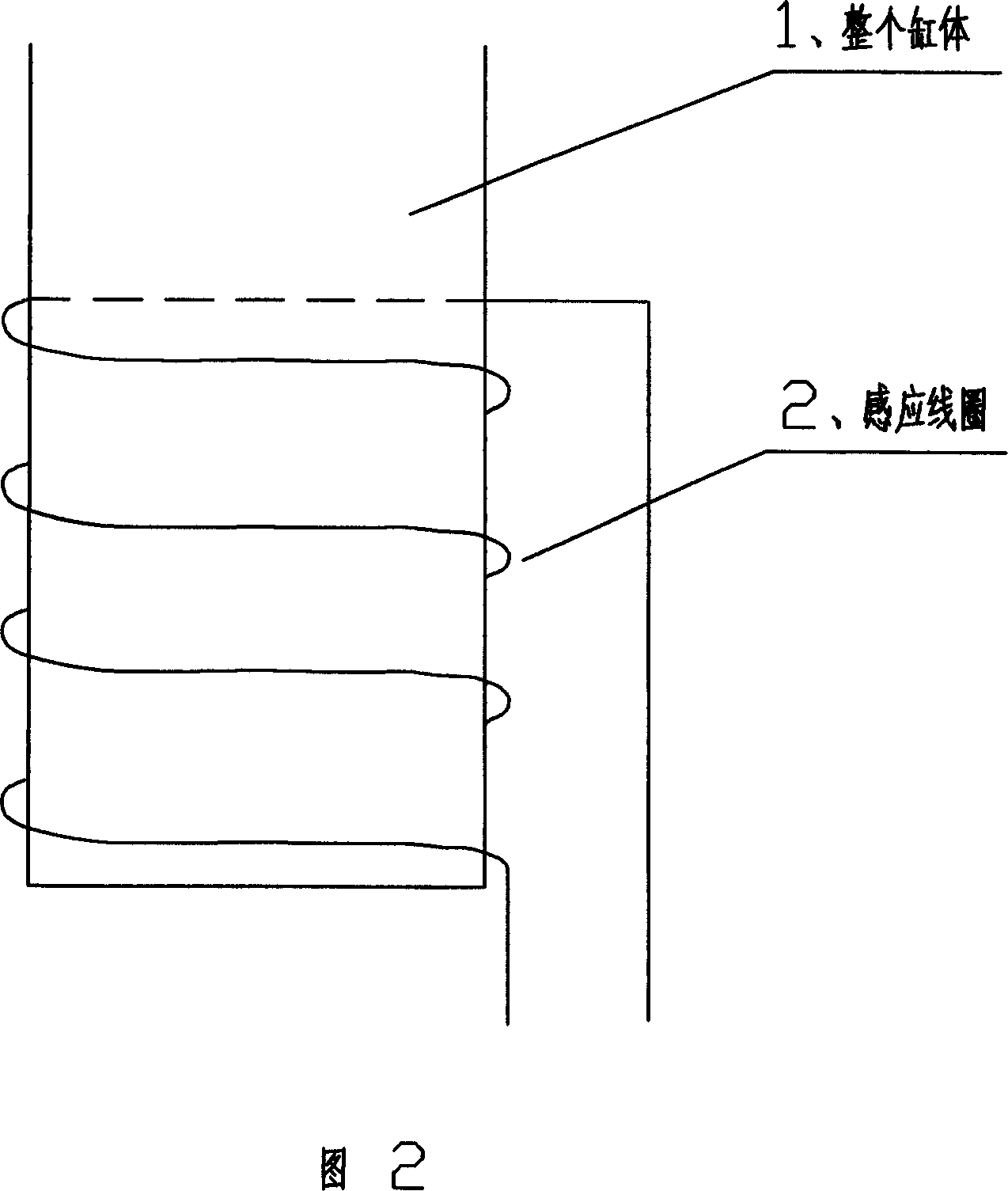

[0018] When the cylinder 1 moves back and forth under force, a current is generated in the coil 2.

