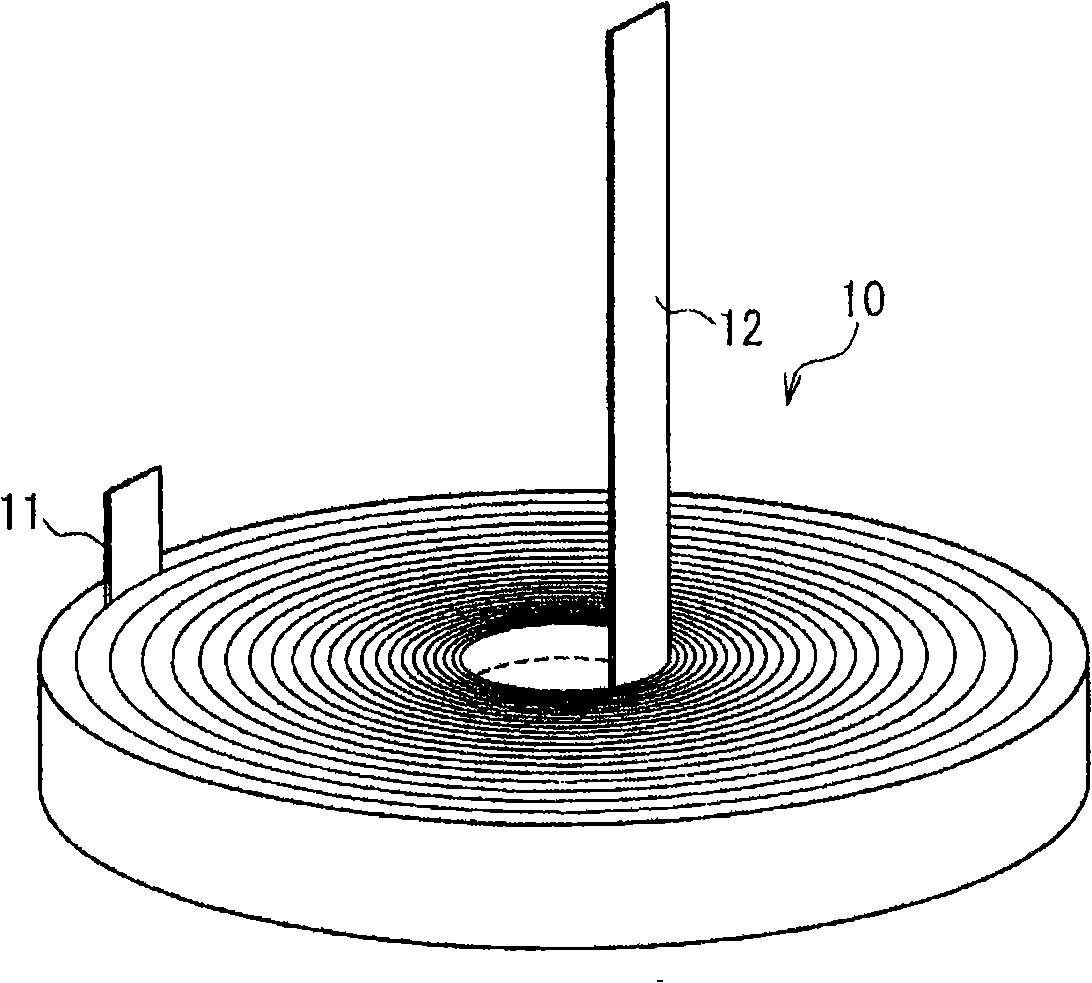

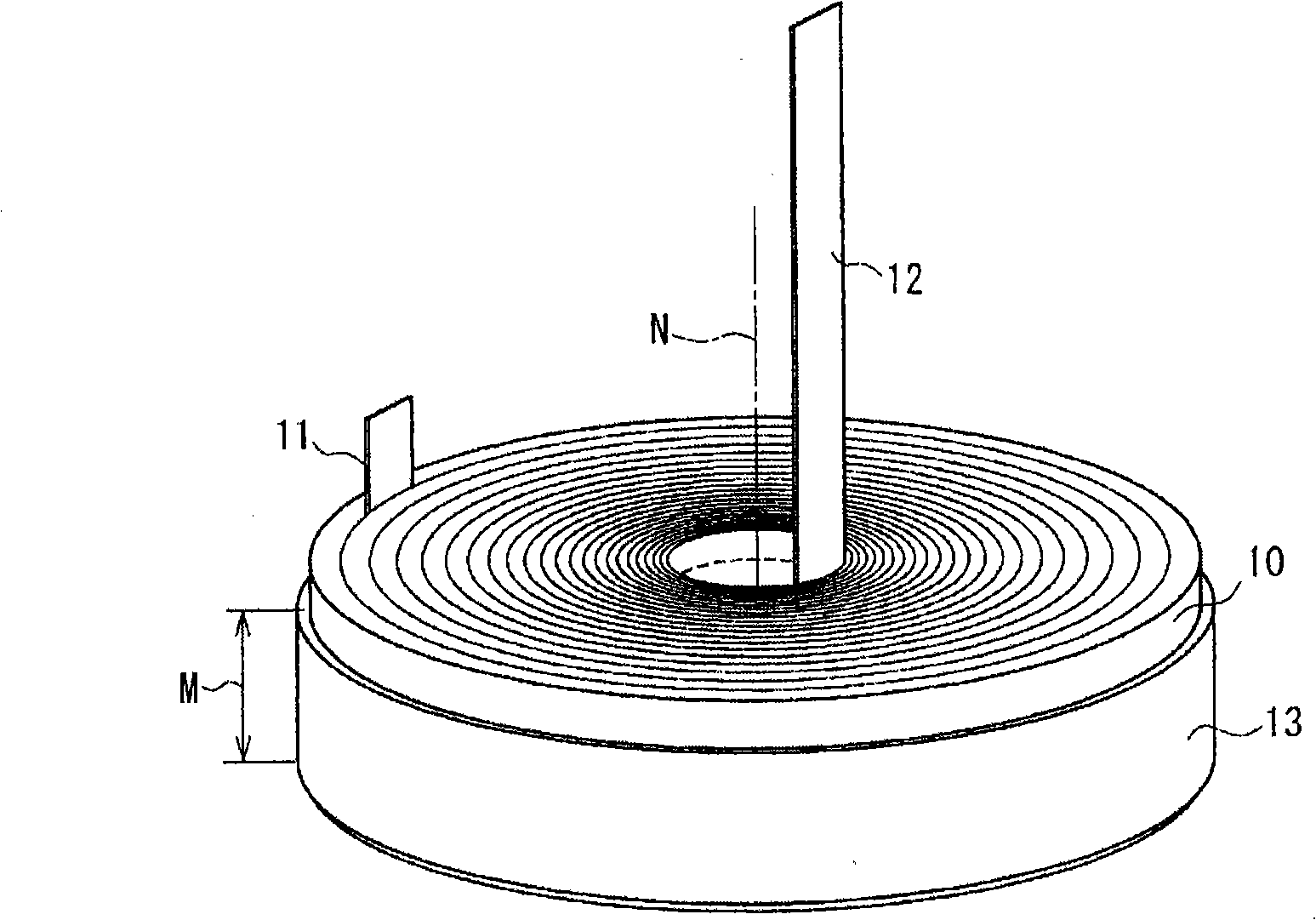

Nummular non-aqueous electrolyte secondary battery

A non-aqueous electrolyte and secondary battery technology, applied in the direction of secondary batteries, secondary battery manufacturing, cylindrical shell batteries/batteries, etc., can solve the problems of reduced discharge load characteristics, thick electrodes, low output applications, etc., to achieve The effect of high discharge load characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

