Drop tester bench

A drop test and air gripper technology is applied in the field of test machines for short-distance drop experiments, which can solve the problems of high labor intensity and inconvenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

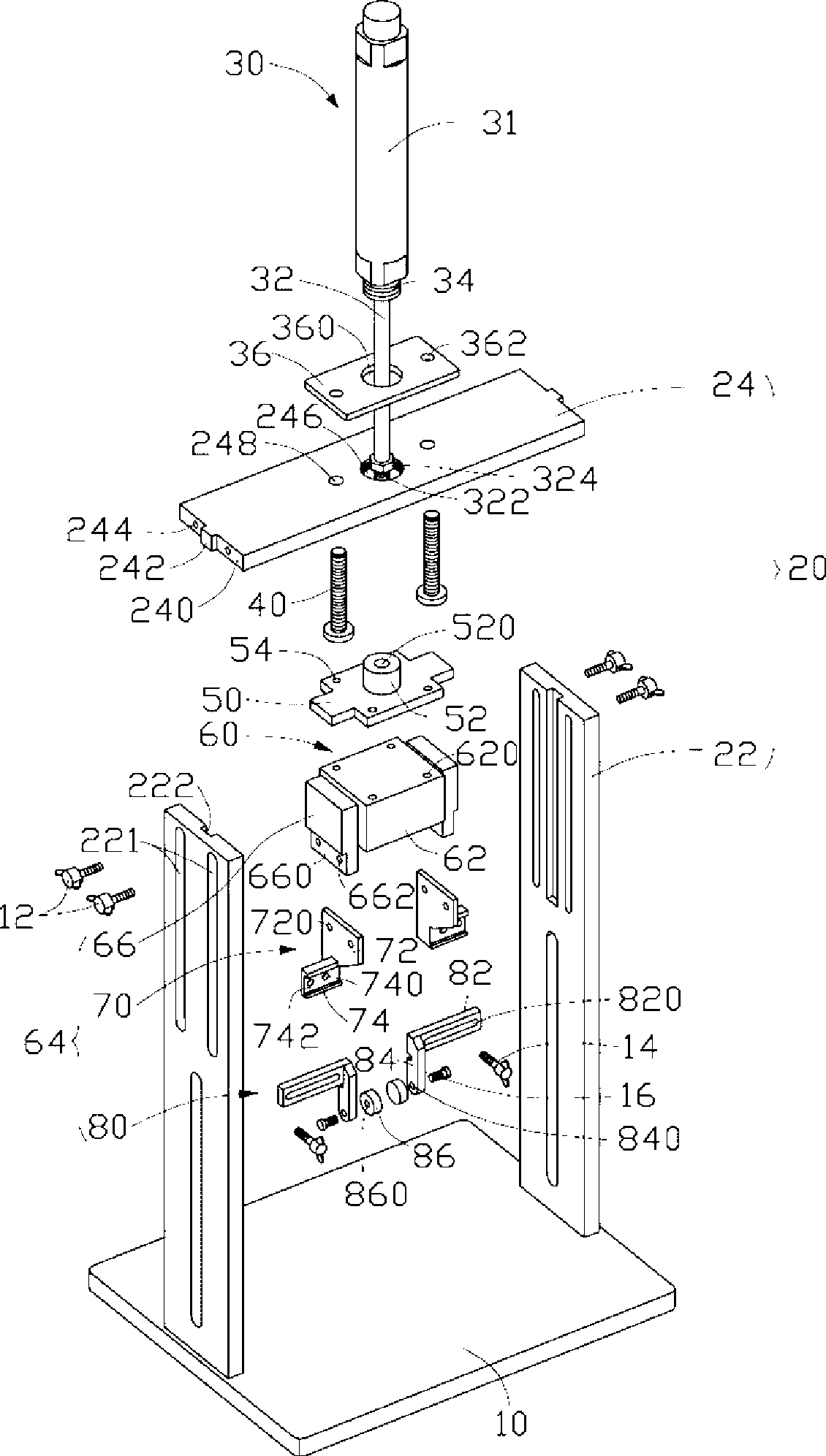

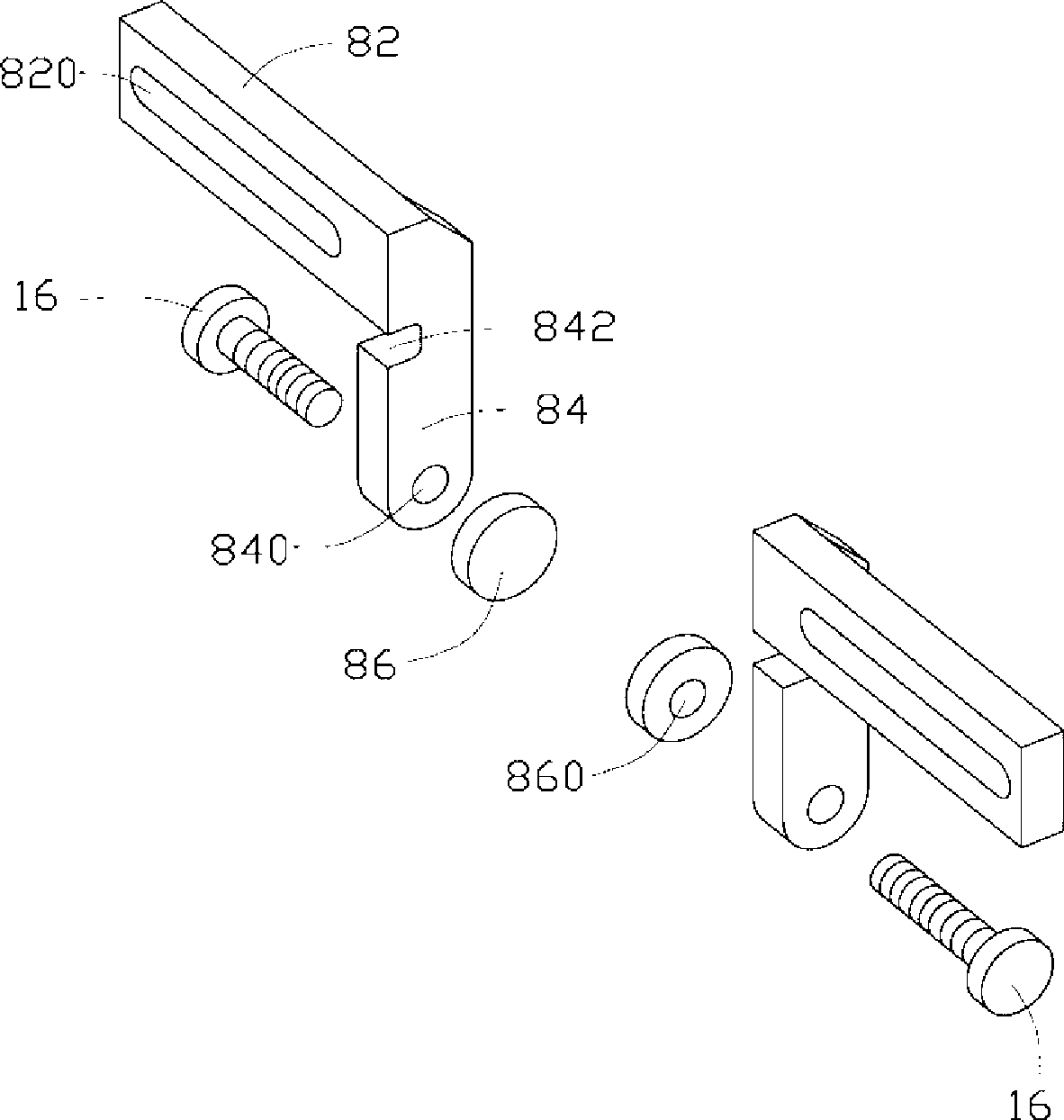

[0012] Please refer to figure 1 , the preferred embodiment of the drop test machine of the present invention is used in the product drop test to test the workpiece 100 (see Figure 5 ) repeatedly picked up and dropped. The drop test machine includes a base 10, a bracket 20 installed on the base 10, a cylinder 30 installed on the bracket 20, a connecting piece 50 and an air gripper connected to the connecting piece 50 60.

