Magnetic particle for separation as well as preparation method and application thereof

A magnetic particle and magnetic core technology, which is applied in the fields of magnetism of inorganic materials, analytical materials, dyeing polymer organic compounds, etc., can solve the problems of target protein degradation, cell damage, slow separation speed, and low labor efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

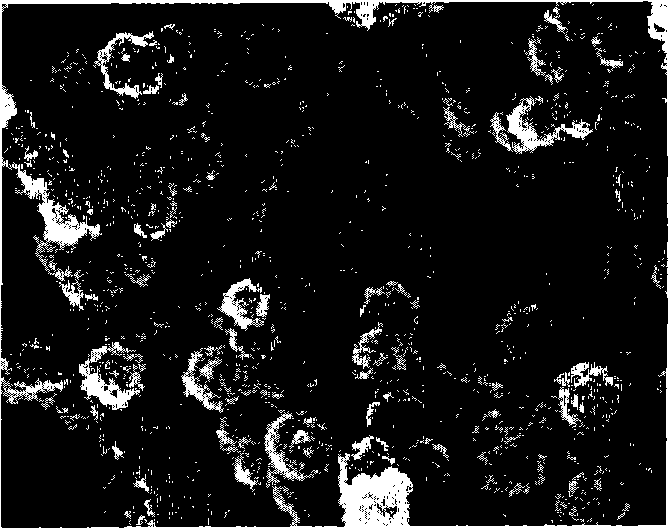

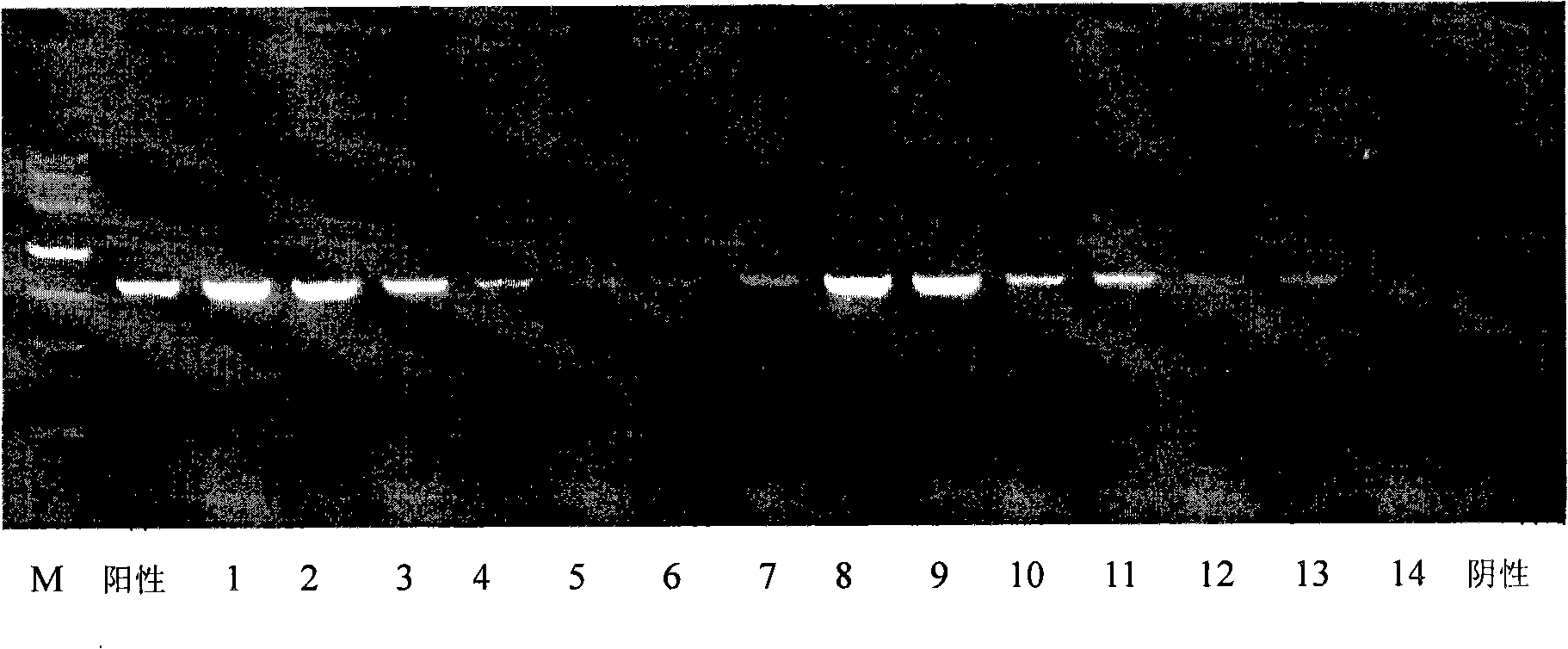

Method used

Image

Examples

Embodiment 1

[0039] Embodiment 1, the preparation of the magnetic particle of the present invention

[0040] Prepare Fe with a molar ratio of 1:1:0.3 2 o 3 : Fe 3 o 4 :TiO 2 Aqueous iron solution. In the presence of 1.5M ammonium hydroxide or sodium hydroxide, the aqueous iron solution was mixed to form a superparamagnetic iron oxide precipitate. The precipitate (ie colloid) was washed with water to pH 7.2 and then washed again in NaCl to maintain the fineness of the iron oxide crystals. Finally, the prepared colloids were stored in deionized water. Subsequently, 25 ml of the colloidal slurry was incubated with 50% by volume of perchloric acid to colloidize the entire magnetic core by a magnetic field. No matter how many times a magnetic field is applied to the particle, the particle does not become permanently magnetized. A 10% benzyl peroxide solution was added to 40 ml of colloid and incubated at 65° C. for 24 hours, followed by washing with deionized water. The magnetic part...

Embodiment 2

[0041] Example 2, preparation of magnetic particles of the present invention coated with ethylene oxide layer and dextran

[0042] For the ethylene oxide coating, 1 g of the magnetic core prepared in Example 1 was mixed with 8 ml of allyl glycidyl ether, 3 ml of divinylbenzene and 0.1 g of K 2 S 2 o 8 Incubate at 50°C for 3 hours, then wash with H 2 O washing.

[0043] For dextran coating, the magnetic particles were resuspended in β-divinylbenzene to a concentration of 20% and shaken continuously at 65°C for 24 hours. After equilibrating the pressure to atmospheric pressure, the solution was sonicated with an ordinary water-bath sonicator at an output of 75% for 2 minutes, and then washed with water several times. The supernatant was discarded, and the magnetic particle pellet was incubated with 12% dextran solution at 42°C for 16 hours. The magnetic particles were washed with water several times, and the prepared dextran-coated magnetic particles were stored in water ...

Embodiment 3

[0045] Example 3. Preparation of magnetic particles of the present invention containing oxidized dextran

[0046] With the magnetic particle prepared in 50g embodiment 2 and 0.01M NaIO 4 Incubate for 10 minutes. 50 g of the prepared oxidized dextran magnetic particles were washed with PBS (phosphate buffered saline), and resuspended in 100 ml of PBS.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap