Piling machine

A pile rod and the other side technology is applied in the field of pile driver structure, which can solve the problems of large physical strength and slow speed of the operator, and achieve the effects of quick and convenient disassembly and installation, flexible and safe use, and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

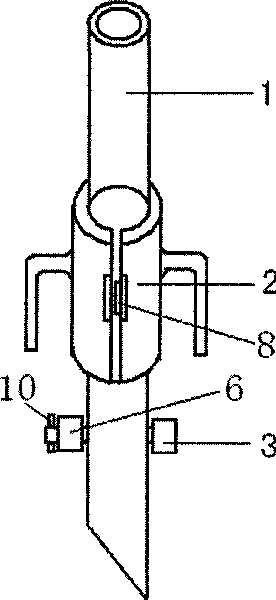

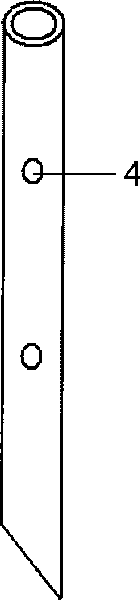

[0019] A kind of pile driver reference of this embodiment Figure 1-5 , consists of a pile shaft 1, a hollow hammer 2 and an anvil pin 3, the hollow hammer 2 covers the outer circumference of the pile shaft 1 and can slide up and down along it, the pile shaft 1 at the bottom of the hollow hammer 2 is provided with intervals for allowing the anvil to The through hole 4 through which the pin 3 passes, and the anvil pin 3 passes through the through hole 4 and is fixed on the pile rod 1;

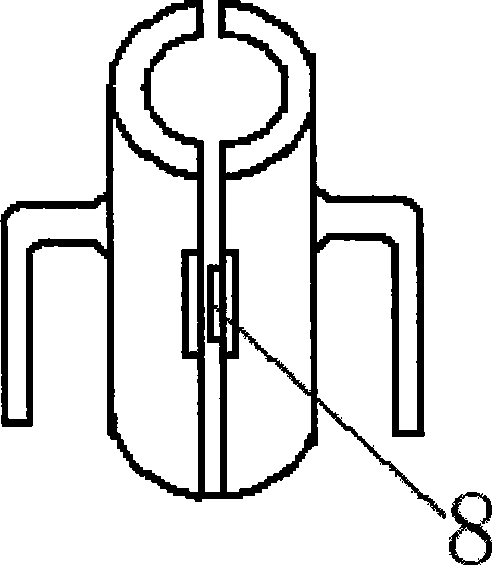

[0020] The hollow hammer 2 can be opened and closed, one side of which is provided with a hinge shaft 7 which can be opened and closed, and the other side is provided with a clip spring 8, through the joint use of the hinge shaft 7 and the clip spring 8, the hollow hammer 2 can be opened and closed. Opening and closing, thereby avoiding the trouble that the hollow hammer 2 must penetrate into the pile 1 from top to bottom;

[0021] The number of through-holes 4 set on the pile 1 depends on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com