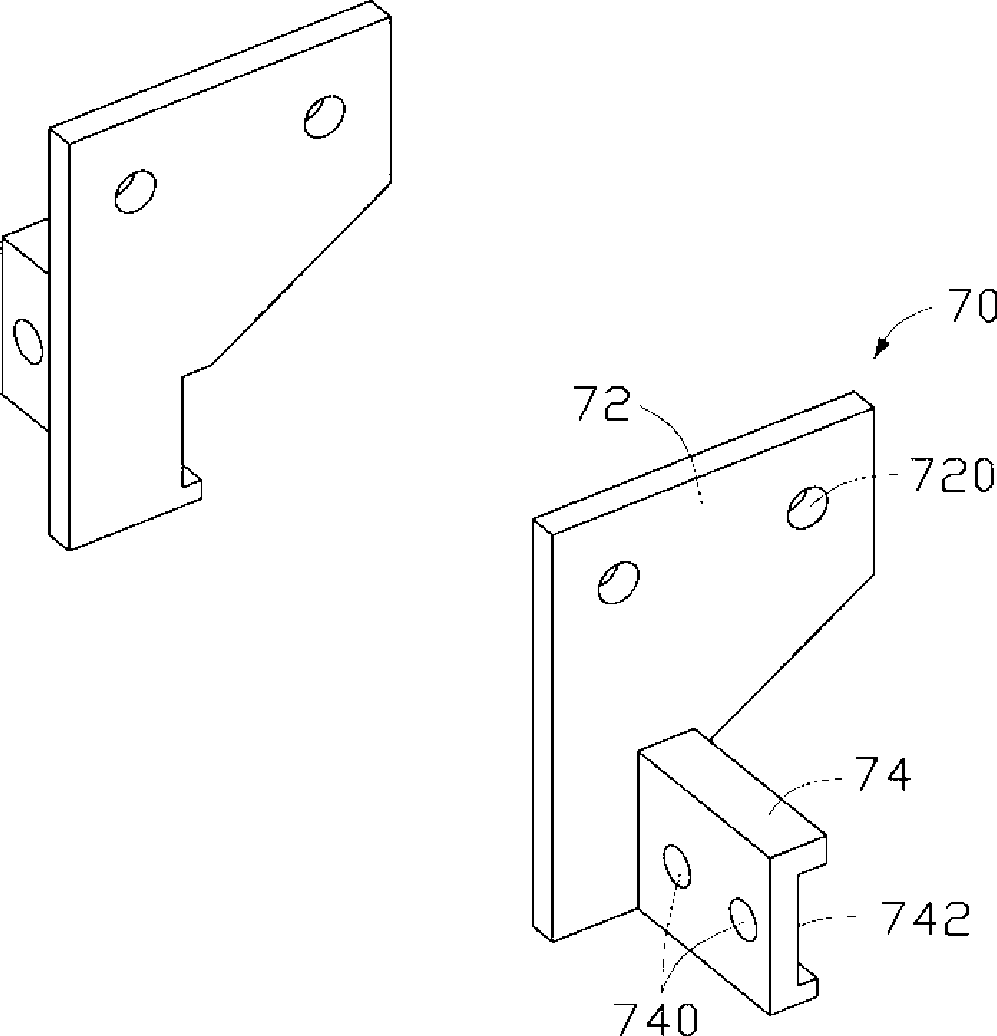

[0013] The bracket 20 is in an inverted "U" shape, and includes two support plates 22 vertically installed on the base 10 and an adjustment portion 24 connecting the two support plates 22 . Two long and narrow guide holes 221 and a limiting groove 222 are provided on the two supporting plates 22 , and the limiting groove 222 of each supporting plate 22 is located between the two guiding holes 221 . The adjustment part 24 is a rectangular plate, a larger screw hole 246 is opened in the middle part, and two smaller fixing holes 248 are opened on both sides ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com