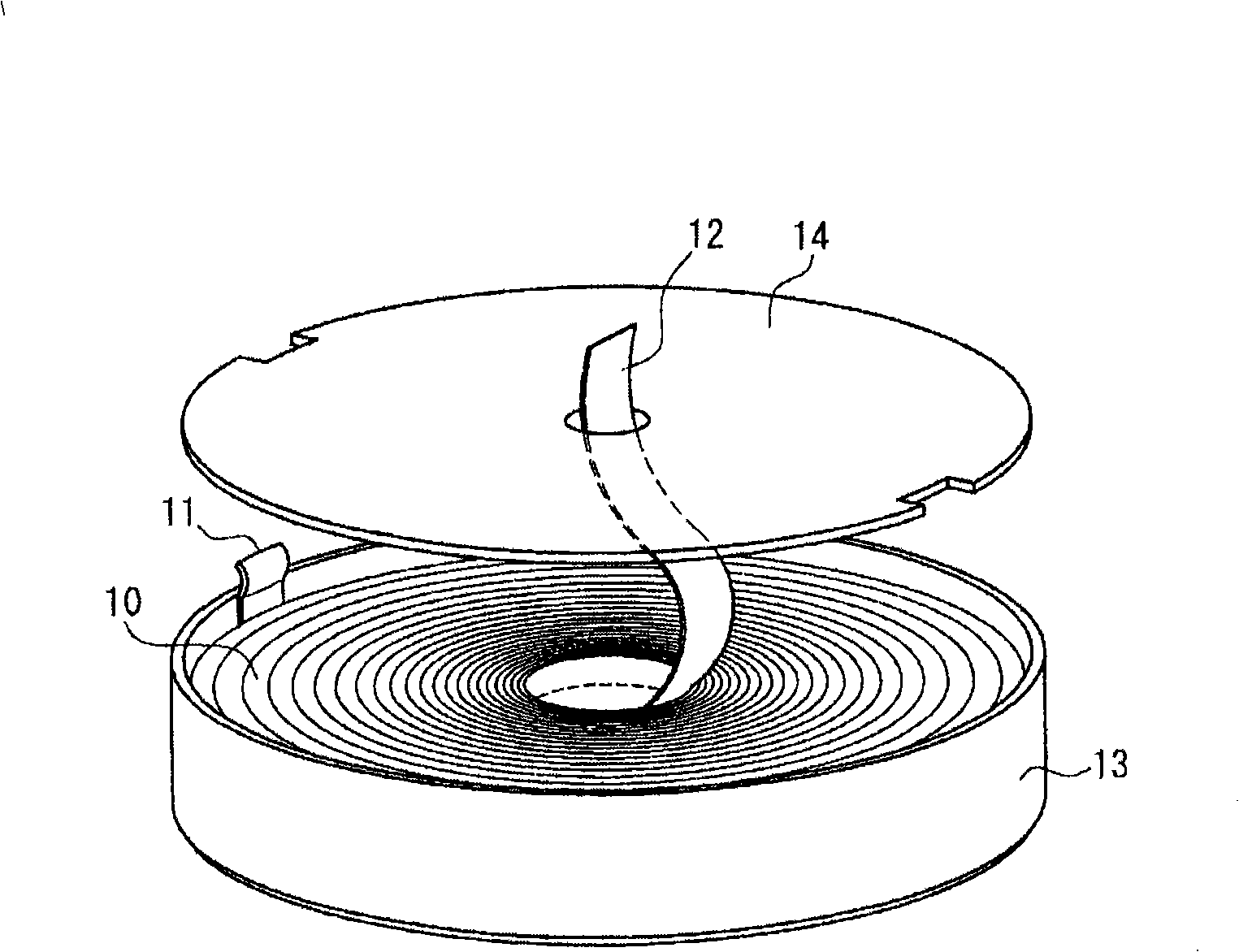

Embodiment 1

[0078]

[0079] Using N-methyl-2-pyrrolidone (NMP N-methyl-2-pyrrolidone) as a solvent, add 80 parts by weight of LiCoO as a positive electrode active material 2 , 10 parts by weight of acetylene black (acetylene black) as a conductive additive and 5 parts by weight of polyvinylidene fluoride (PVDF polyvinylidene fluoride) as a binder, and mixed uniformly to prepare a paste containing a positive electrode mixture. The paste containing the positive electrode mixture was coated on both sides of an aluminum foil with a thickness of 20 μm as a positive electrode current collector so that the active material coating length on the surface side was 1221 mm and the active material coating length on the back side was 1155 mm, and dried. . Then, a calendar treatment was performed to adjust the thickness of the electrode so that the total thickness was 134 μm, and it was cut into a width of 3.0 mm to form a strip-shaped positive electrode. Uncoated active material portions were formed...

Embodiment 2

[0092]

[0093] The thickness of the positive electrode current collector is 25 μm, the coating length of the active material is 678 mm on the surface side, 624 mm on the back side, and the total thickness after calendering is 162 μm, and the width is 2.0 mm. The same as in Example 1 except that Operate and make the positive electrode.

[0094]

[0095] The thickness of the negative electrode current collector is 20 μm, the coating length of the active material is 2, the surface side: 667 mm, the back side: 667 mm, the total thickness after calendering is 177 μm, and the width is 2.5 mm, except that it is the same as Example 1 Operation, make the negative electrode.

[0096] Using the above-mentioned positive electrode and the above-mentioned negative electrode, the thickness of the separator is 3.3mm, and the battery can with an outer diameter of 20mm and a height of 4.0mm is used, except that the same operation is performed as in Example 1, and the volume of the battery ...

Embodiment 3

[0099]

[0100] The coating length of the active material was 3146 mm on the front side, 3047 mm on the back side, and the total thickness after calendering was 115 μm and the width was 3.5 mm. The positive electrode was produced in the same manner as in Example 1.

[0101]

[0102] The coating length of the active material is: 3121 mm on the front side and 3121 mm on the back side, the total thickness after calendering is 122 μm, and the width is 4.0 mm. The negative electrode is produced in the same manner as in Example 1 except that.

[0103] Using the above-mentioned positive electrode and the above-mentioned negative electrode, the width of the separator is 4.8mm, and the battery can with an outer diameter of 35mm and a height of 5.5mm is used, except that the same operation is performed as in Example 1, and the volume of the battery is 5.3cm. 3 coin-shaped non-aqueous electrolyte secondary battery.

[0104] The outer diameter D of the wound body in this embodiment is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap