Split backdoor hinge of automobile

A bisected, hinged technology, applied in pinned hinges, vehicle parts, door/window accessories, etc., can solve problems such as affecting the convenience of the car and failing to meet the opening needs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

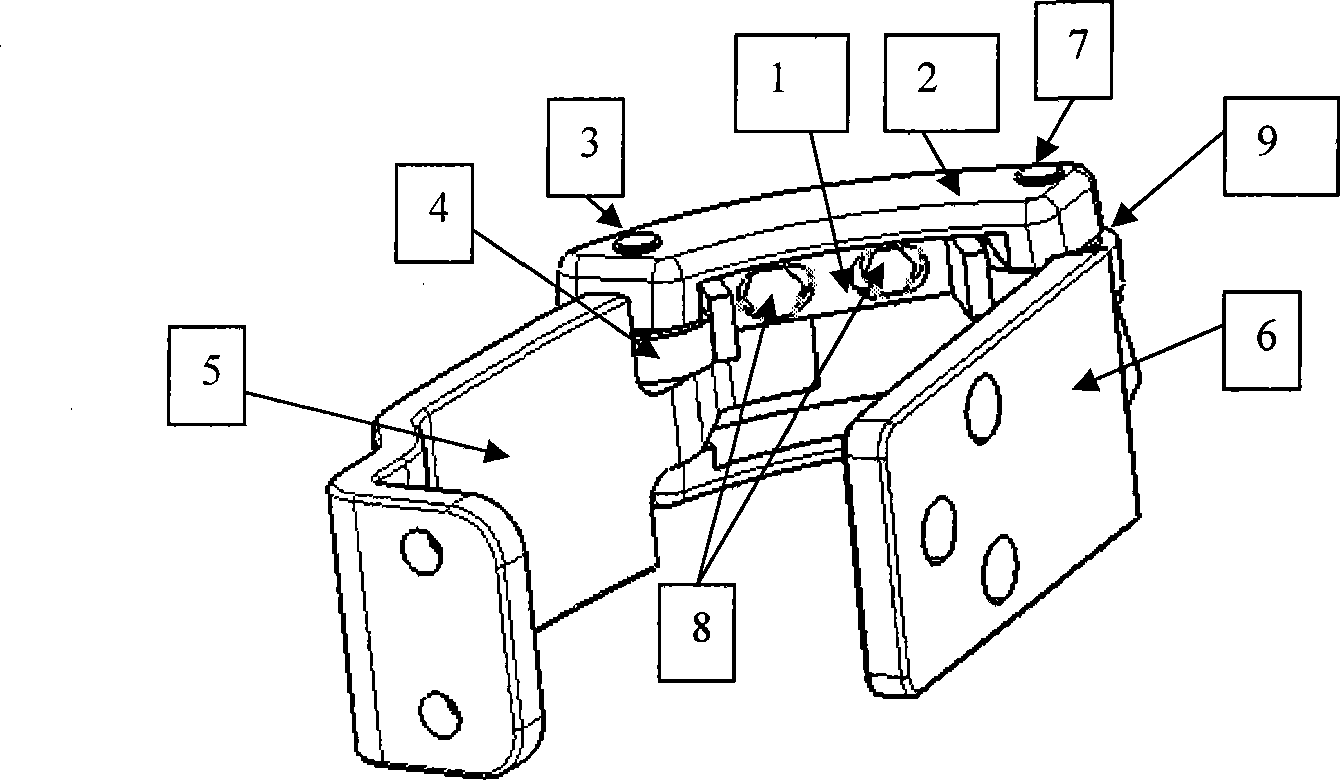

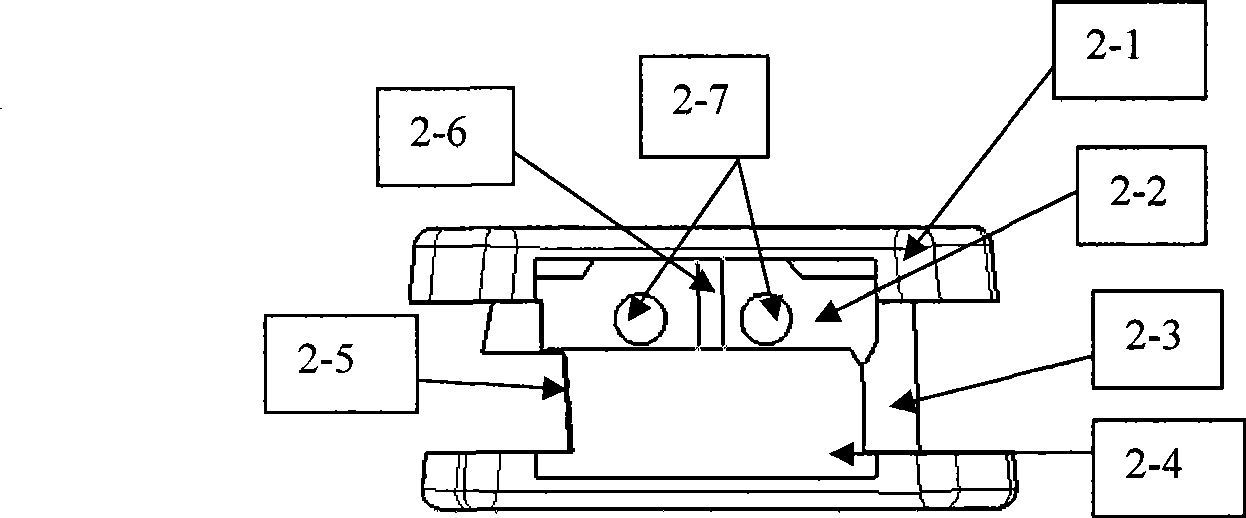

[0018] see figure 1 , the door side male hinge 5 of this hinge is connected to one end of the female hinge 2 through the first pivot pin 3, and the body side male hinge 6 is connected to the other end of the female hinge 2 through the second shaft 7. The slider 1 is slidably installed in the middle of the female hinge 2 through the screw 8 and the