Automatic powder feed circulating device of full-automatic glitter machine

A recycling device and glitter powder technology, which is applied in the direction of gold powder printing, printing machines, general parts of printing machinery, etc., can solve the problems of reducing production efficiency, unfavorable recovery of glitter powder, dust pollution and unfavorable environmental protection, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

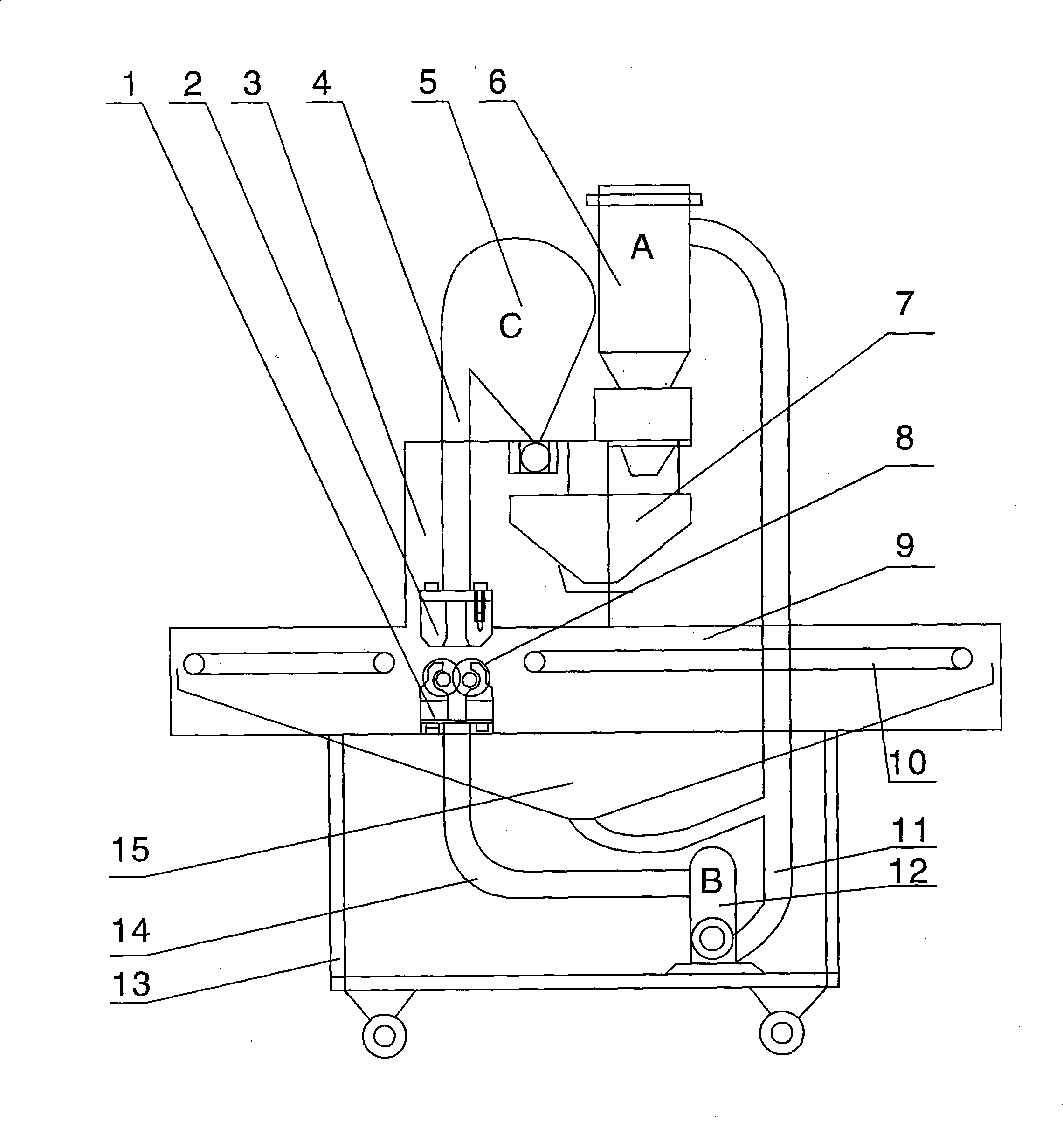

[0007] Below in conjunction with accompanying drawing, the present invention is described in further detail:

[0008] (1) Installation process: first install two lower frame crossbeams 9 in parallel on the top of the lower frame 3, the upper frame 3 is installed on the lower frame crossbeam 9, wind powder separator C 5 with powder suction machine, powder suction The air powder separator A 6 of the machine is installed above the upper frame 3, and the upper powder hopper 7 is suspended in the middle of the upper frame 3, and the air powder separator B 12 with the powder suction machine is arranged on the lower frame 13, and the upper powder suction The air duct 4 is connected to the upper powder suction port 2, the air powder separator C 5 with a powder suction machine is installed above the upper powder hopper 7, the lower powder suction port 1 is below the upper powder suction port 2, and the presser wheel shaft is used to The two ends of 8 are fixed on the lower frame crossb...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap