Wire, detector having wire, and die for wire

一种金属模、电缆的技术,应用在金属模领域,能够解决难以壳体、壳体形状限制、设计旋转传感器形状等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

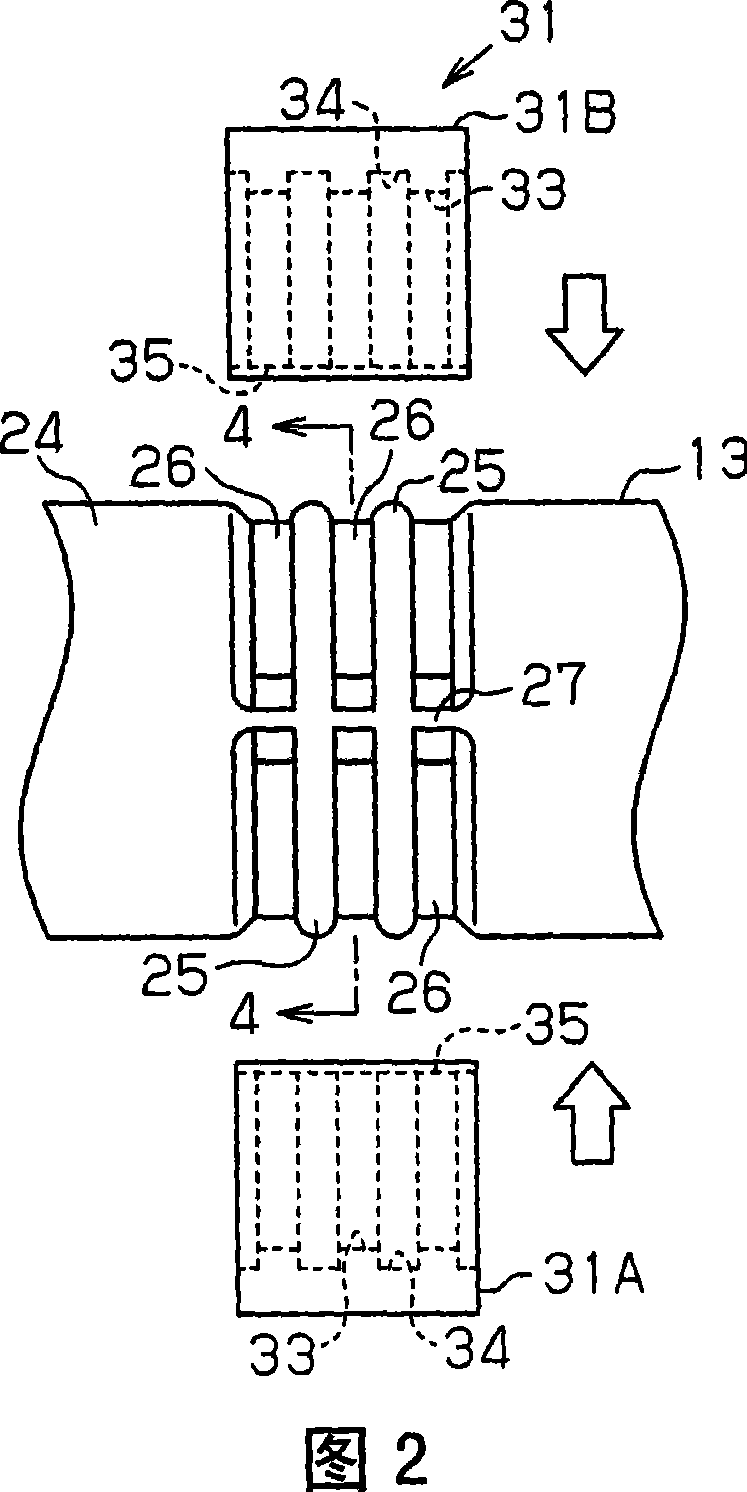

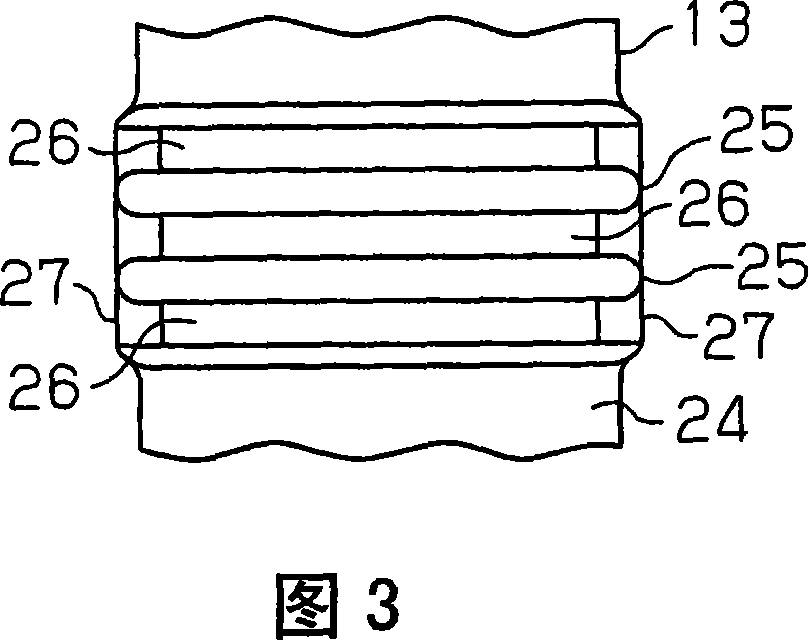

[0033] Hereinafter, an embodiment in which the present invention is embodied will be described based on FIGS. 1 to 10 . In this embodiment, the present invention is embodied as a rotation sensor 11 that detects the rotation speed of a wheel.