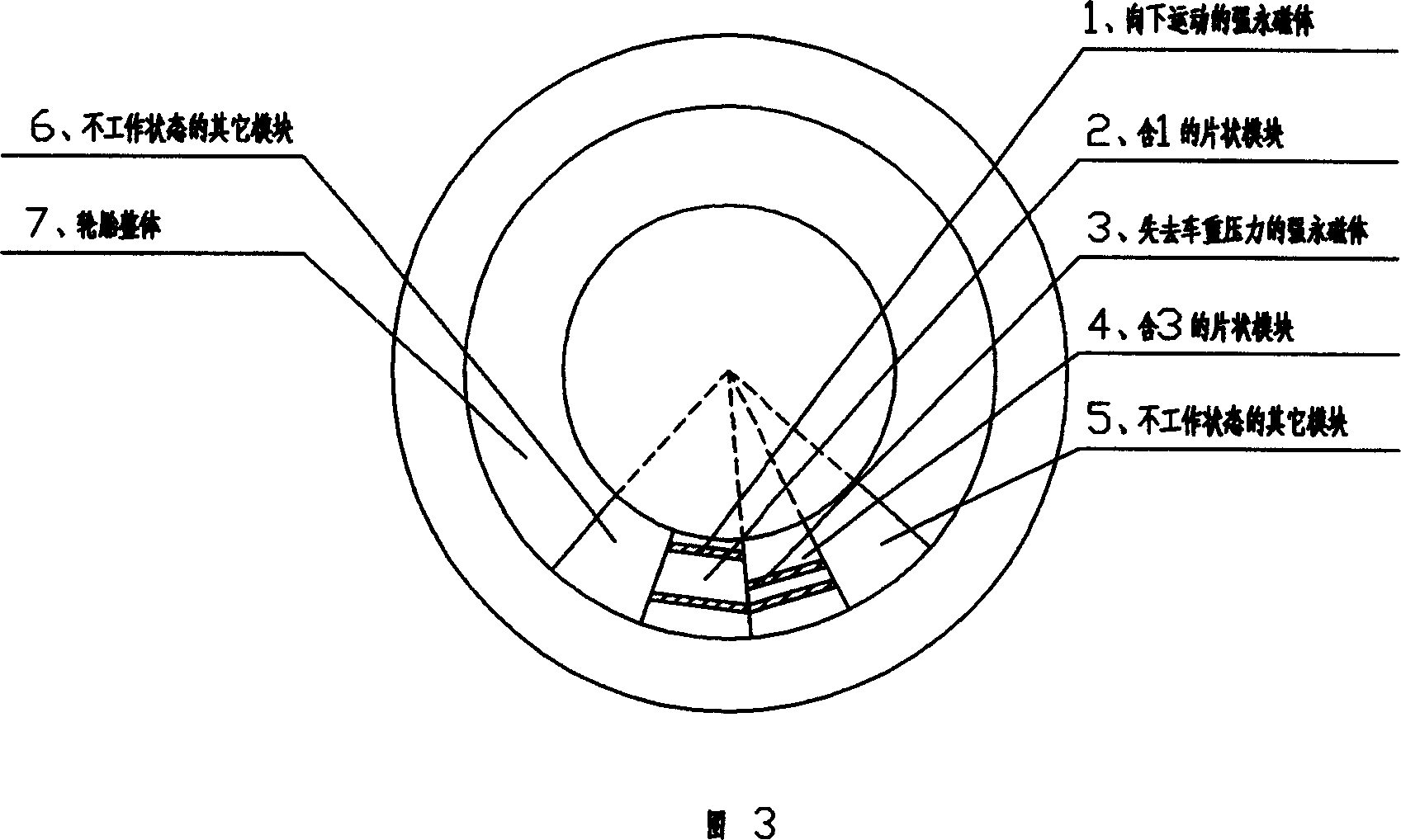

[0019] In Figure 3, 1 is the strong permanent magnet at the lower part of the pressure transmission rod that is moved downward by the pressure of the vehicle weight, 2 is the entire sheet module including 1, and 3 is the strong permanent magnet at the lower part of the pressure transmission rod that has just lost the pressure of the vehicle weight , 4 is the whole sheet module including 3, 5 is other modules in non-working state, 6 is other modules in non-working state, and 7 is the whole tire.

detailed description

[0020] When 7 tires rotate to the position shown in Figure 3, 1 receives the vehicle weight pressure downwards, and the coil outside the cylinder generates an induced current, and 3 loses the vehicle weight pressure, and the coil outside the cylinder generates an induced current, 2, 4, 5, 6, etc. Form a ring embedded system.

