Mechanical pin

A technology of machinery and refills, applied in mechanical pencils, printing, writing utensils, etc., can solve problems such as deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

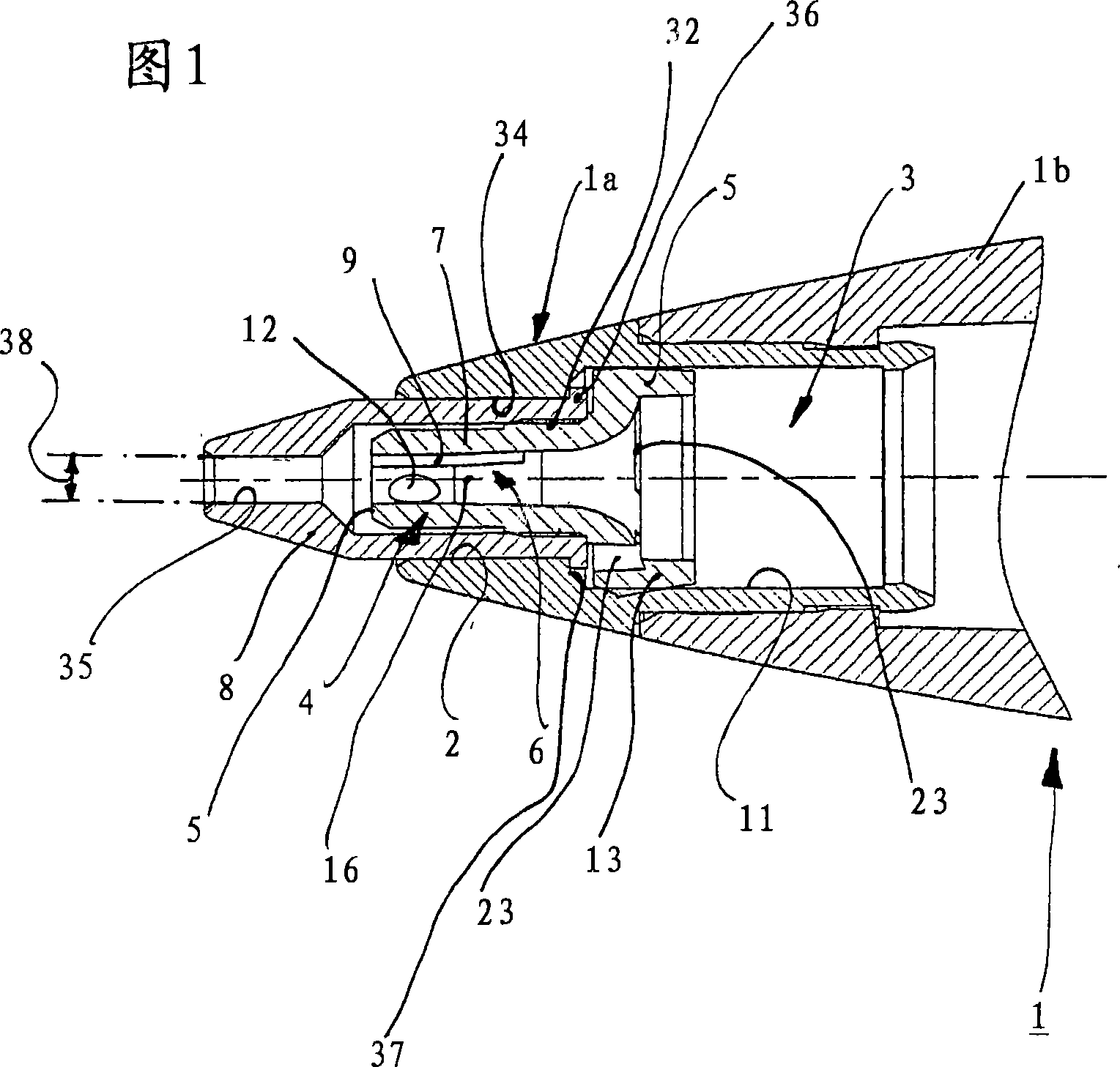

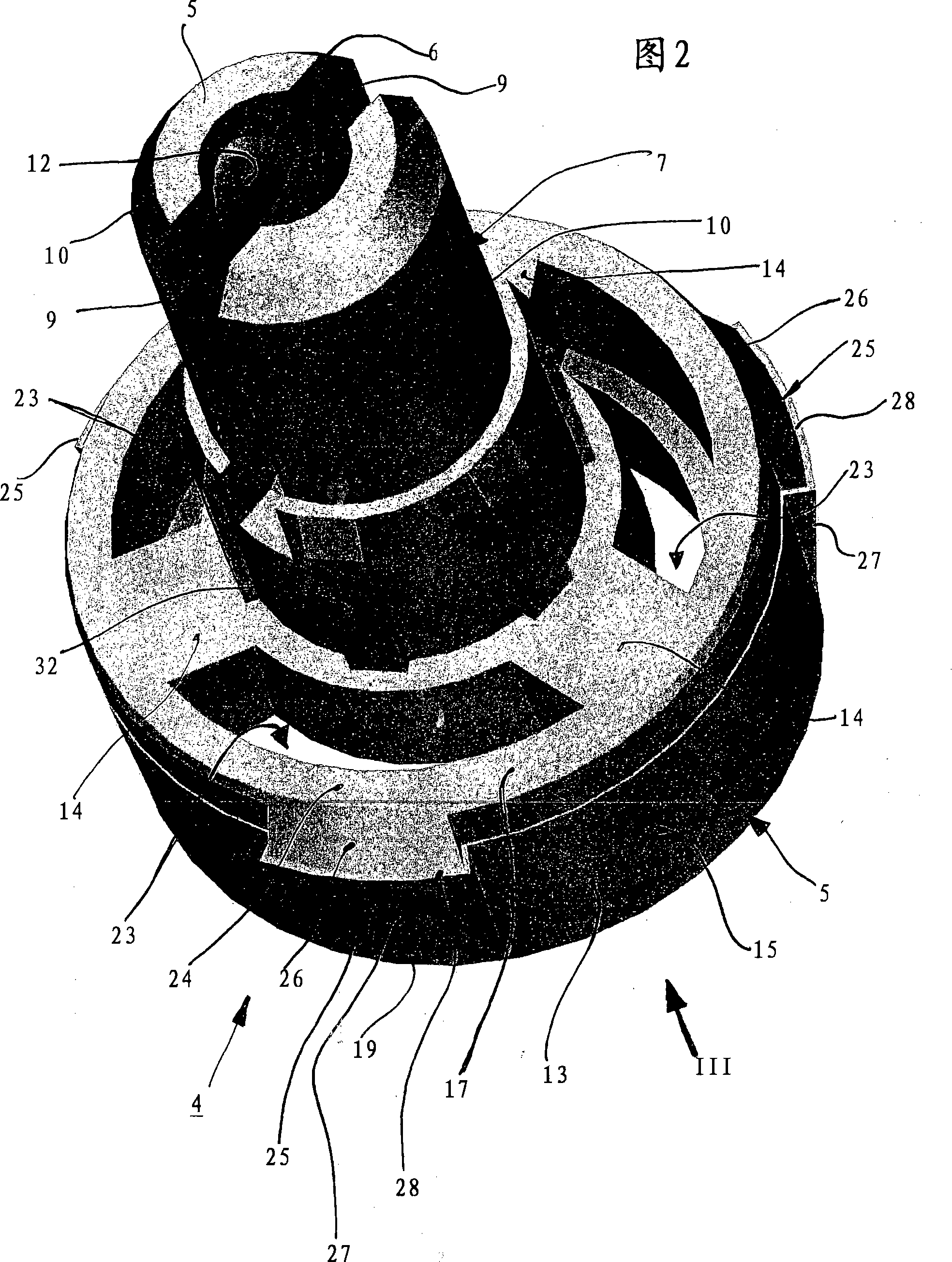

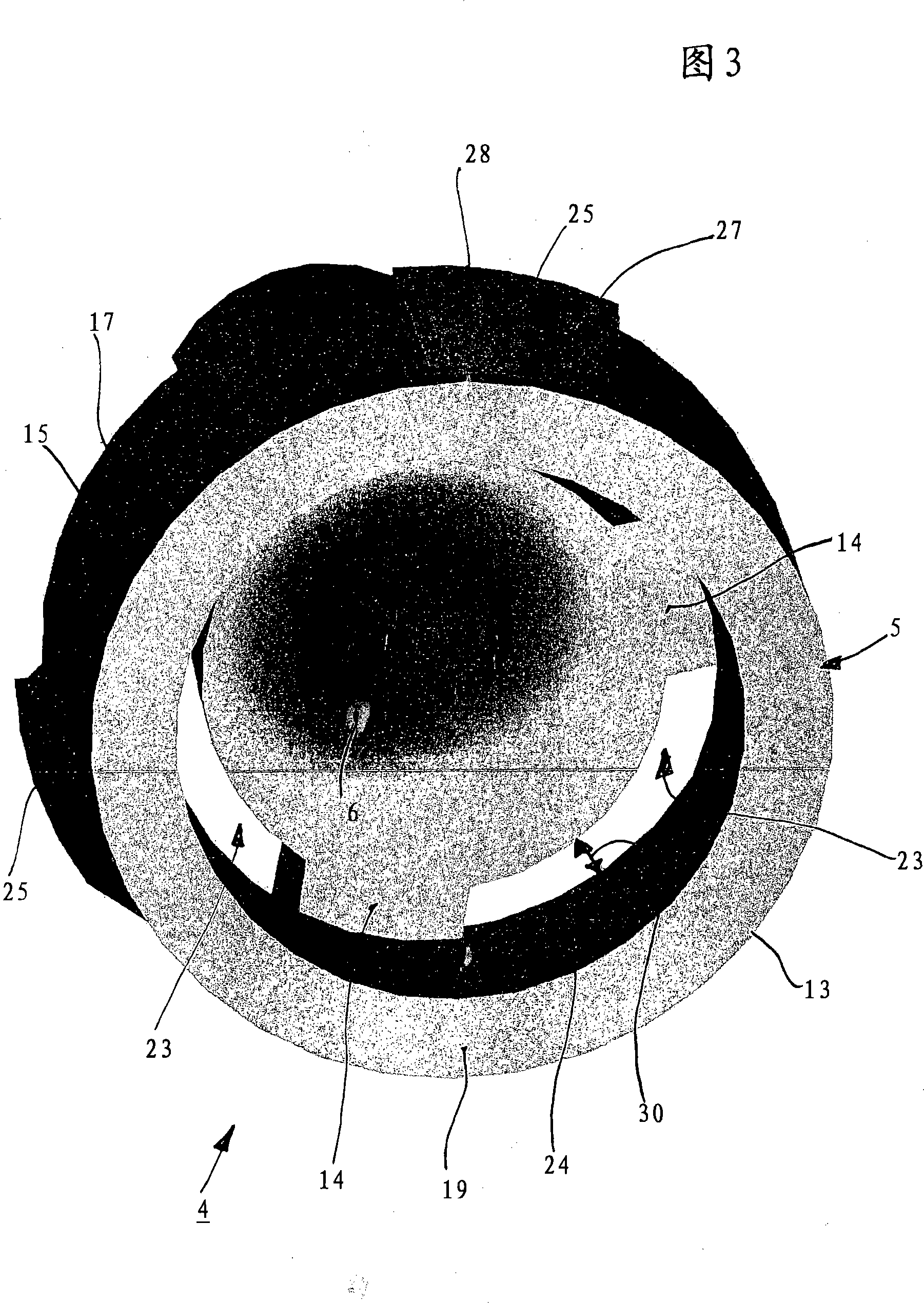

[0020] As can be seen in FIG. 1, a pen 1 of the present invention includes a shaft 1b having a tip 1a at its front end. A sliding region 3 is present in the tip 1a. Arranged axially displaceably therein is a lead stopper 4 designed as a one-piece plastic injection-molded part. The lead stopper 4 comprises a substantially cylindrical clamping body 7 through which a hole 6 extending concentrically to its central longitudinal axis or the central longitudinal axis 16 of the lead stopper passes and on which the lead capillary tube is fitted. 8. Starting from the front face 5 of the clamping body 7, two diametrically opposite axial grooves 9 are formed therein. In this way, two diametrically opposite clamping tongues 10 are formed, which are each provided with a radially inwardly protruding projection 12 on their inner faces. If the refill is fed through the hole 6 by means of the advancing mechanism of the pen 1, it passes through the protrusion 12, thus radially expanding the c...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap