Washing machine with sealing assembly for bearing assembly of washing machine lye container

A technology of lye container and bearing assembly, which is applied in the field of washing machines with sealing assemblies for the lye container bearing assembly of the washing machine, which can solve the problems of difficult removal of the lye container and the cost of injection molding tools, etc., and achieve the effect of improving the sealing function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

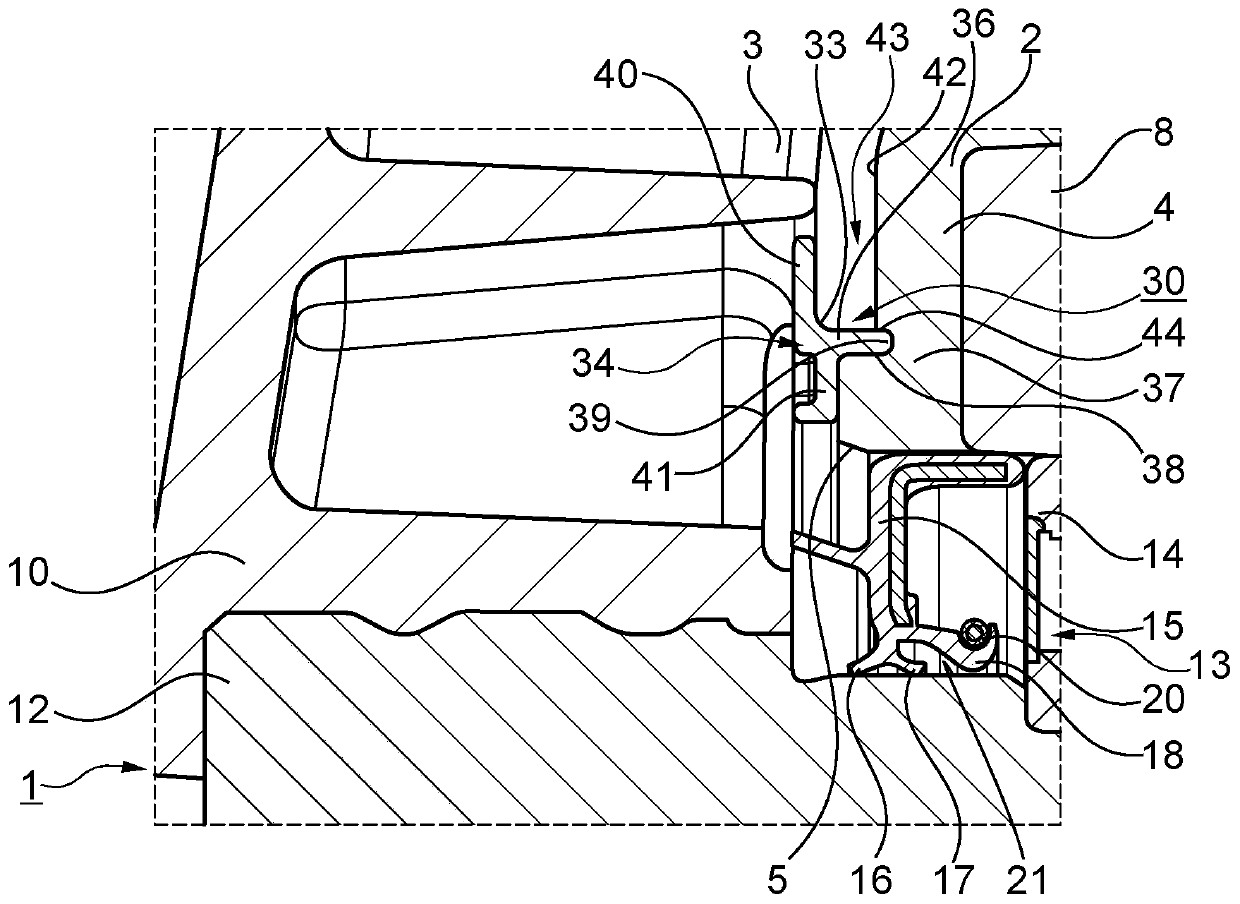

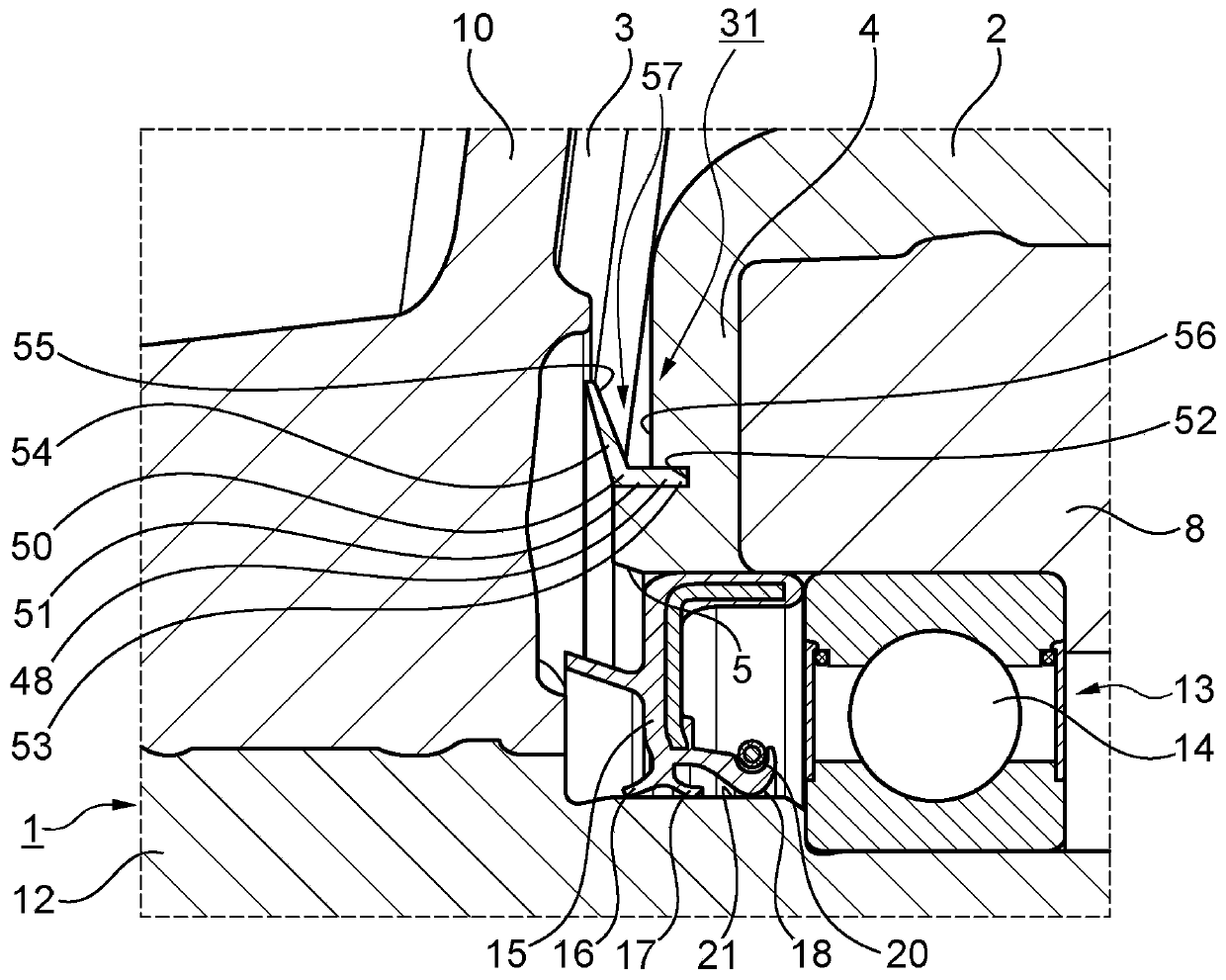

[0018] exist figure 1 and figure 2 The washing machine 1 shown only partially in each has a substantially cylindrical lye container 2 in which a substantially cylindrical laundry drum 3 is mounted rotatably about a horizontal axis of rotation, In this regard, reference can be made to the analogous fragment shown in the drawing in EP 1 514 966 B1 in this respect. The lye container 2 is produced from an lye-resistant plastic and includes a bottom 4 which forms its rear end (in conventional front-loading washing machines) of the lye container 2 . The bottom 4 has an opening 5 behind which a bearing housing 8 is arranged in the axial direction away from the lye container in a known manner, for example as mentioned in the opening paragraph. Related content of EP1514966B1. The bearing housing 8 is carried by a bearing intersection, not shown, which is connected to the lye container 2 (or to the bottom 4 ). The laundry drum 3 has a flange 10 which is connected in a rotationally ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com