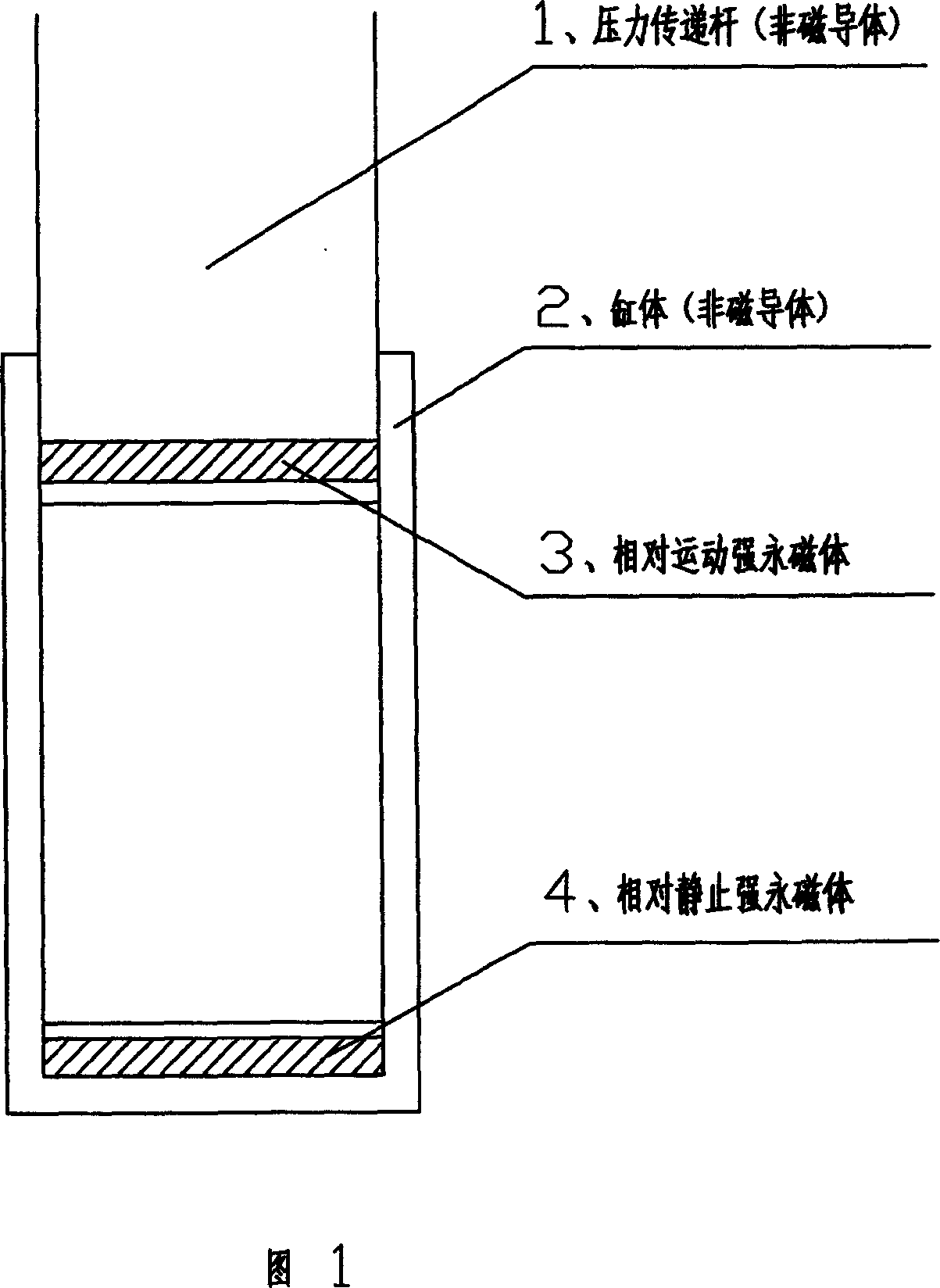

[0021] In Fig. 4, 1 is a strong per...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap