Selector fork for a change-speed gearbox

A technology for shifting forks and gearboxes, which is applied in the field of shifting forks, can solve the problems of difficulty in welding and cannot be realized, and achieve the effects of improving economy, reducing the weight of shifting forks, and connecting them firmly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

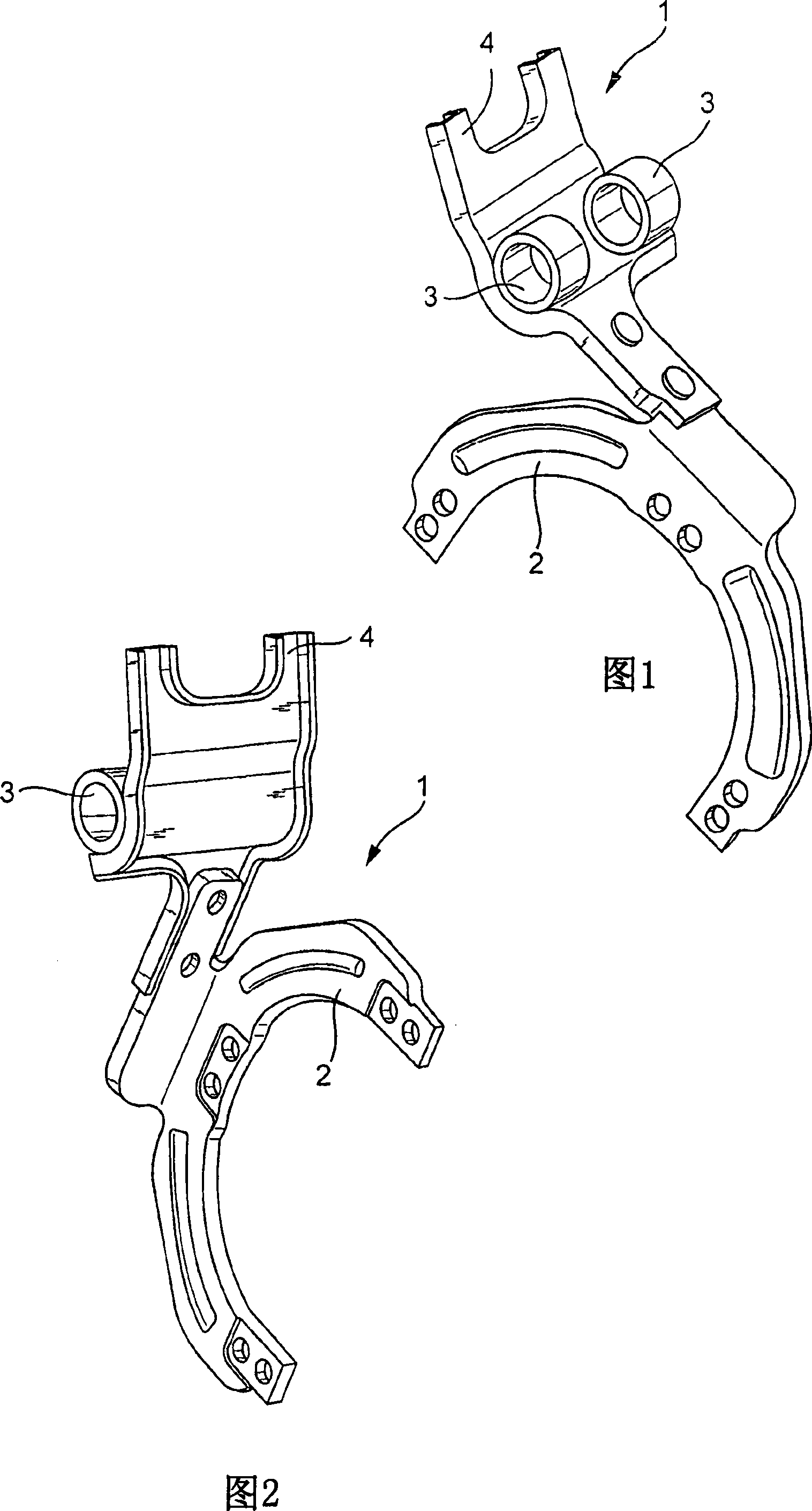

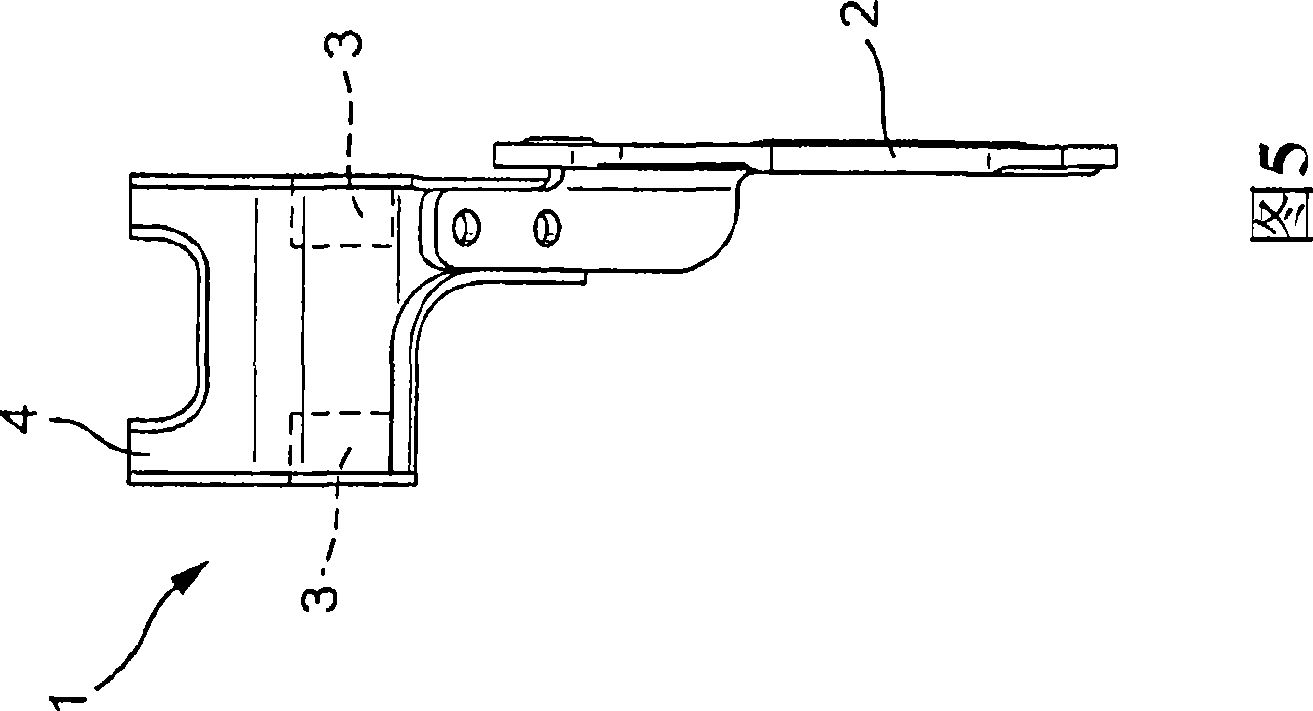

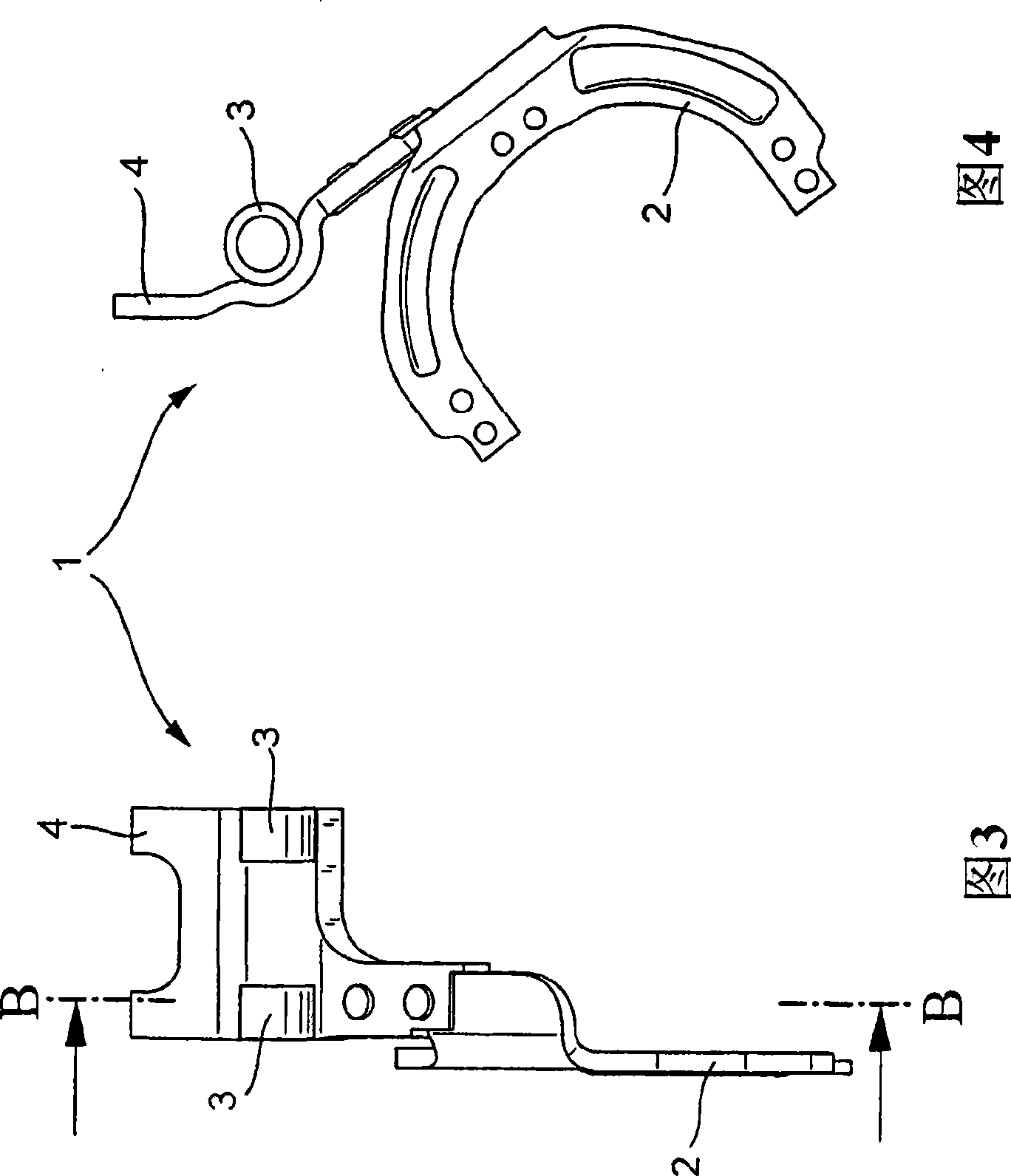

[0028] FIG. 1 shows a shift fork 1 for a gearbox. The shift fork 1 is made up of three parts which are independently made and connected together. Among them, firstly a fork-shaped base body 2, then a support element 3, and finally a transmission element 4, which interacts with a not shown operating mechanism, which pushes the shift fork in translation to a position also not shown. on the axis. Wherein the fork-shaped base body 2 clamps the gear in the gear box and pushes it along the axial direction.

[0029] The support 3 is currently formed by two sleeves (see especially FIG. 2 ), which are aligned with each other and allow the passage of a support shaft, not shown.

[0030] All three said parts 2 , 3 , 4 are made of sheet metal, that is to say they are fabricated from sheet metal. Thickness of metal plate d 1 、d 2 (See Image 6 ) is chosen such that it exhibits the best stiffness for a particular member stress. In principle it is also possible to choose a different th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com