oblong hole, and the first cam 4 and the second cam 9 are respectively installed on the connecting ends of the male hinge 5 on the door side and the male hinge 6 on the body side and the female hinge 2 , the first cam 4 and the second cam 9 are respectively located at two ends of the slider 1 . The female hinge 2 consists of a main body 2-1, an upper plane 2-2, a side plane 2-3, a lower plane 2-4, a side plane 2-5, a groove 2-6, a threaded hole 2-7, and an outer surface 2-8 , Pin holes 2-9 form.

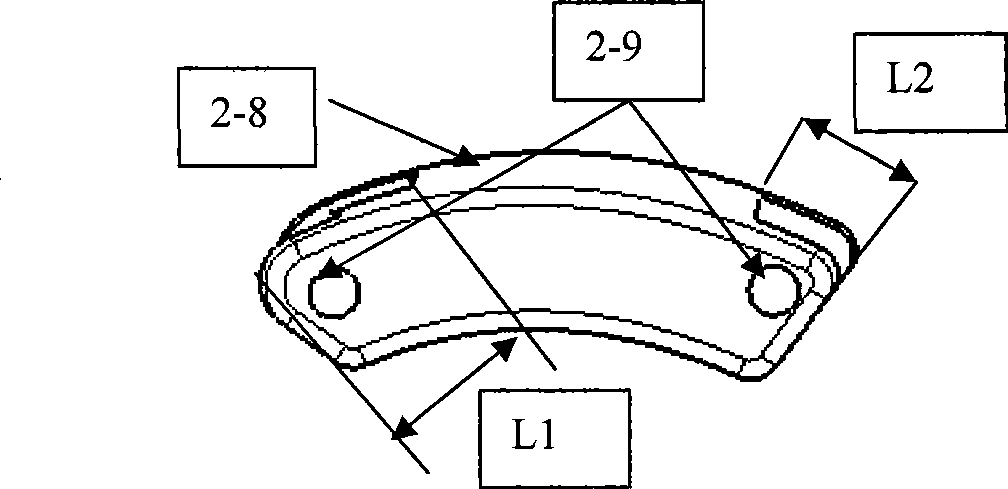

[0019] see figure 2 and image 3 , the main body 2-1 of the female hinge 2 is in the shape of "I", and the outer surface 2-8 is a cur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com