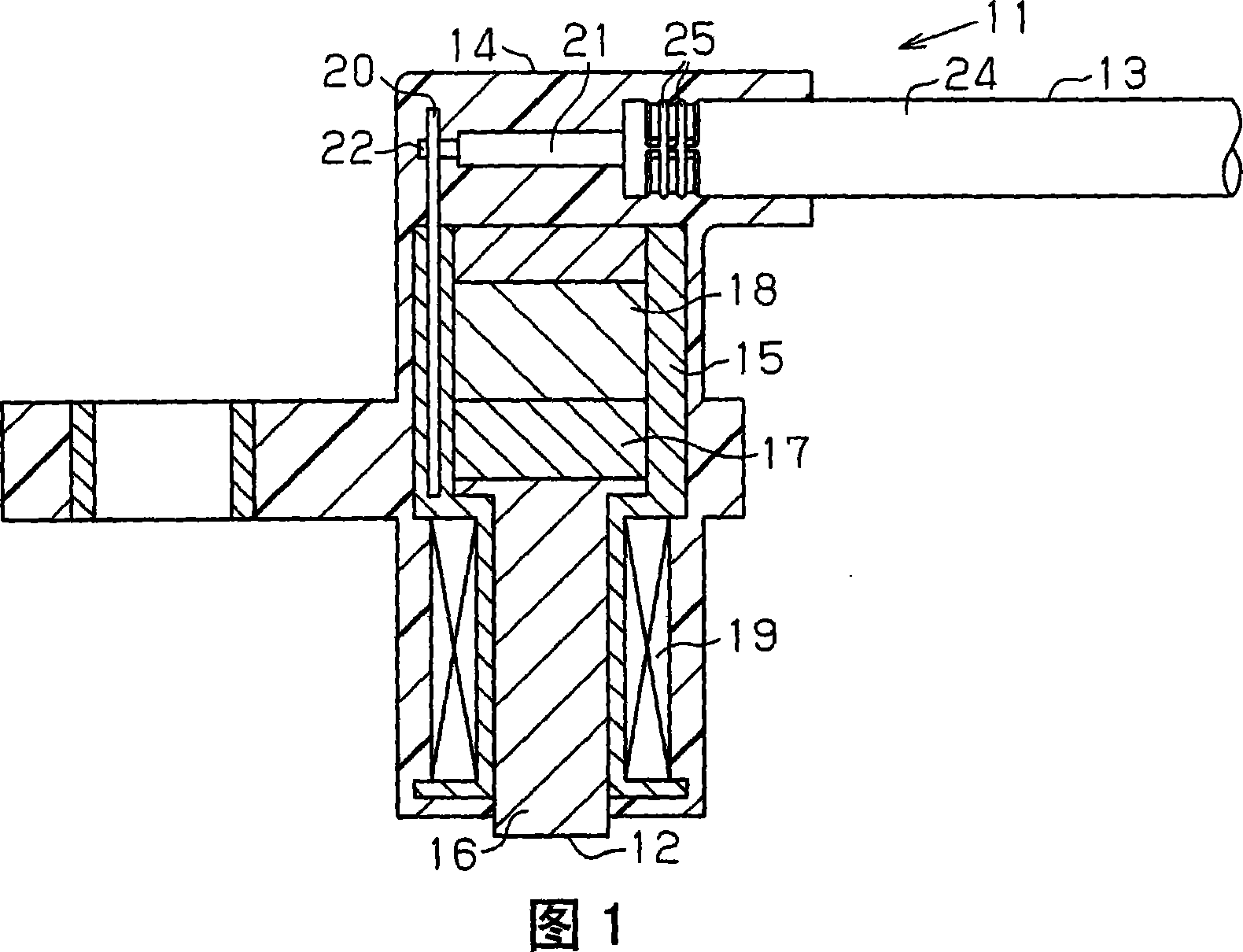

[0034] FIG. 1 roughly shows a side sectional view of a rotation sensor 11 as a detector. The rotation sensor 11 adopts an electromagnetic pickup method, and is disposed opposite to a rotor (not shown) separately disposed on the vehicle. The rotation sensor 11 includes: a sensor unit 12 ; a cable 13 connected to the sensor unit 12 ; and a case 14 covering the sensor unit 12 and the cable 13 (in detail, including the end of the cable 13 connected to the sensor unit 12 ).

[0035] The sensor unit 12 includes a hollow cylindrical bobbin 15 formed of a resin material. Inside the bobbin 15, a yoke 16, a magnet 17, and a back core 18 are provided. The yoke 16, the magnet 17, and the back core 18 are formed of a magnetic material and constitu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com