Closed-loop optic fiber gyroscope light path structure with low polarization error

A fiber optic gyro and low polarization technology, which is applied in the field of optical path structure of closed-loop fiber optic gyroscope, can solve problems such as how to use polarizer and polarizer requirements without specifying it, so as to improve optical path performance, avoid fusion angle error, and reduce polarization error Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

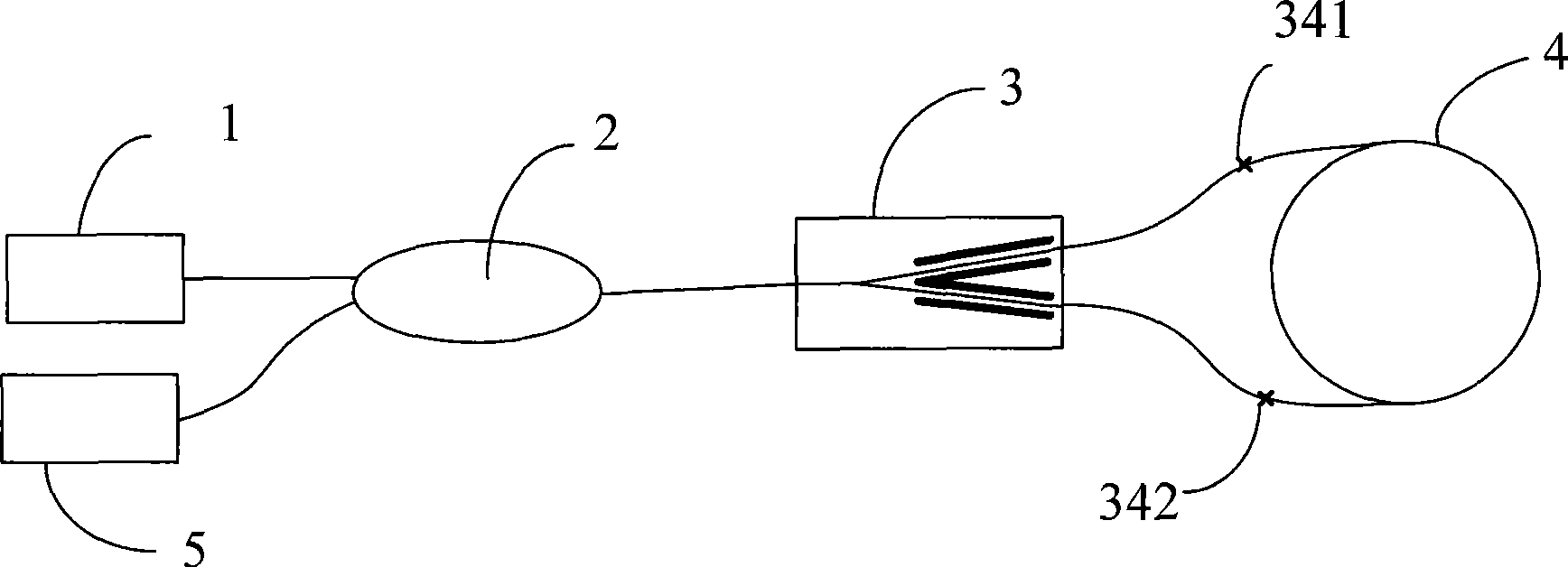

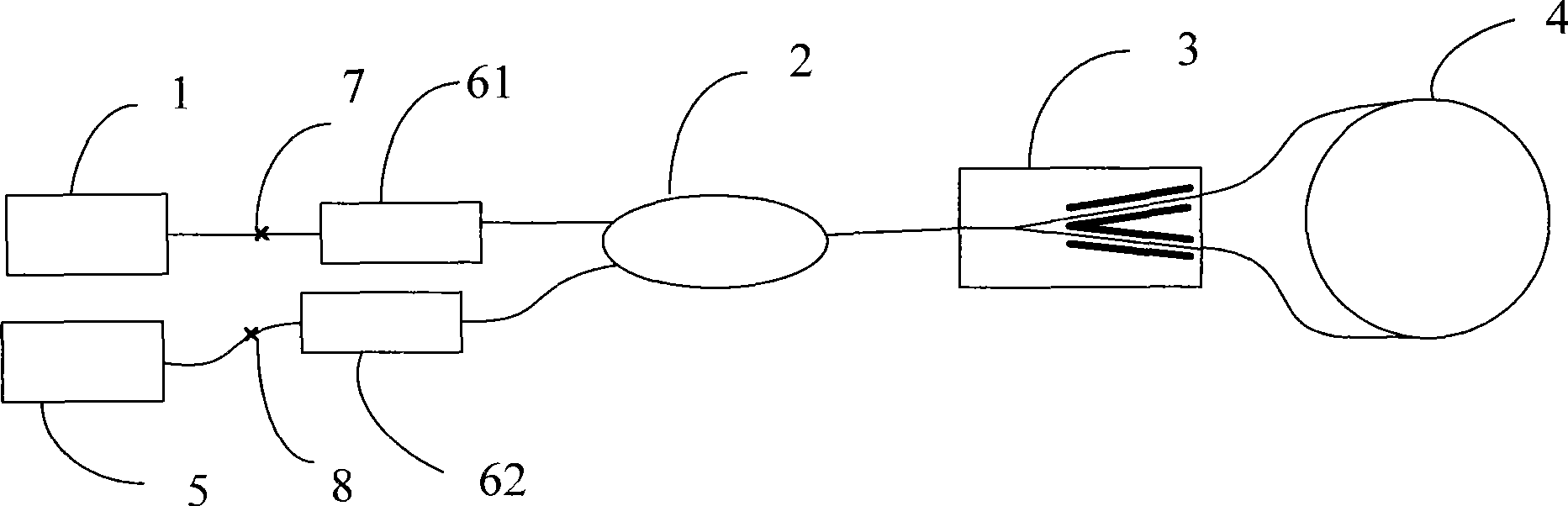

[0026] Such as figure 2 Shown is the structure of the fiber optic gyroscope optical path of the present invention, including a light source 1, a fiber coupler 2, a Y waveguide integrated optical device 3, a polarization-maintaining fiber coil 4 and a detector 5, and the light emitted by the light source 1 passes through the fiber coupler 2, The Y-waveguide integrated optical device 3 reaches the polarization-maintaining optical fiber coil 4, then reaches the Y-waveguide integrated optical device 3 in the reverse direction, and then interferes, and finally passes through the fiber coupler 2 and then reaches the detector 5, the Y-waveguide integrated optical device 3 and the polarization-maintaining optical fiber The coils 4 are directly coupled, and in order to reduce polarization errors, a polarizer 61 is arranged between the light source 1 and the fiber coupler 2 , and a polarizer 62 is arranged between the detector 5 and the fiber coupler 2 .

[0027] After adding the polar...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap